A surface treatment method for austenitic stainless steel corrosion-resistant reinforced parts

A technology of austenitic stainless steel and surface treatment, applied in the direction of solid-state diffusion coating, coating, metal material coating process, etc., can solve the problems of color change, environmental pollution, low pass rate, etc., and achieve polishing precision High, expand the use range, improve the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

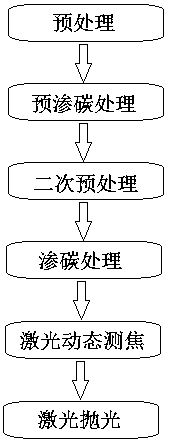

[0032] Such as figure 1 As shown, this embodiment provides a surface treatment method for 304 austenitic stainless steel corrosion-resistant reinforced parts, and the specific process is as follows:

[0033] First, use ultrasonic wave + degreasing agent to remove grease and stains on 304 austenitic stainless steel, dry the surface and put it into a low-pressure atmosphere furnace (about 100Pa); HCl+20%CF 4 Pretreat 304 austenitic stainless steel with mixed gas, keep it warm for 1 hour, fully remove the protective film on the surface of 304 austenitic stainless steel and form Fe chloride on the surface of austenitic stainless steel, which is conducive to carburization; after pretreatment is completed , the low-pressure atmosphere furnace is heated to 490°C for pre-carburizing treatment of 304 austenitic stainless steel, and the carburizing atmosphere is 20%CO+15%H 2 +60%N 2 , with a balance of CO 2, the pre-carburization time is 1h, so that the lower limit area of carbon ...

Embodiment 2

[0036] Such as figure 1 As shown, this embodiment provides a surface treatment method for 316 austenitic stainless steel corrosion-resistant reinforced parts, and the specific process is as follows:

[0037] First, use ultrasonic wave + degreasing agent to remove grease and stains on 316 austenitic stainless steel. After drying the surface, put it into a low-pressure atmosphere furnace (about 1000Pa). %CF 4 Pretreat 316 austenitic stainless steel with mixed gas, keep it warm for 1 hour, fully remove the protective film on the surface of 316 austenitic stainless steel and form Fe chloride on the surface of austenitic stainless steel, which is conducive to the progress of carburization; after the pretreatment is completed , raise the temperature of the low-pressure atmosphere furnace to 500°C to pre-carburize 316 austenitic stainless steel, and the carburizing atmosphere is 20%CO+25%H 2 +45%N 2 , Yu CO 2 , the pre-carburization time is 1h, so that the lower limit area of c...

Embodiment 3

[0040] Such as figure 1 As shown, this embodiment provides a surface treatment method for the corrosion-resistant reinforcement of 201 austenitic stainless steel, and the specific process is as follows:

[0041] First, use ultrasonic wave + degreasing agent to degrease and dry 201 austenitic stainless steel, put it into a low-pressure atmosphere furnace (about 600Pa), raise the temperature of the low-pressure atmosphere furnace to 285°C, and use 80%HCl+20%CF 4 Pretreat 201 austenitic stainless steel with mixed gas, keep it warm for 1 hour, remove the protective film on the surface of 201 austenitic stainless steel and form Fe chloride on the surface of austenitic stainless steel, which is conducive to carburizing; after pretreatment is completed, The low-pressure atmosphere furnace is heated to 485°C for pre-carburizing treatment of 201 austenitic stainless steel, and the carburizing atmosphere is 30%CO+15%H 2 +50%N 2 , Yu CO 2 , the pre-carburization time is 1h, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com