A large-scale nuclear power double-bundle steam-water separation reheating device

A steam-water separation and reheating device technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low heat transfer performance, complex structure, low efficiency, etc., to improve heat transfer performance and improve operation Power, the effect of increasing economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

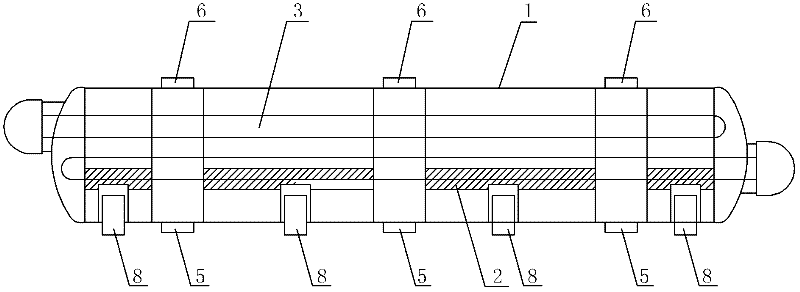

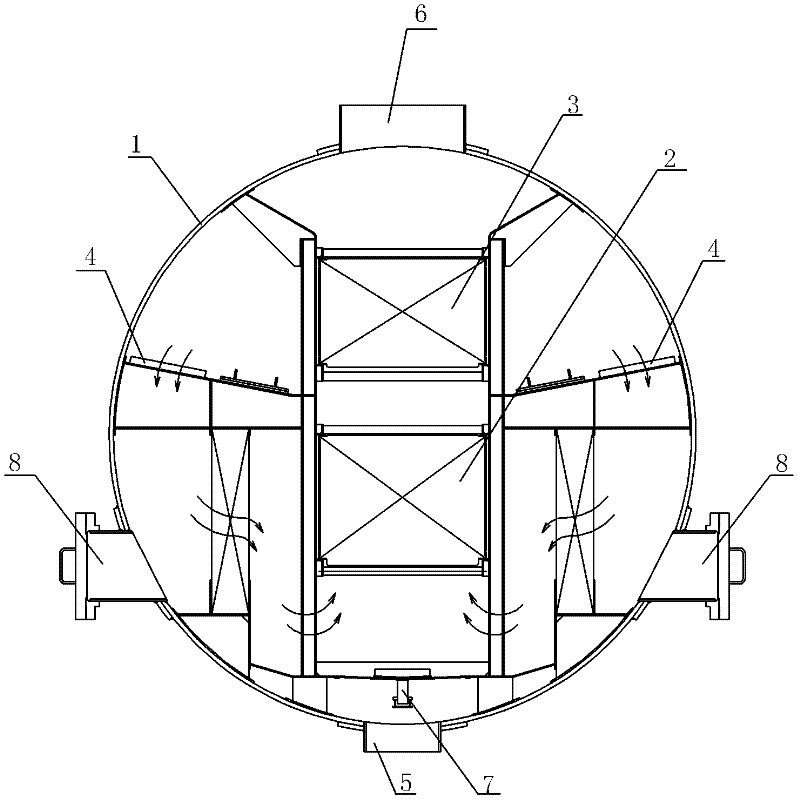

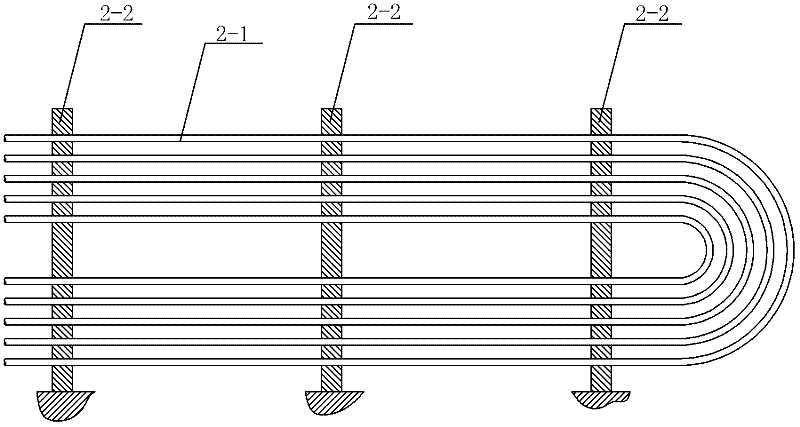

[0007] Specific implementation mode one: as Figure 1-2 As shown, the steam-water separation and reheating device described in this embodiment includes a large-scale nuclear power double-tube bundle, three-intake and four-support steam-water separation and reheating device includes a housing 1, and also includes a two-stage reheater tube bundle 2 and a steam-water separation element 3. The two-stage reheater The tube bundle 2 includes a set of U-shaped heat exchange tubes 2-1 with fins and a set of support plates 2-2, and a set of U-shaped heat exchange tubes 2-1 with fins are coaxially arranged to form a tube bundle. Pass through a group of support plates 2-2 in turn, and each support plate 2-2 is fixedly connected to the tube bundle. The steam-water separation element 3 includes an upper baffle 3-1, a lower baffle 3-2, and several corrugated plates 3 -3 and several water drop catching hooks 3-4, the upper baffle 3-1 and the lower baffle 3-2 are arranged side by side in paral...

specific Embodiment approach 2

[0008] Specific implementation mode two: as Figure 4-5 As shown, the profile of the hook head of each water droplet catching hook 3-4 of a large-scale nuclear power double-bundle steam-water separation and reheating device described in this embodiment is consistent with the shape of the outer surface of the wave crest or wave trough of the corrugated plate 3-3. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: as Figure 4-5 As shown, the lower baffle 3-2 of a large-scale nuclear power double-bundle steam-water separation and reheating device described in this embodiment is provided with a drain port 3-5. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com