Devices for handling liquids

A liquid and liquid pipeline technology, applied in the field of liquid processing devices, can solve problems such as unit integrated circulation systems that do not know condensation diagnosis, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

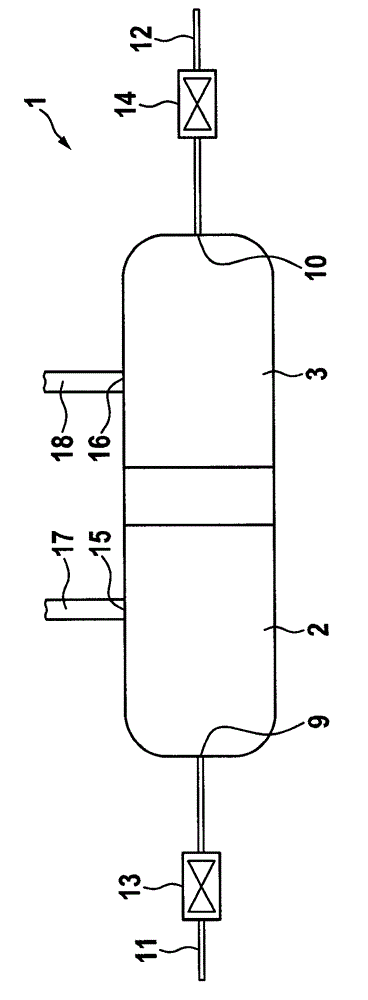

[0037] figure 1 A device 1 according to the invention for treating liquids is shown. The device 1 is suitable, for example, to improve the mixing effect of two liquids or also to accelerate the dissolution process. In addition, the device according to the invention is used for testing liquids.

[0038] In particular, the device 1 is a microfluidic device, but is not restricted to the scope of microfluidics. Rather, the device 1 according to the invention can also be produced and used as a macrofluidic device. By microfluidic device is meant here a device in at least one dimension in the submillimeter range.

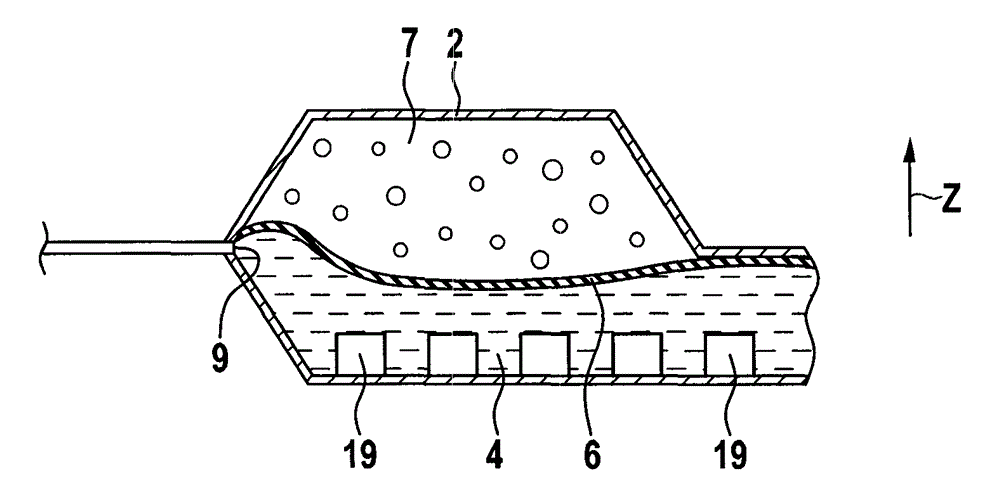

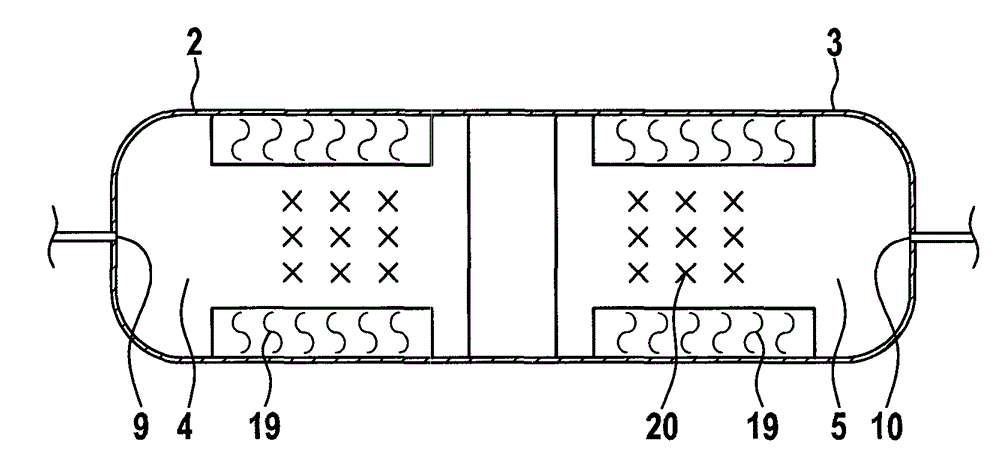

[0039] The device 1 according to the invention comprises two interior chambers, namely a first interior chamber 2 and a second interior chamber 3 . The inner chambers 2, 3 preferably consist of a polymer material. For example, the interior consists of a polymer metallized, for example by metal spraying with copper, nickel, gold or mixtures of these metals. The two i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com