A New Preparation of Frankincense and Myrrh

A technology of frankincense and vinegar, which is applied in the field of new processing of Chinese medicinal materials, can solve the problem of ineffective removal of volatile oil, etc., and achieve the effect of easy control of drying and frying temperature, ensuring product quality, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] (1) Clean selection: the frankincense (or myrrh) is moved to the clean system post to remove impurities such as bark.

[0085] (2) Coarse crushing: the frankincense (or myrrh) after cleaning is moved to the crushing station, and a sieve with an aperture of 8mm is installed on the coarse crusher, and the frankincense (or myrrh) is coarsely crushed into the size of soybeans.

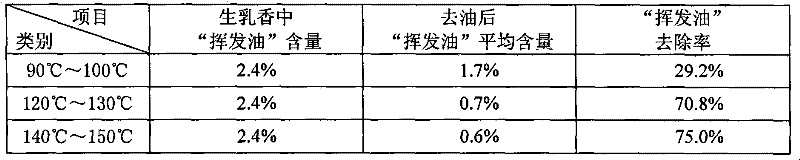

[0086] (3) Drying and degreasing: Move the coarsely crushed frankincense (or myrrh) to a drying station, spread it flat on a stainless steel baking tray lined with oil-absorbing paper, put about 1kg in each baking tray, and push it into the oven. Control the temperature at 120°C to 130°C for drying. After drying for 2 hours, the exuded oil is absorbed by oil-absorbing paper. After the frankincense in the baking tray is cooled, move the frankincense (or myrrh) on the oil-absorbing paper to a baking tray lined with clean oil-absorbing paper, and continue dry. Dry according to the above drying method...

Embodiment 2

[0090] (1) Clean selection: the frankincense (or myrrh) is moved to the clean system post to remove impurities such as bark.

[0091] (2) Drying and oil removal: move the frankincense (or myrrh) to a drying station, spread it flat on a stainless steel baking tray lined with oil-absorbing paper, put about 1kg in each baking tray, and push it into the oven. Control the temperature at 40°C to 100°C, and dry under reduced pressure. After drying for 2 hours, the exuded oil is absorbed by oil-absorbing paper. After the frankincense in the baking tray is cooled, move the frankincense (or myrrh) on the oil-absorbing paper to a baking tray lined with clean oil-absorbing paper, and continue dry. Dry according to the above drying method until the oil-absorbing paper is no longer oily, that is, there are spots of oil stains.

[0092] (4) Vinegar system: Put the oil-removed frankincense (or myrrh) into a pot, add 5% vinegar by weight of frankincense (or myrrh), mix well, adjust the tempe...

Embodiment 3

[0095] (1) Clean selection: the frankincense (or myrrh) is moved to the clean system post to remove impurities such as bark.

[0096] (2) Coarse crushing: the frankincense (or myrrh) after cleaning is moved to the crushing station, and a sieve with an aperture of 8mm is installed on the coarse crusher, and the frankincense (or myrrh) is coarsely crushed into the size of soybeans.

[0097] (3) Drying and degreasing: Move the coarsely crushed frankincense (or myrrh) to a drying station, spread it flat on a stainless steel baking tray lined with oil-absorbing paper, put about 1kg in each baking tray, and push it into the oven. Control the temperature at 130°C to 150°C for drying. After drying for 2 hours, the exuded oil is absorbed by oil-absorbing paper. After the frankincense in the baking tray is cooled, move the frankincense (or myrrh) on the oil-absorbing paper to a baking tray lined with clean oil-absorbing paper, and continue dry. Dry according to the above drying method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com