electric motor

A technology of electric motors and sub-motors, applied in the field of electric motors, can solve problems such as inefficiency, and achieve the effect of reducing the demand for capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

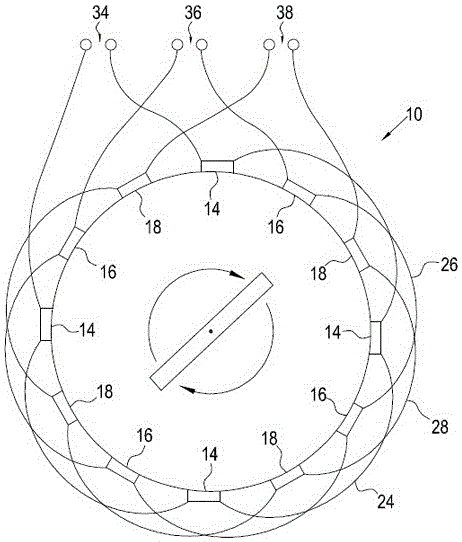

[0035] The described embodiment of the invention is an electric motor for a wheel. The electric motor is of the type having a set of coils that is part of the stator attached to the vehicle, radially surrounded by a rotor with a set of magnets for attachment to the wheels. For the avoidance of doubt, aspects of the invention are equally applicable to generators having the same arrangement. Therefore, the definition of electric motor also includes generators. Furthermore, some aspects of the invention are applicable to devices having a centrally mounted rotor radially surrounding a coil.

[0036] The physical arrangement of the specific implementation components can be referred to Figure 4 with Figure 5 to gain a clear understanding. The assembly can be described as an electric motor with built-in electronics and bearings, or it can be described as a hub motor, or hub drive, when it is built to accommodate separate wheels.

[0037] first reference Figure 4 , the assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com