Bubble tower reactor for enhancing acetylene dimerization

A bubbling tower and reactor technology, which is applied in the field of bubbling tower reactors for strengthening acetylene dimerization, can solve the problems of vinyl acetylene selectivity decline, seriousness, fluid back-mixing, etc., so as to reduce further contact and equipment costs. Low, selectivity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

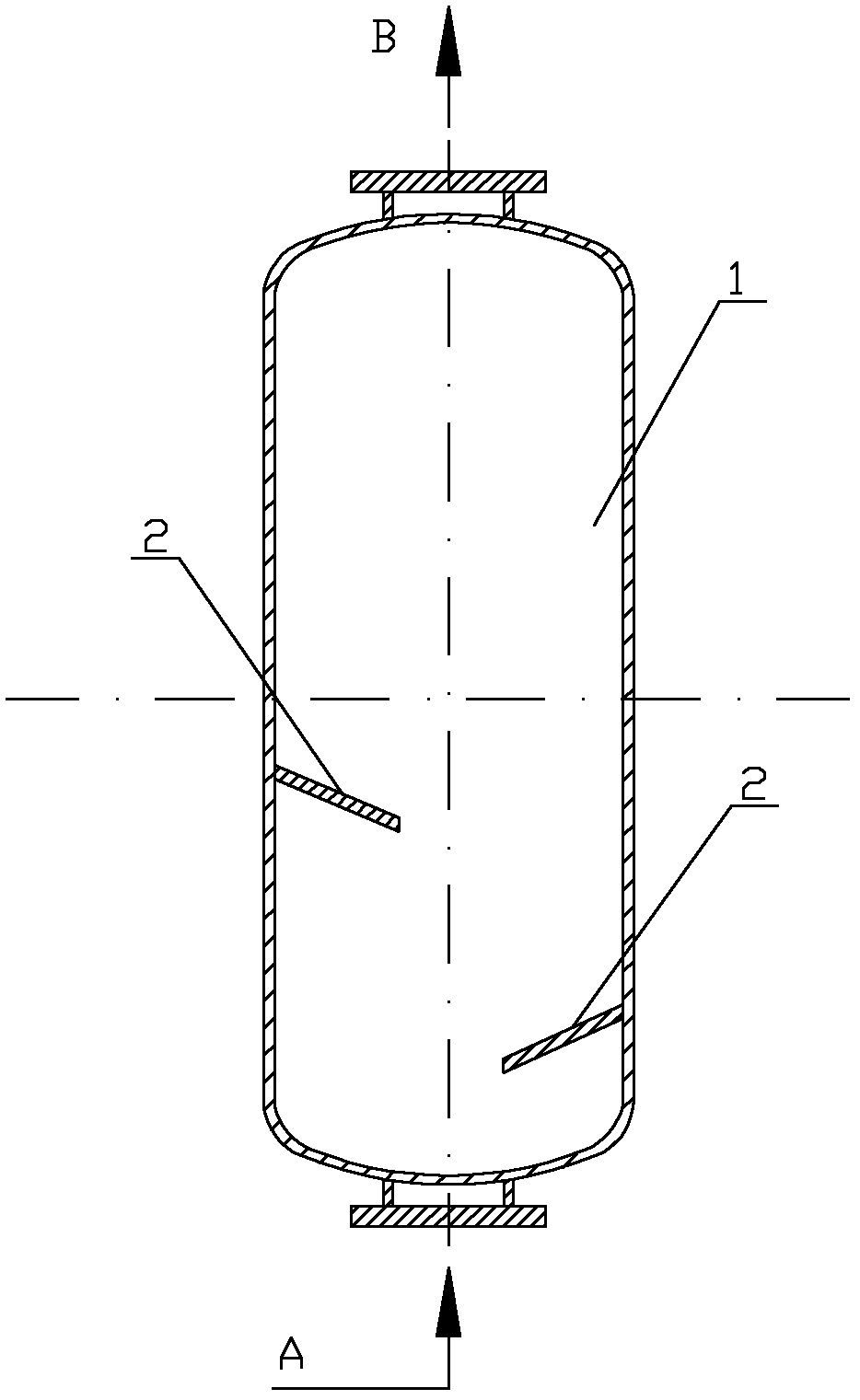

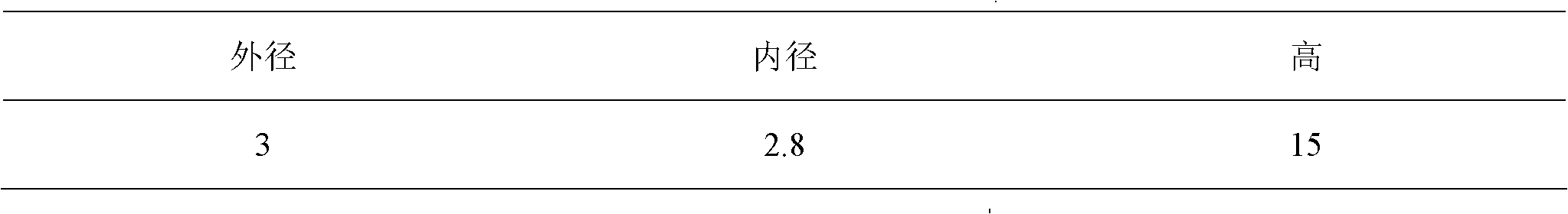

[0026] The dimensions of the bubble column reactor for enhanced acetylene dimerization are shown in Table 1.

[0027] The bubble column reactor size (unit: m) of the strengthened acetylene dimerization of table 1 specific example 1

[0028]

[0029] The liquid level height of the bubble column reactor liquid for enhanced acetylene dimerization is 5m.

[0030] The installation position of the baffle is: the baffle 2 is installed on the inner wall of the tower below the bubble column reactor liquid of the enhanced acetylene dimerization, and the bubble column reactor 1 of the enhanced acetylene dimerization in the present embodiment has 4 pieces such as figure 2 Rectangular baffle 2 shown; the material of said baffle 2 is the same as that of the bubble column; the thickness of said baffle 2 is 1 / 2 of the wall thickness of the bubble column; the width of said baffle 2 is 3 times of the wall thickness of the bubble column; the angle between the baffle plate 2 and the tower wa...

specific Embodiment 2

[0032] The size of the bubble column reactor for strengthening acetylene dimerization is as in specific example 1.

[0033] The liquid level height of the bubble column reactor liquid for strengthening acetylene dimerization is as in specific example 1.

[0034] The installation position of the baffle plate is: the baffle plate 2 is installed on the inner wall of the tower below the bubble column reactor liquid of the enhanced acetylene dimerization, and the bubble column reactor 1 of the enhanced acetylene dimerization in the present embodiment has 8 pieces such as figure 2 Rectangular baffle 2 shown; the material of said baffle 2 is the same as that of the bubble column; the thickness of said baffle 2 is 1 / 2 of the wall thickness of the bubble column; the width of said baffle 2 is 3 times of the wall thickness of the bubble column; the angle between the baffle plate 2 and the tower wall is 60 degrees; the length of the baffle plate 2 / diameter of the bubble column=0.4; The ...

specific Embodiment 3

[0036] The size of the bubble column reactor for strengthening acetylene dimerization is as in specific example 1.

[0037] The liquid level height of the bubble column reactor liquid for strengthening acetylene dimerization is as in specific example 1.

[0038] The installation position of the baffle is: a baffle 2 is installed on the inner wall of the tower below the bubble column reactor liquid for strengthening acetylene dimerization, and the bubble column reactor 1 for strengthening acetylene dimerization in the present embodiment has 3 pieces such as figure 2 Rectangular baffle 2 shown; the material of said baffle 2 is the same as that of the bubble column; the thickness of said baffle 2 is 1 / 2 of the wall thickness of the bubble column; the width of said baffle 2 is 3 times of the wall thickness of the bubble column; the angle between the baffle plate 2 and the tower wall is 60 degrees; the length of the baffle plate 2 / diameter of the bubble column=0.4; The distance b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com