Two-way type armature shaft automatic polishing device

An automatic polishing and armature shaft technology, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding machines, etc. Improve polishing accuracy, uniform feed, and reduce abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

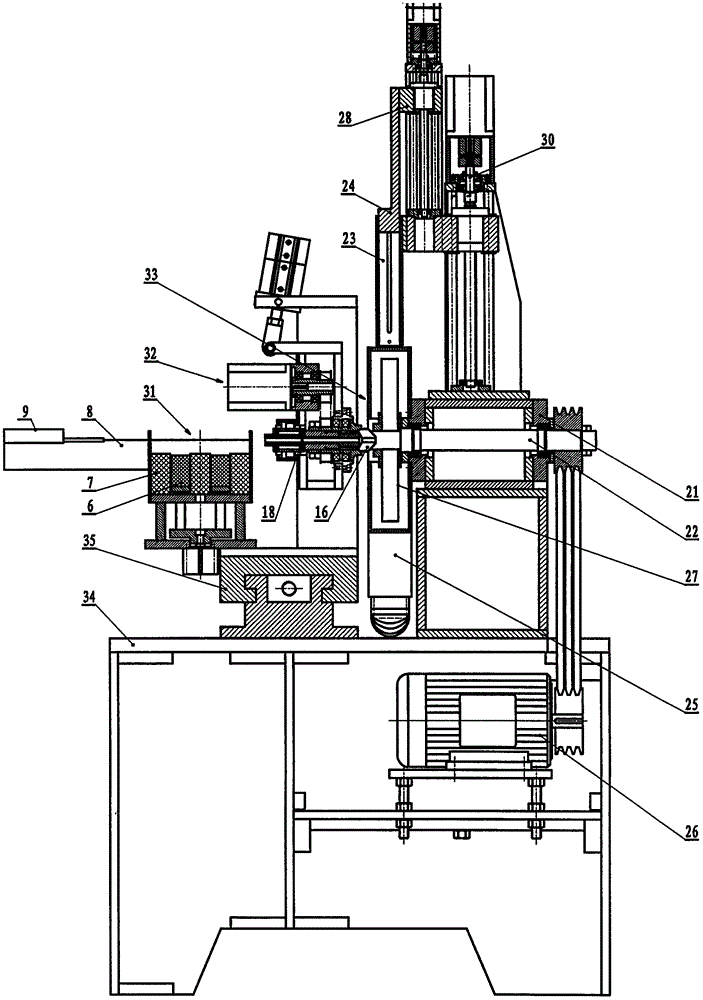

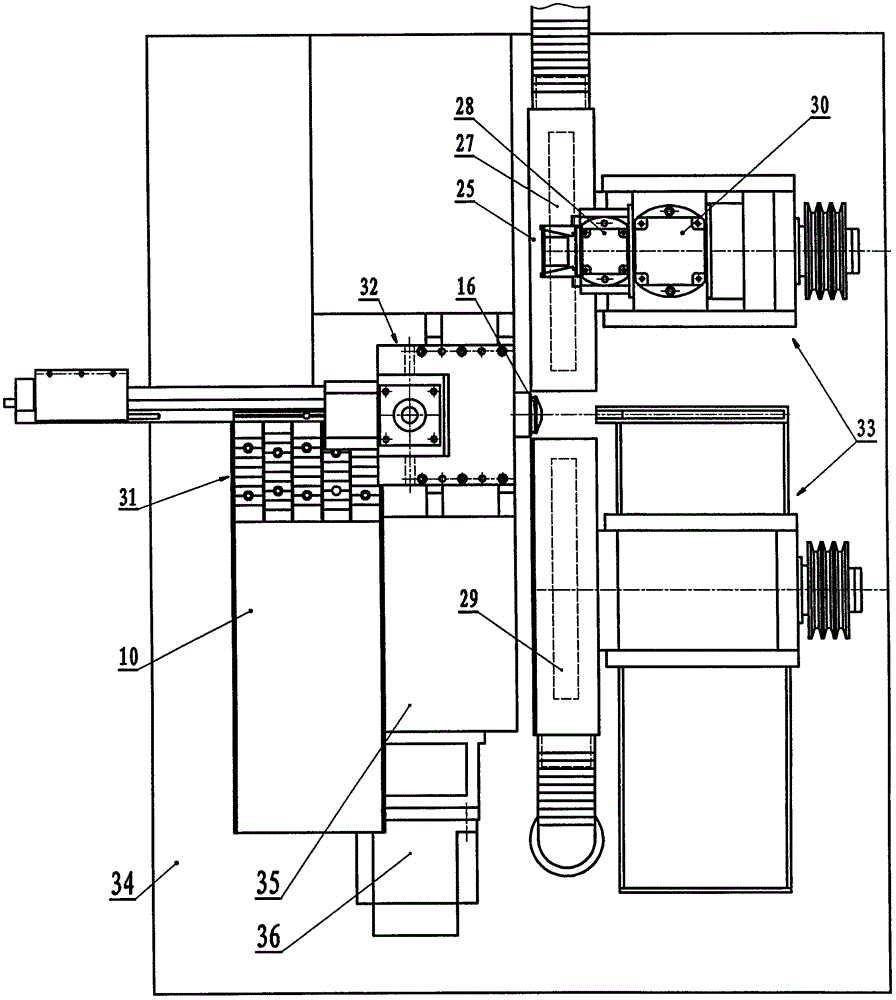

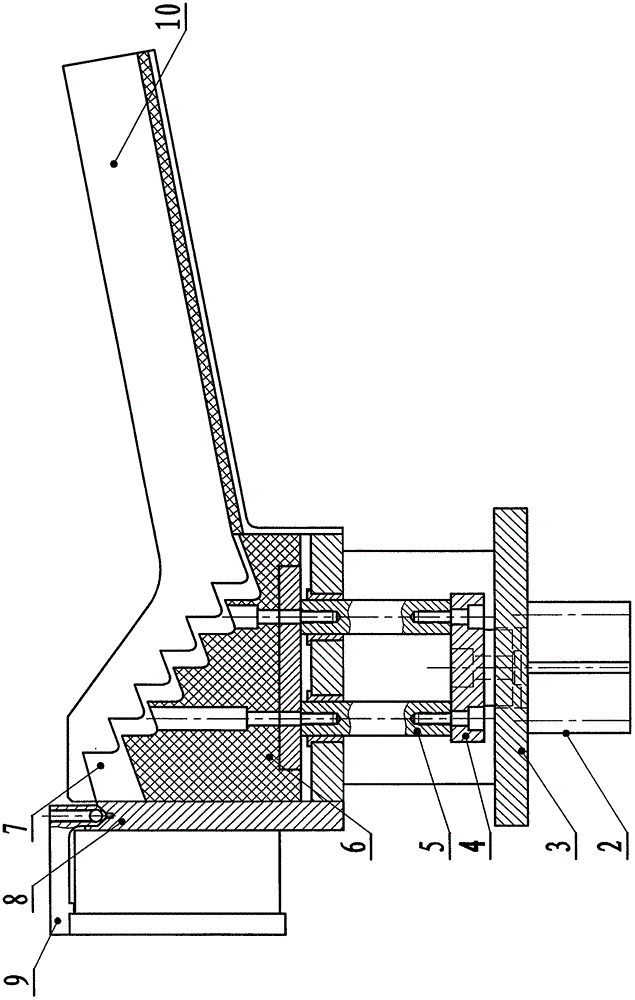

[0014] refer to figure 1 , figure 2 , the two-way armature shaft automatic polishing device of the present invention comprises a polishing support 21, a polishing wheel (covered by a dust cover 25), and the polishing wheel is connected to a polishing power drive source 26 through a polishing mandrel 22, and the polishing wheel Divided into a cloth polishing wheel 27 at the rear (waxing and polishing of the armature shaft) and a fiber material polishing wheel 29 at the front (deburring of the armature shaft), the top of the cloth polishing wheel 27 passes wax The extruding block 24 in the box 23 and the wax box is connected with the extruding wax assembly 28 (for the combination driving mode of the screw mandrel connection block). The cloth polishing wheel and the fiber material polishing wheel are independently driven by corresponding polishing power drive sources.

[0015] The armature shaft automatic feeding swing polishing machine applied in the present invention also in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com