A wood-plastic composite floor tile and its production method

A wood-plastic composite and production method technology, which is applied to roads, pavement paved with prefabricated blocks, roads, etc., can solve the problems of unstable wood-plastic composite floor tiles and single functions of wood-plastic composite floor tiles. Structural stability and the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

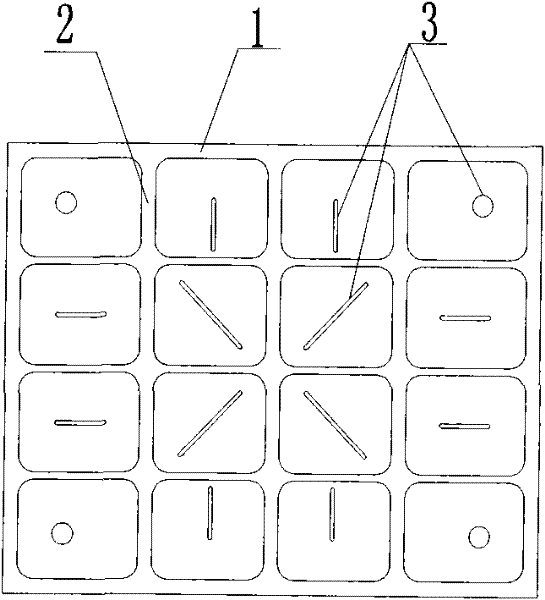

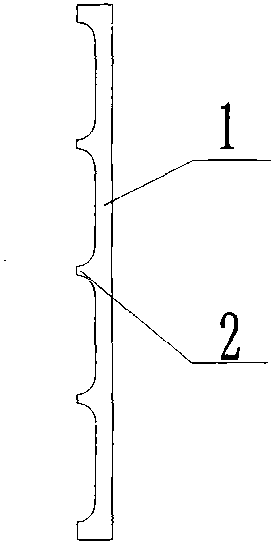

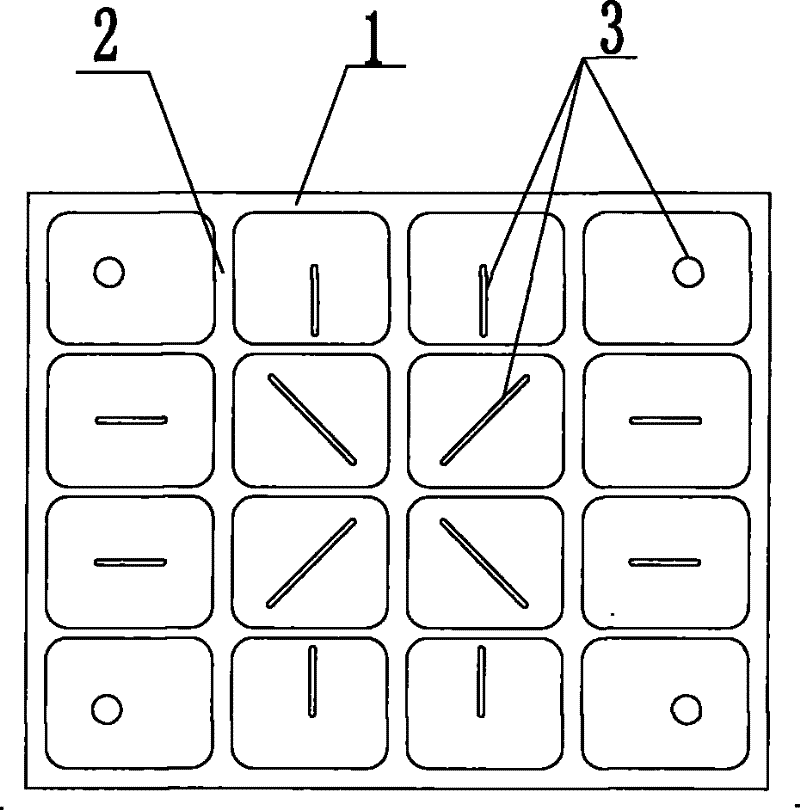

[0028] Such as figure 1 Shown: a wood-plastic composite floor tile, including a main body 1, the front of the main body 1 is provided with a layer of luminous material and stamped with a pattern, the back of the main body 1 is provided with reinforcing ribs 2 and grooves 3 are provided between the reinforcing ribs 2, The ribs 2 are right-angled, the grooves 3 are square and circular, and the luminous material in this embodiment is a rare earth aluminate phosphor.

[0029] The above-mentioned production method of a wood-plastic composite floor tile comprises the following steps:

[0030] Step 1: Mix 50% plant fiber, 30% plastic, 10% calcium carbonate, 5% linker and 5% lubricant at a high temperature of 160°C to form a mixture;

[0031] Step 2: When the plastic is semi-plasticized, pour the mixture into the mold on the die-casting machine that has been kept at a high temperature of 180°C. On one side of the mold, there is a concave mold for pressing the right-angled rib 2 and a...

Embodiment 2

[0038] The wood-plastic composite floor tile produced in this embodiment is the same as that in Embodiment 1. Another production method of a wood-plastic composite floor tile is now provided, comprising the following steps:

[0039] (1) Get 60% plant fiber, 25% plastics, 5% calcium carbonate, 5% linking agent and 5% lubricant and carry out high-temperature mixing at 160° C. to form a mixture;

[0040] (2) When the plastic is semi-plasticized, pour the mixture into the die-casting machine that has been kept at a high temperature of 180°C. On one side of the die, there is a die for pressing the right-angled reinforcing rib 2 and a bar-shaped and circular concave die. punch for groove 3;

[0041] (3) Apply 500MPa high-strength pressure to the mixture in the mold with a die-casting machine, and press it;

[0042] (4) Add luminous materials, and perform secondary 500MPa high-intensity pressure on the mixture added with rare earth aluminate phosphor;

[0043] (5) cooling the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com