Self-adaptive decompression drainage pipe pile and its preparation technology

A drainage pipe pile, self-adaptive technology, applied in the direction of sheet pile wall, foundation structure engineering, reinforced molding, etc., can solve the problems of soil damage, pore water pressure increase, fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An adaptive decompression drainage pipe pile, comprising: a pipe pile body 4 and a pile cap, at least one row of plug holes 3 distributed along the axial direction of the pipe pile body are arranged on the pipe pile body 4, and water-soluble Sexual embolism 5. In this embodiment, the water-soluble plug 5 is a polyvinyl alcohol plug.

Embodiment 2

[0029] A preparation process for an adaptive decompression drainage pipe pile, the steps are as follows:

[0030] Step 1 Reserve a through hollow hole as a plug hole around the formwork of the pipe pile for standardized production in the factory along the axial direction of the pipe pile body.

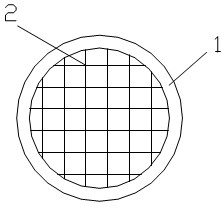

[0031] Step 2 Make several round tube molds with steel wire mesh welded inside, put the processed steel cage into the prepared template, and put the round tube mold into the reserved through hollow hole of the template against the inside The formwork is welded and fixed with the surrounding steel bars, the concrete is poured, after the formwork is sealed, it is prestressed and stretched and centrifugally formed, steam cured, and the formwork of the pipe pile produced in the factory standardized production is removed (the round pipe mold remains inside the pile body) and Weld the pile cap;

[0032] Step 3 Fill the round tubular mold on the side wall of the tubular pile with the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com