led packaging method and led

A technology of LED packaging and LED chips, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reduced luminous efficiency of phosphors, low excitation efficiency of phosphors, uneven distribution of phosphor layers, etc., so as to avoid the decline of luminous efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

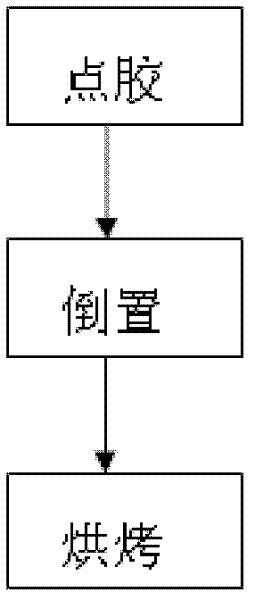

[0032] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

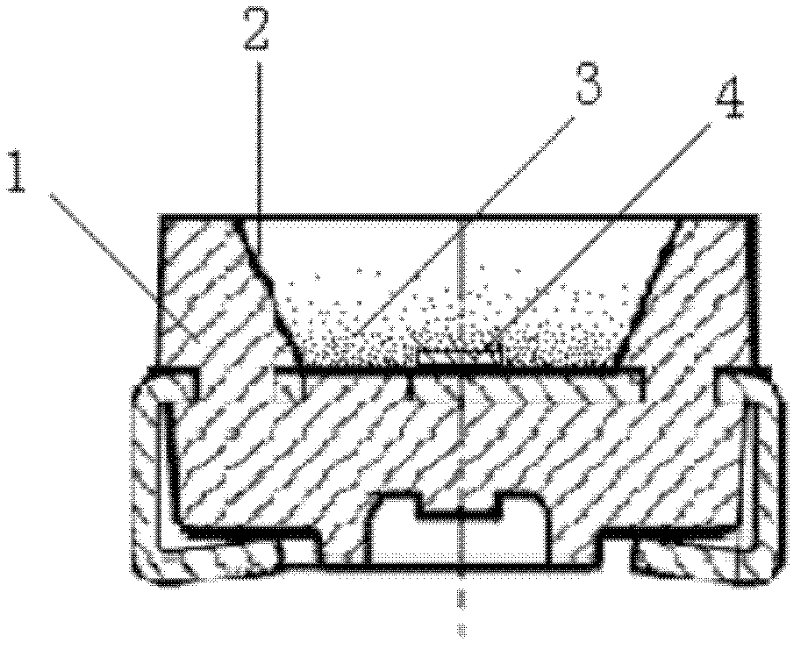

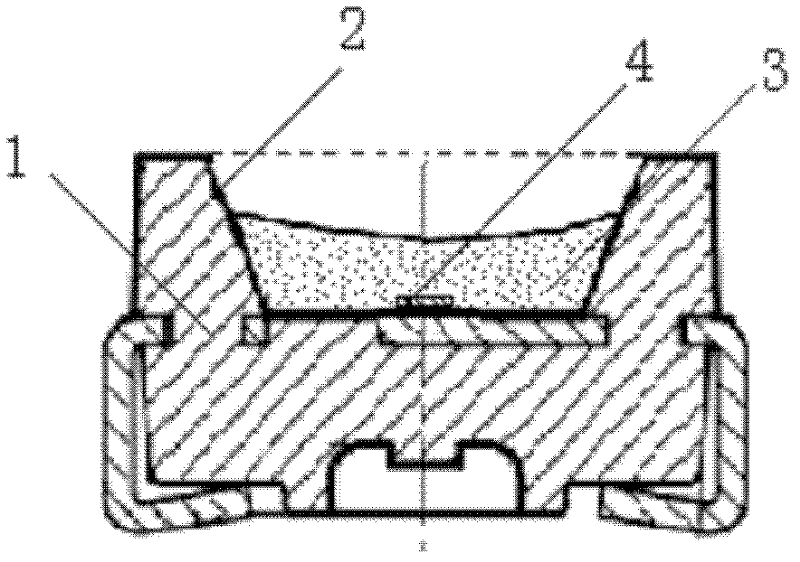

[0033] The LEDs in this example also include figure 1 As shown in the bracket 1 with a cavity 2 , the bottom of the cavity 2 is provided with a metal layer, and the LED chip 4 is arranged on the metal layer at the bottom of the cavity 2 . In order to better understand the present invention, the nouns used hereinafter are specifically explained below:

[0034] The colloid in this example refers to the colloid used for LED packaging, such as silica gel, silicone resin or epoxy resin;

[0035] The fluorescent glue in this example refers to the fluorescent glue that is prepared by mixing phosphor powder with glue in a certain proportion. The phosphor powder in the fluorescent glue is evenly distributed. It is worth noting that the fluorescent glue in this example can be a single phosphor or multiple A combination of phosphors.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com