A kind of bottomless paper labeling method and bottomless paper labeling machine

A linerless and labeling technology, applied in labeling machines, labels, packaging, etc., can solve the problems of complex mechanism, low stability, and difficulty in controlling the labeling position, and achieve low failure rate, simple structure, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present invention provides a method for labeling with bottomless paper, which is suitable for bottomless paper labels without glue on the bottom surface of the bottomless paper label, comprising the following steps,

[0040] (1) Apply glue on the bottom surface of the linerless label through the primer coating device;

[0041] (2) The bottomless label after gluing is cut off by the dynamic rotary sheet cutting mechanism controlled by the control device arranged behind the linerless label tractor;

[0042] (3) The dynamic rotary sheet cutting mechanism sends the cut labels to the vacuum conveyor belt behind the dynamic rotary sheet cutting mechanism. The roller applies the label to the surface of the item being applied.

[0043] In the above method, the control device includes a control module, a color mark sensor and an object positioning sensor, and the color mark sensor transmits the color mark information on the linerless label to the control module, and the obj...

Embodiment 2

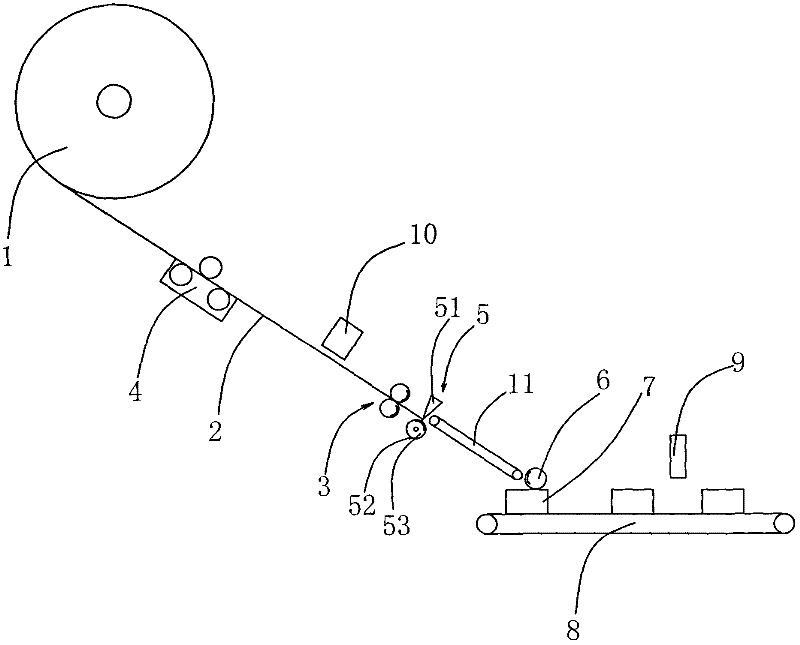

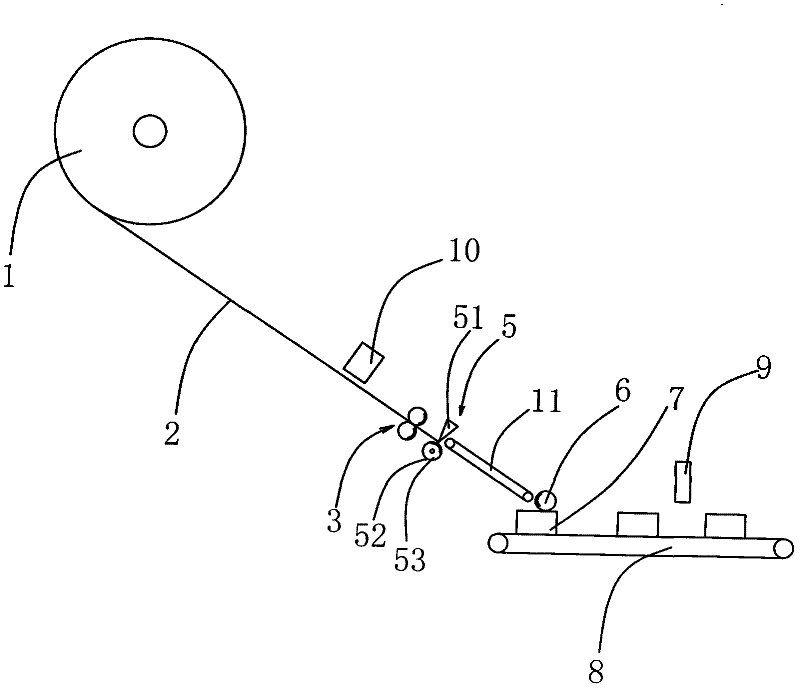

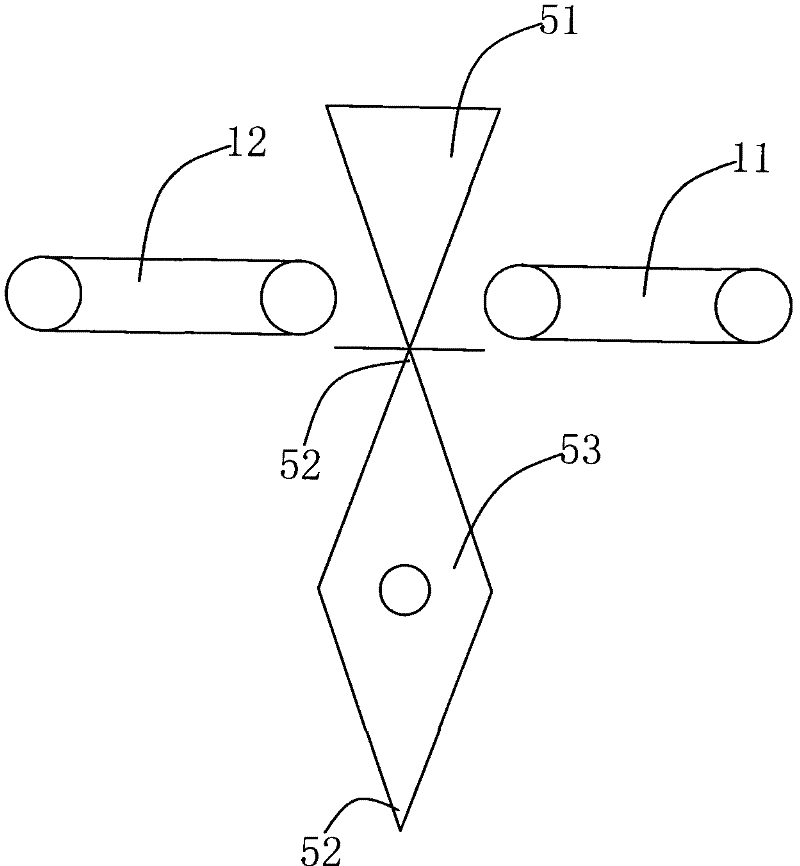

[0046] See figure 1 , figure 1 Disclosed is a linerless labeling machine suitable for linerless labels with no glue on the bottom surface of the linerless label, including a label unwinding device 1 for storing and conveying linerless labels 2; The trademark tractor 3 is located on the side of the label unwinding device 1, and is used to pull the linerless label 2 to move in one direction; It is used to apply glue to the back of the linerless label 2; the dynamic rotary sheet cutting mechanism 5 is located on the front side of the linerless label tractor 3, and is used to cut off the linerless label 2; the vacuum conveyor belt 11, the The label is transferred to the label pressing roller 6, and the label pressing roller 6 is located in front of the dynamic rotary sheet cutting mechanism 5, and is used to attach the cut label to the surface of the attached item 7; the attached item is conveyed The device 8, under the control of the control device (not shown), accurately sends...

Embodiment 3

[0049] The present invention also provides a bottomless paper labeling method, which is suitable for a bottomless paper label with glue on the bottom surface of the bottomless paper label, and is characterized in that it comprises the following steps,

[0050] (1) The bottomless label after gluing is cut off by the dynamic rotary sheet cutting mechanism controlled by the control device arranged behind the linerless label tractor;

[0051] (2) The dynamic rotary sheet cutting mechanism sends the cut labels to the vacuum conveyor belt installed behind the dynamic rotary sheet cutting mechanism. The roller applies the label to the surface of the item being applied.

[0052] In the above method, the control device includes a control module, a color mark sensor and an object positioning sensor, and the color mark sensor transmits the color mark information on the linerless label to the control module, and the object positioning sensor will be The position information of the posted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com