A numerical control polishing method for the blade surface of the integral blisk

An integral blisk and blade technology, used in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of difficulty in ensuring accuracy, single use, uneven removal during polishing, and improve polishing. The effect of machining accuracy and improving polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] This embodiment is a numerically controlled polishing method for the blade profile of an integral blisk. Applying the numerical control polishing method to polish the overall blisk blade surface of a certain type of aero-engine, the specific steps are as follows:

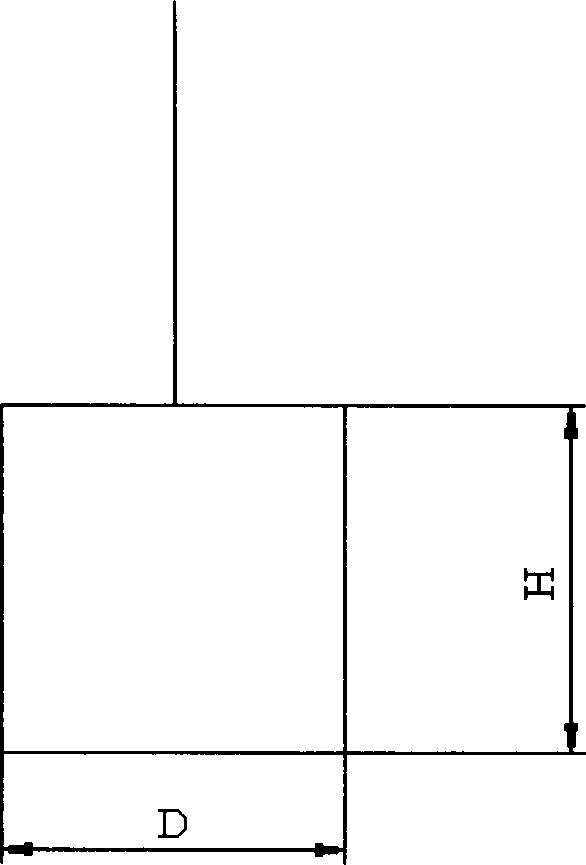

[0032] The first step is to measure the size of the polishing wheel; according to the selected polishing wheel, use a vernier caliper to accurately measure the diameter D and height H of the cylindrical polishing wheel, such as figure 1 shown;

[0033] The second step is to determine the polishing line spacing; in order to ensure that the polishing wheel can be thrown smoothly to each area of the blisk blade, and taking into account the work efficiency, the line spacing is determined to be one-half of the height of the polishing wheel;

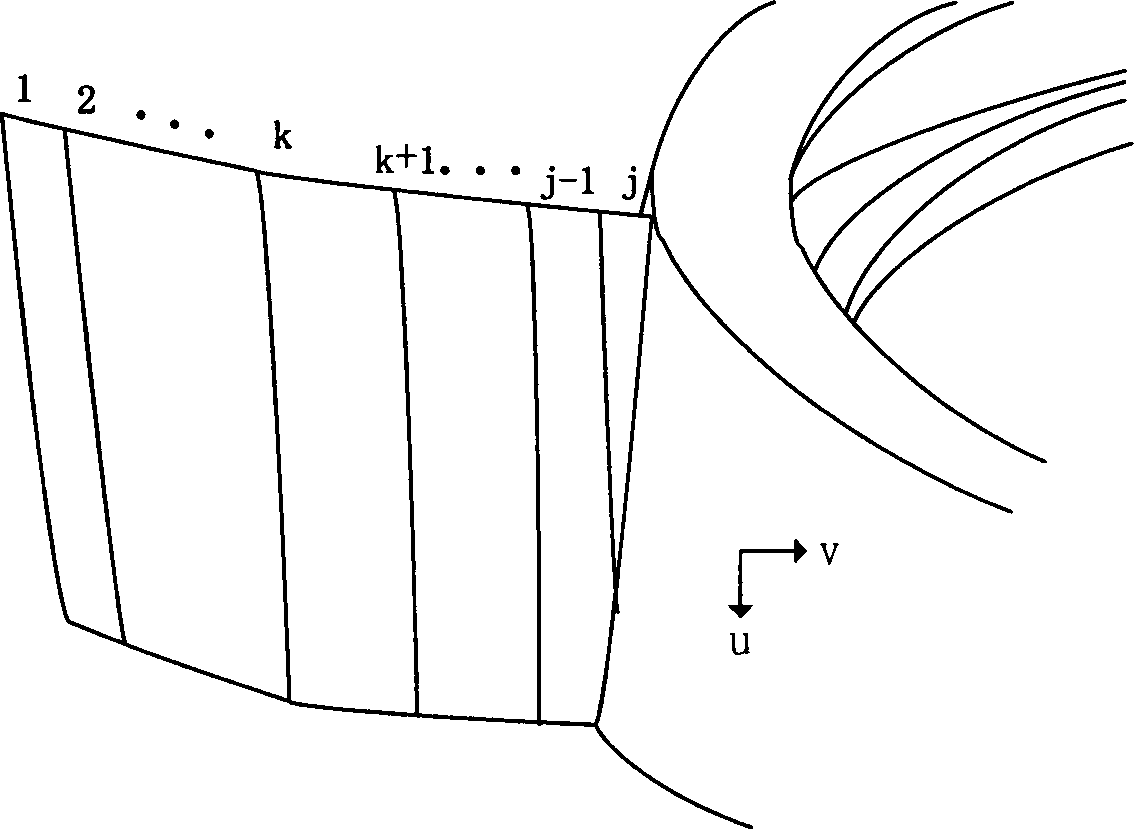

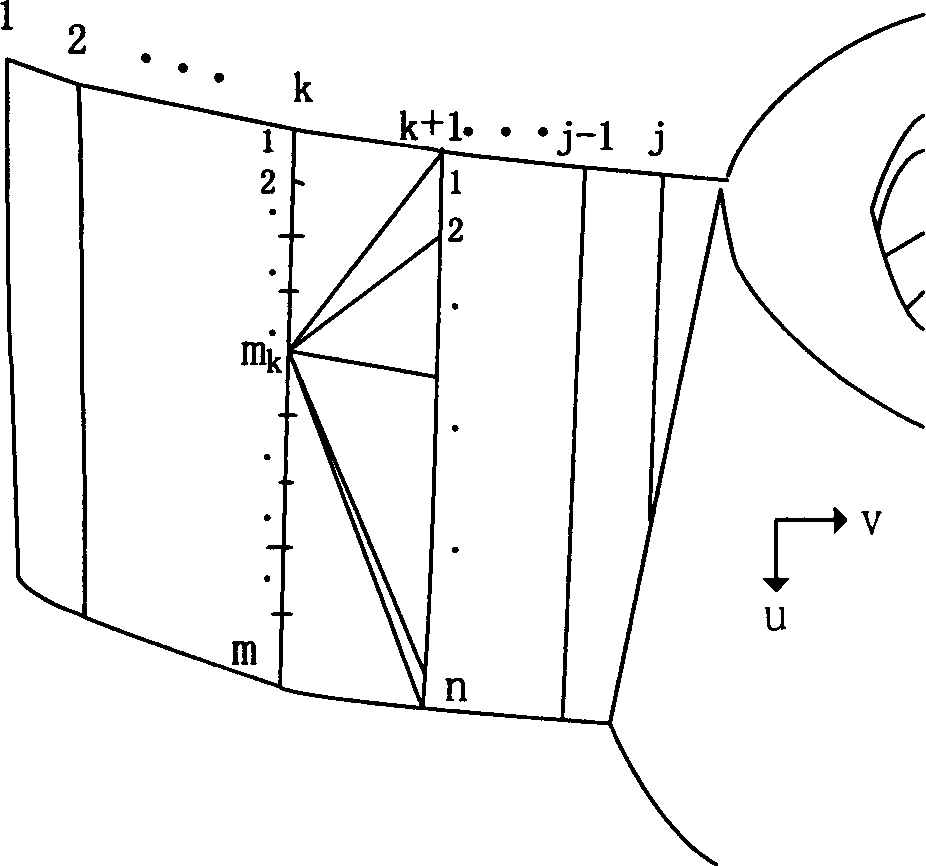

[0034] The third step is to plan the polishing path; record the direction of the runner line as u, and the direction perpendicular to the runner line as v. The longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com