Stern structure of semi-submersible crane pipe-laying vessel

A pipe-laying vessel and semi-submersible technology, which is applied in the field of marine engineering, can solve the problems of restricting the working sea conditions and air gap tension of the semi-submersible lifting pipe-laying vessel, so as to reduce the possibility of tail tilt, improve the fatigue life, control the Effects of stress levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

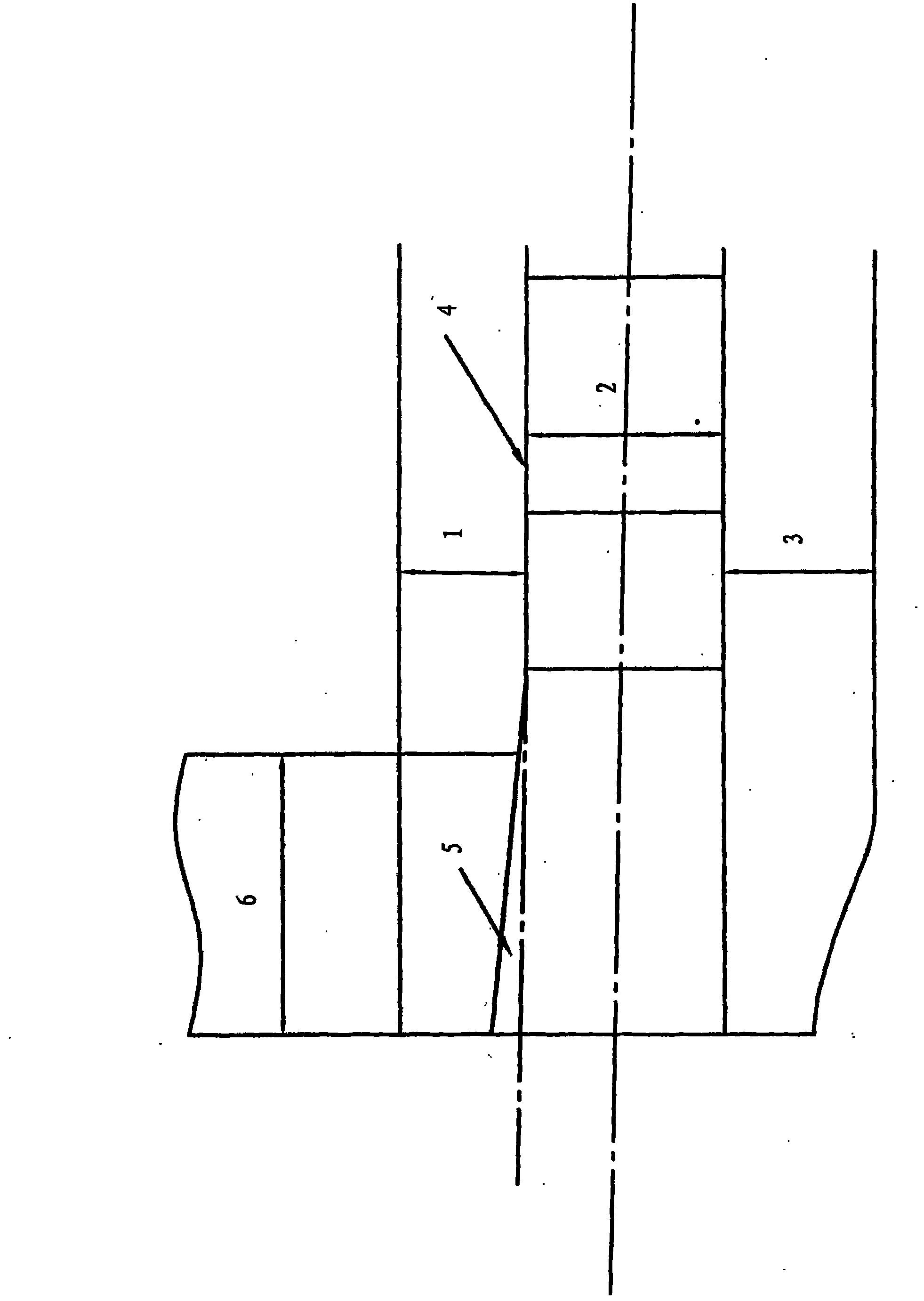

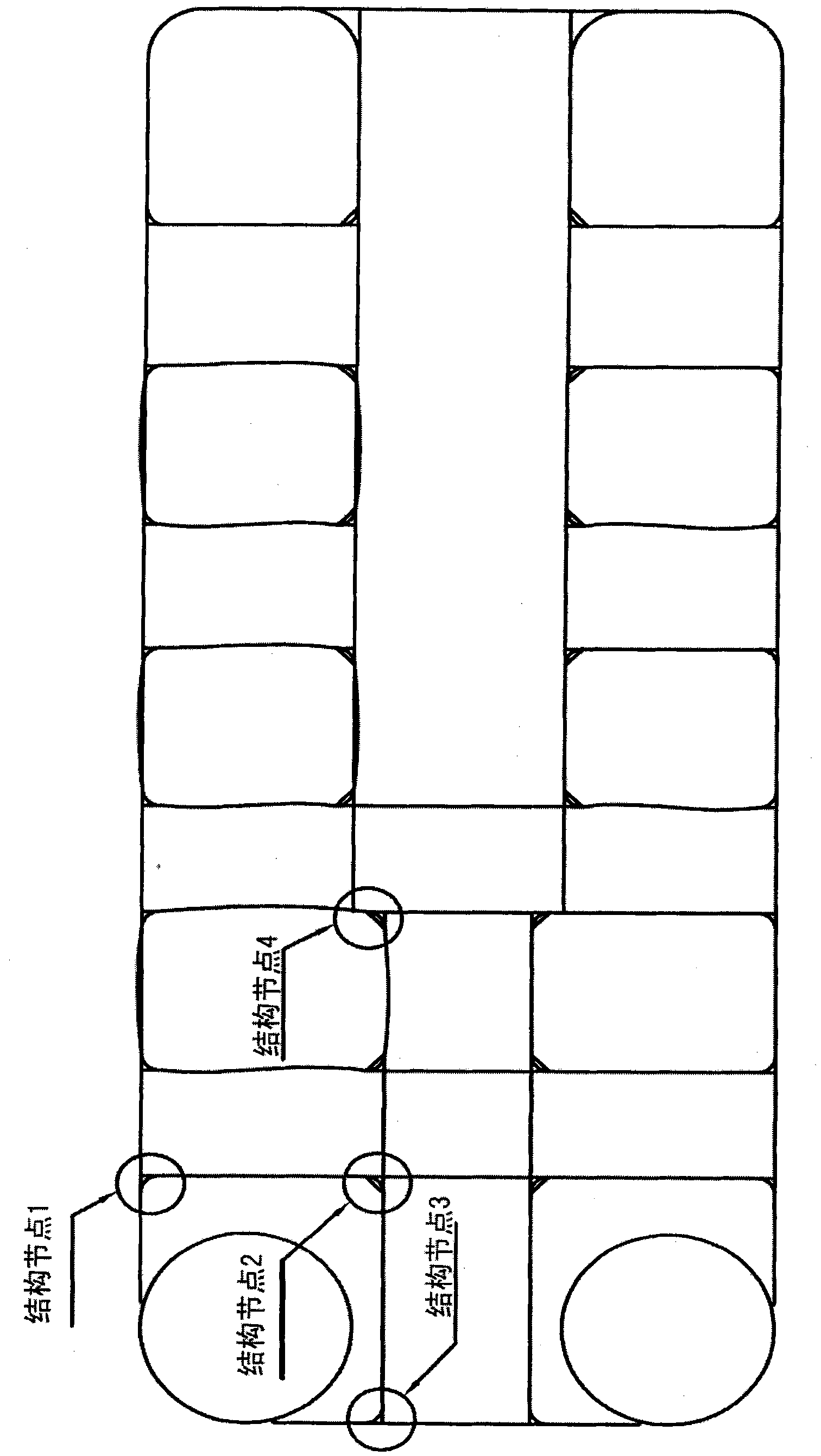

[0022] Such as figure 1 As shown, the present invention mainly includes: an upper platform 1, several columns 2 arranged in parallel on both sides below the upper platform 1, and two lower floating bodies 3 fixed on the several columns 2 arranged in parallel on both sides, and an ultra-large crane Installed at the tail of the upper platform 1; raise the profile line of the horizontal bottom 4 at the tail of the upper platform 1, that is: raise the profile line of the horizontal bottom 4 of the tail of the upper platform 1 to the set height, so that the profile line of the horizontal bottom 4 of the tail There is a set angle with the horizontal bottom 4 of the upper platform 1, and the rear air gap 5 of the upper platform 1 is increased from the external shape to improve the wind and wave resistance of the upper platform 1, and at the same time, reduce the weight of the tail structure.

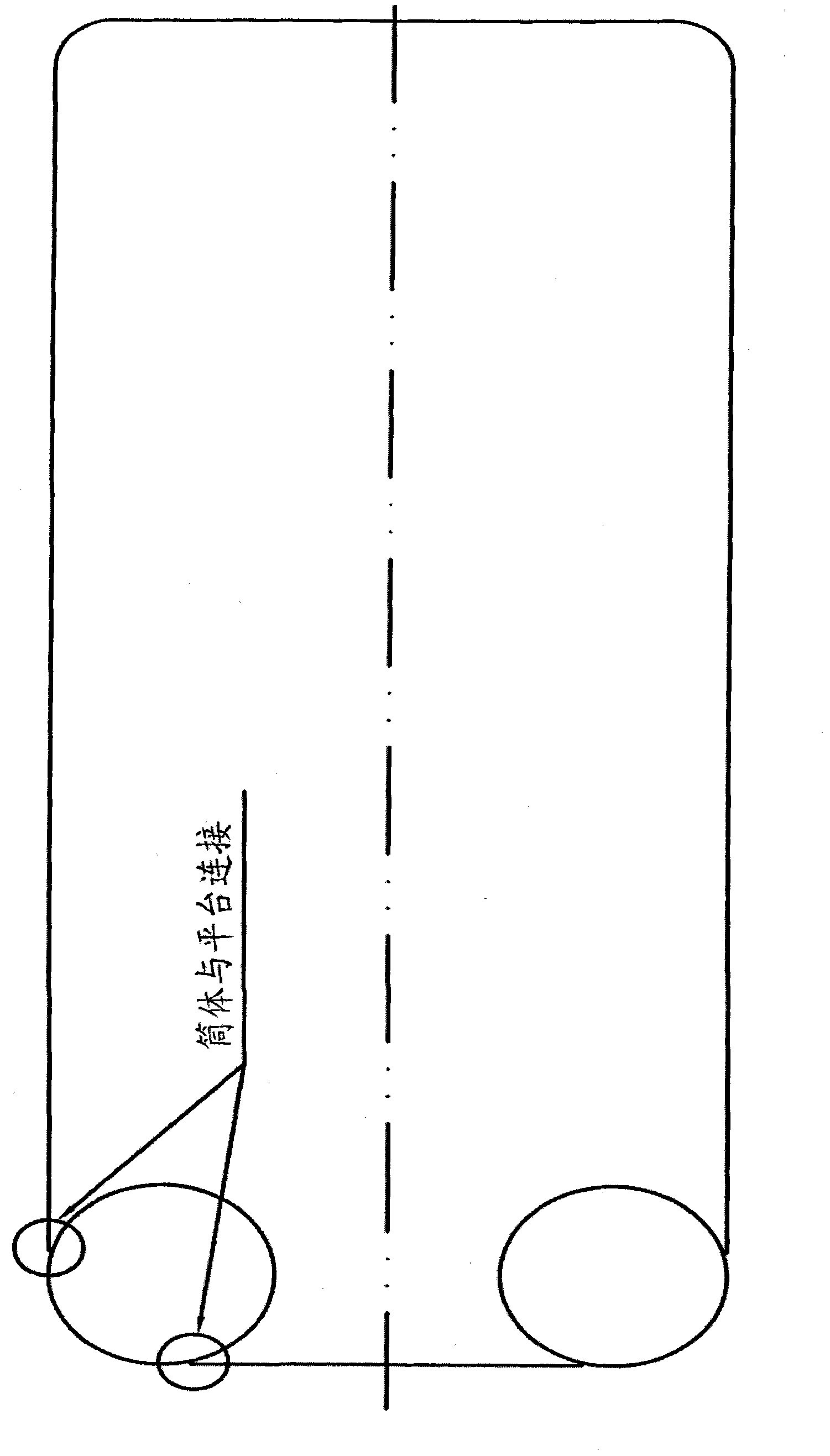

[0023] Such as figure 2 As shown, the present invention fixes the super-large crane barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com