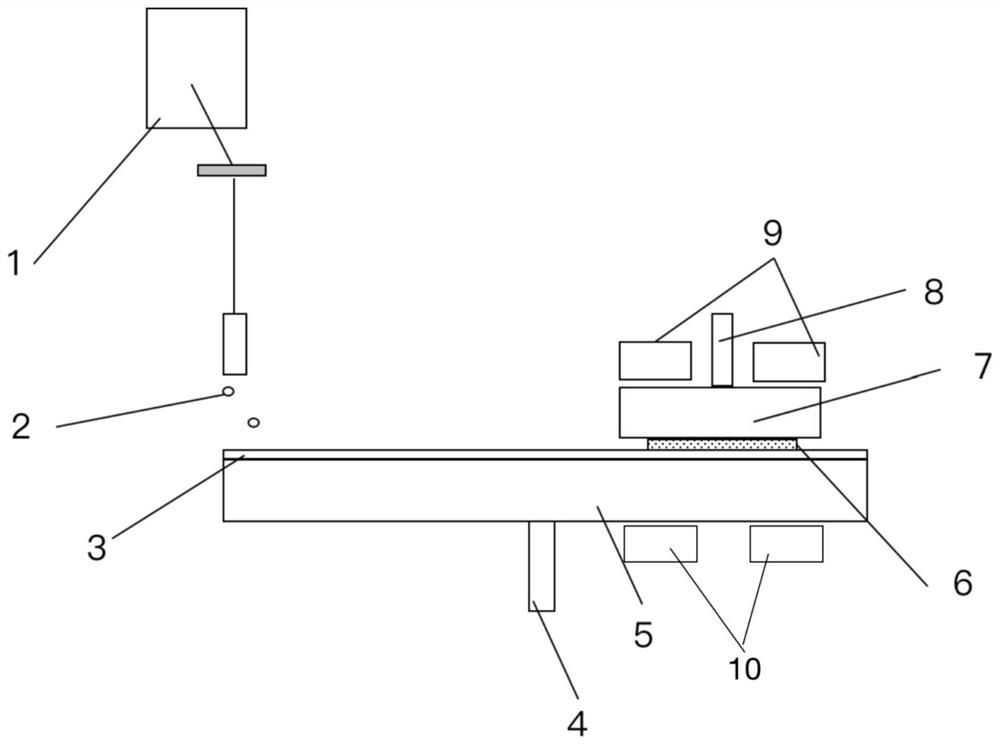

A non-mechanical contact magnetic in-situ ultrasonic vibration chemical mechanical polishing method

A non-mechanical contact, ultrasonic vibration technology, used in polishing compositions containing abrasives, grinding machine tools, metal processing equipment, etc., can solve the problems of difficulty in ensuring the stability of the resonance mode, low vibration conduction efficiency, etc., to improve the polishing effect. , the effect of good vibration distribution uniformity, strong flexibility and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The experimental materials used in this embodiment are as follows:

[0074] Ferromagnetic particles: Fe modified with trisodium citrate produced by Zhongke Leiming (Beijing) Technology Co., Ltd. 3 o 4 Microspheres (average diameter 7nm);

[0075] Polishing liquid: Polishing liquid with high selectivity ratio silicon rough polishing produced by Anji Microelectronics Technology (Shanghai) Co., Ltd.;

[0076] Substrate: a single crystal silicon wafer with a diameter of 25.4mm and a surface roughness of 0.5μm;

[0077] Substrate carrier: made of ABS engineering plastics, with a diameter of 100mm and a thickness of 8mm;

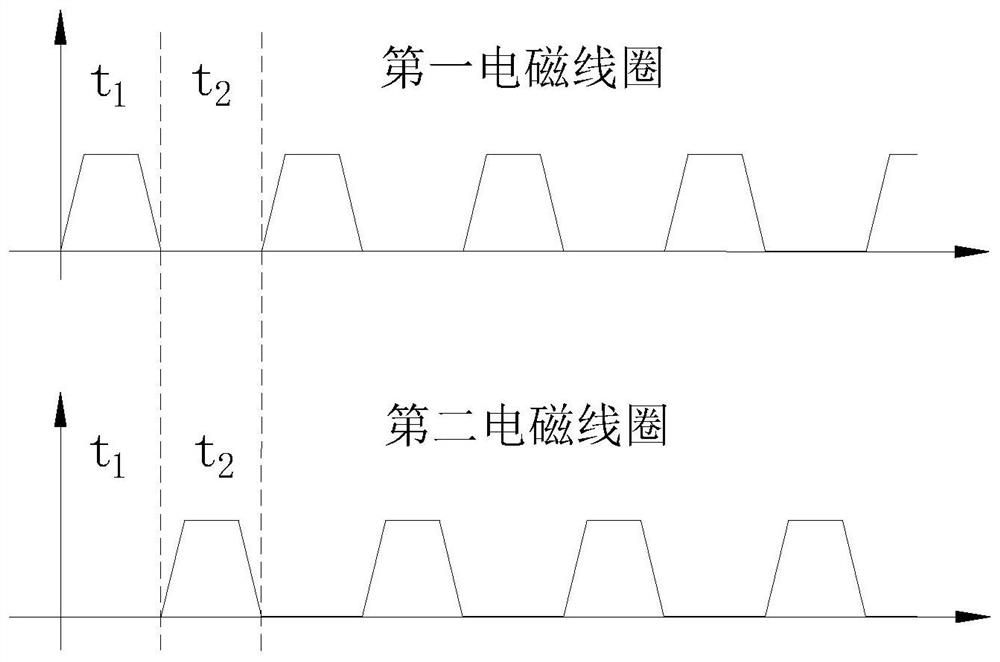

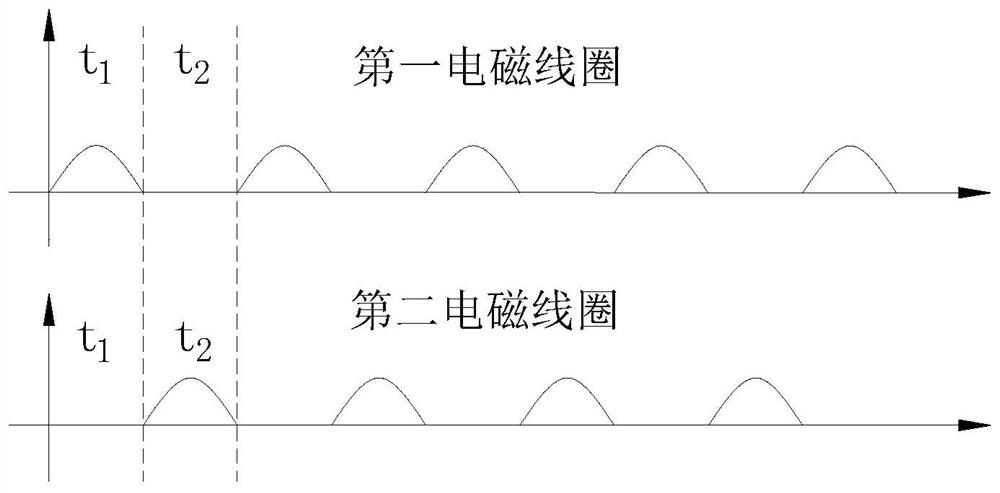

[0078] The first electromagnetic coil and the second electromagnetic coil: both are electromagnetic coils with an inner diameter of 10 mm and an outer diameter of 100 mm.

[0079] The steps of the chemical mechanical polishing adopted in the present embodiment are as follows:

[0080] (1) 0.7% by weight percent of Fe modified by trisodium citrate 3 o ...

Embodiment 2

[0086] The experimental materials used in this embodiment are as follows:

[0087] Ferromagnetic particles: Fe modified with trisodium citrate produced by Zhongke Leiming (Beijing) Technology Co., Ltd. 3 o 4 Microspheres (average diameter 30nm);

[0088] Polishing liquid: Polishing liquid with high selectivity ratio silicon rough polishing produced by Anji Microelectronics Technology (Shanghai) Co., Ltd.;

[0089] Substrate: a single crystal silicon wafer with a diameter of 25.4mm and a surface roughness of 0.5μm;

[0090] Substrate carrier: made of ABS engineering plastics, with a diameter of 100mm and a thickness of 8mm;

[0091] The first electromagnetic coil and the second electromagnetic coil: both are electromagnetic coils with an inner diameter of 10 mm and an outer diameter of 100 mm.

[0092] The steps of the chemical mechanical polishing adopted in the present embodiment are as follows:

[0093] (1) 1.0% by weight of Fe modified by trisodium citrate 3 o 4 Magn...

Embodiment 3

[0099] The experimental materials used in this embodiment are as follows:

[0100] Ferromagnetic particles: nano-nickel powder (average diameter 40nm) from Shanghai Chaowei Nano Technology Co., Ltd.;

[0101] Polishing liquid: adopt the self-made high pH stability polishing liquid of the present invention, its component comprises the pH buffer solution that abrasive silicon dioxide, oxidizing agent ammonium dichromate, sodium carbonate and sodium bicarbonate form.

[0102] Substrate: a single crystal indium phosphide sheet with a diameter of 25.4mm and a surface roughness of 300nm;

[0103] Substrate carrier: made of ABS engineering plastics, with a diameter of 100mm and a thickness of 8mm;

[0104] The first electromagnetic coil and the second electromagnetic coil: both are electromagnetic coils with an inner diameter of 10 mm and an outer diameter of 100 mm.

[0105] The steps of the chemical mechanical polishing adopted in the present embodiment are as follows:

[0106] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com