Anti-counterfeiting microstructure pigment and manufacturing process thereof

A manufacturing process and microstructure technology, which is applied in the field of anti-counterfeit microstructured pigments and its manufacturing process, can solve problems such as limitations in the field of use, and achieve reliable anti-counterfeiting effects, lower application thresholds, and complex manufacturing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

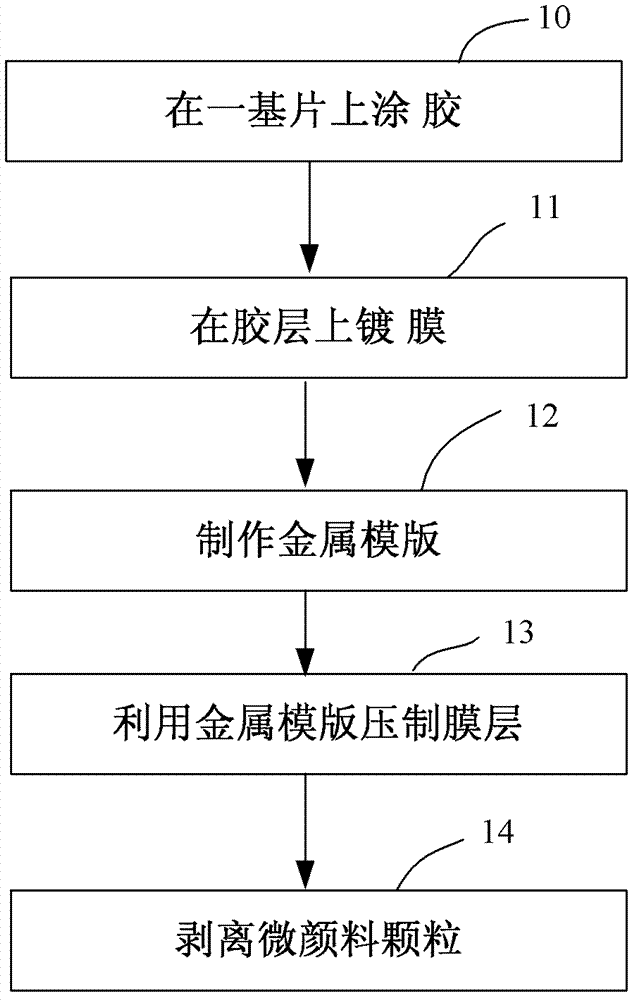

[0017] The manufacturing process of the anti-counterfeit microstructure pigment of the present invention first adopts the deposition technology to make an optical thin film on the substrate, and then uses the microstructure technology to make a metal template with a micro-graphic concave-convex groove structure. Through the stamping of the metal template on the optical film, the sheet-shaped optical film is stamped into fragments with a microstructure on the surface of the metal template, and finally the specific shape of the microstructure is peeled off from the substrate to become a microscopic pigment with optical anti-counterfeiting function . The anti-counterfeiting pigment of the present invention can be designed to have specific and recognizable geometric shapes, text patterns, etc., and the surface of the pigment particles can also carry specific text and pattern information, which has an optical anti-counterfeiting effect. Anti-counterfeiting pigments of different sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com