Method for preparing vinyl acetylene by electric field enhanced acetylene dimerization

A vinyl acetylene and electric field technology, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problem that the single-pass conversion of acetylene is not enough and the yield of vinyl acetylene is not high enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

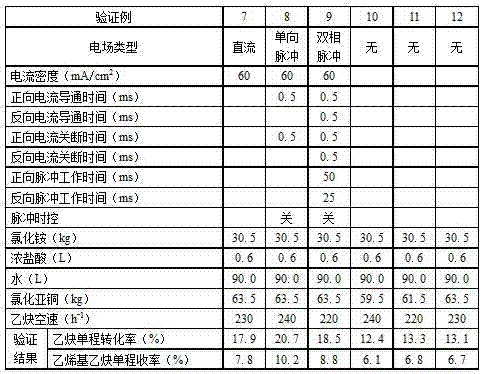

Examples

Embodiment Construction

[0011] The invention discloses a method for preparing vinyl acetylene by electric field enhanced acetylene dimerization. The catalyst used in the method is an aqueous solution prepared by cuprous chloride, ammonium chloride and hydrochloric acid. In the present invention, the component ratio of the catalyst is cuprous chloride: ammonium chloride: hydrochloric acid: water=59.5~63.5kg: 30.5kg: 0.6L: 90L; Carried out under the action, the two poles of setting up the electric field are copper electrodes installed in the reaction device; the steps of the method are as follows:

[0012] ① Under constant temperature conditions of 80°C±5°C, blow nitrogen into the reaction device to remove the air in the reaction device (usually, the time for removing air is not less than 25 minutes); Component proportioning, first add ammonium chloride and water to the reaction device; then while continuing to feed nitrogen to get rid of air, bubbling and stirring to allow ammonium chloride to fully d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com