Mine electric drive explosion-proof rubber wheel transport vehicle

A transport vehicle and electric drive technology, applied in the field of transport vehicles, can solve the problems of air pollution, power loss of internal combustion engine, increase in operating cost, etc., and achieve the effect of low operating cost and ensuring safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to facilitate a further understanding of the structure and achieved effects of the present invention, preferred embodiments are described in detail below in conjunction with the accompanying drawings.

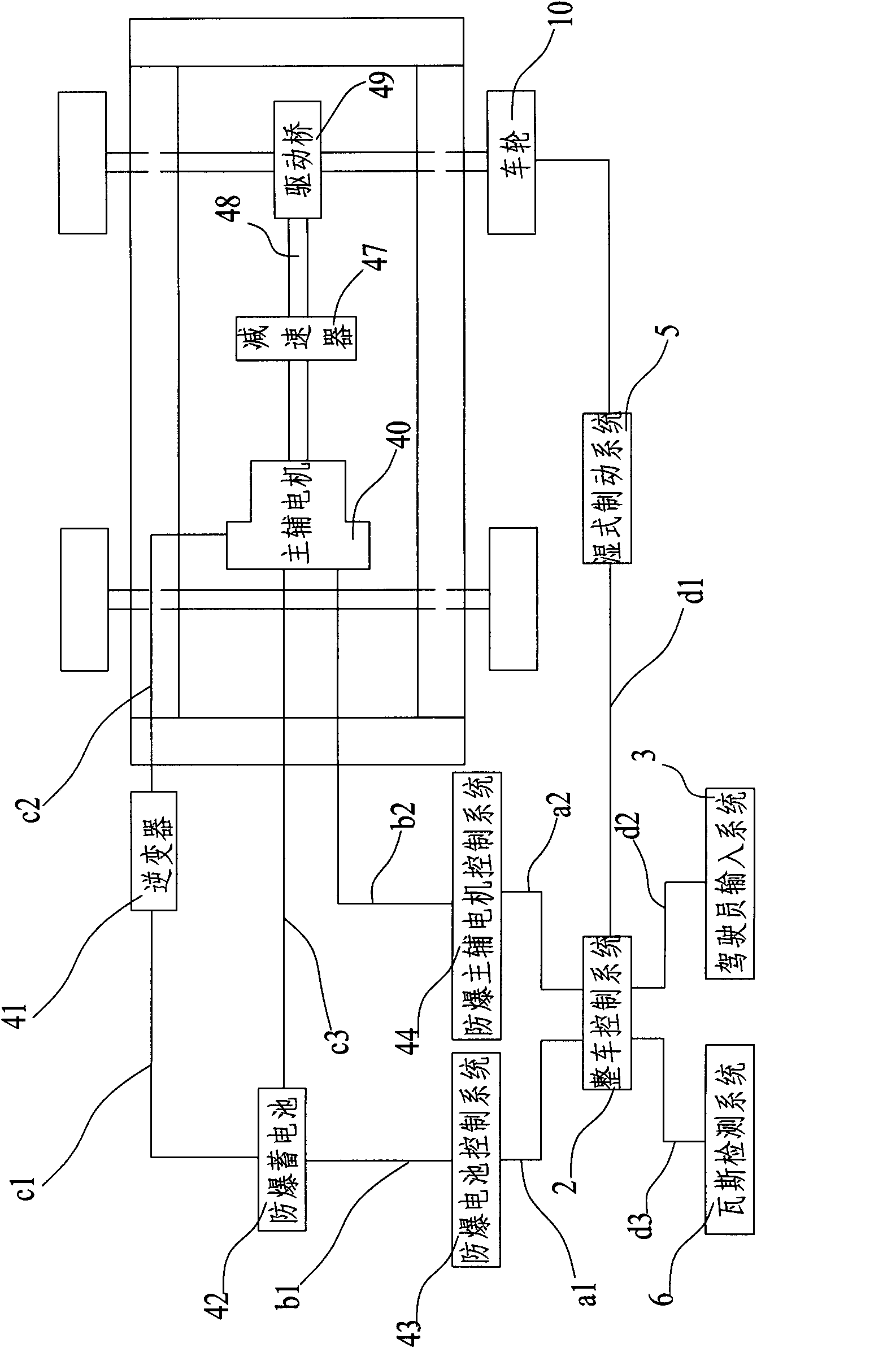

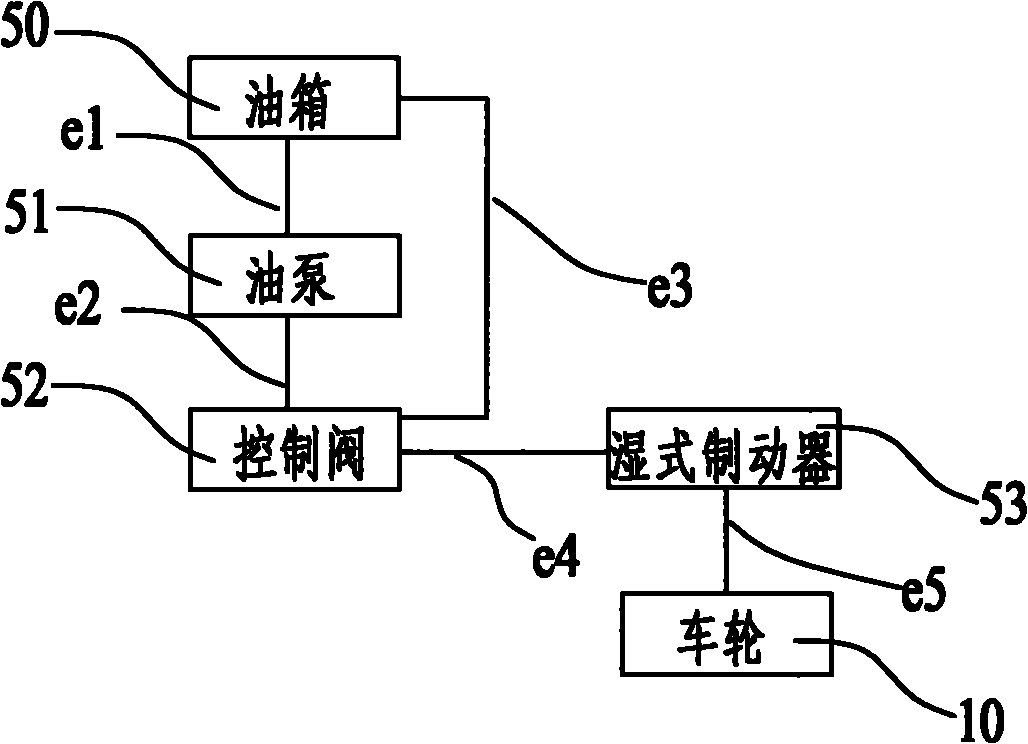

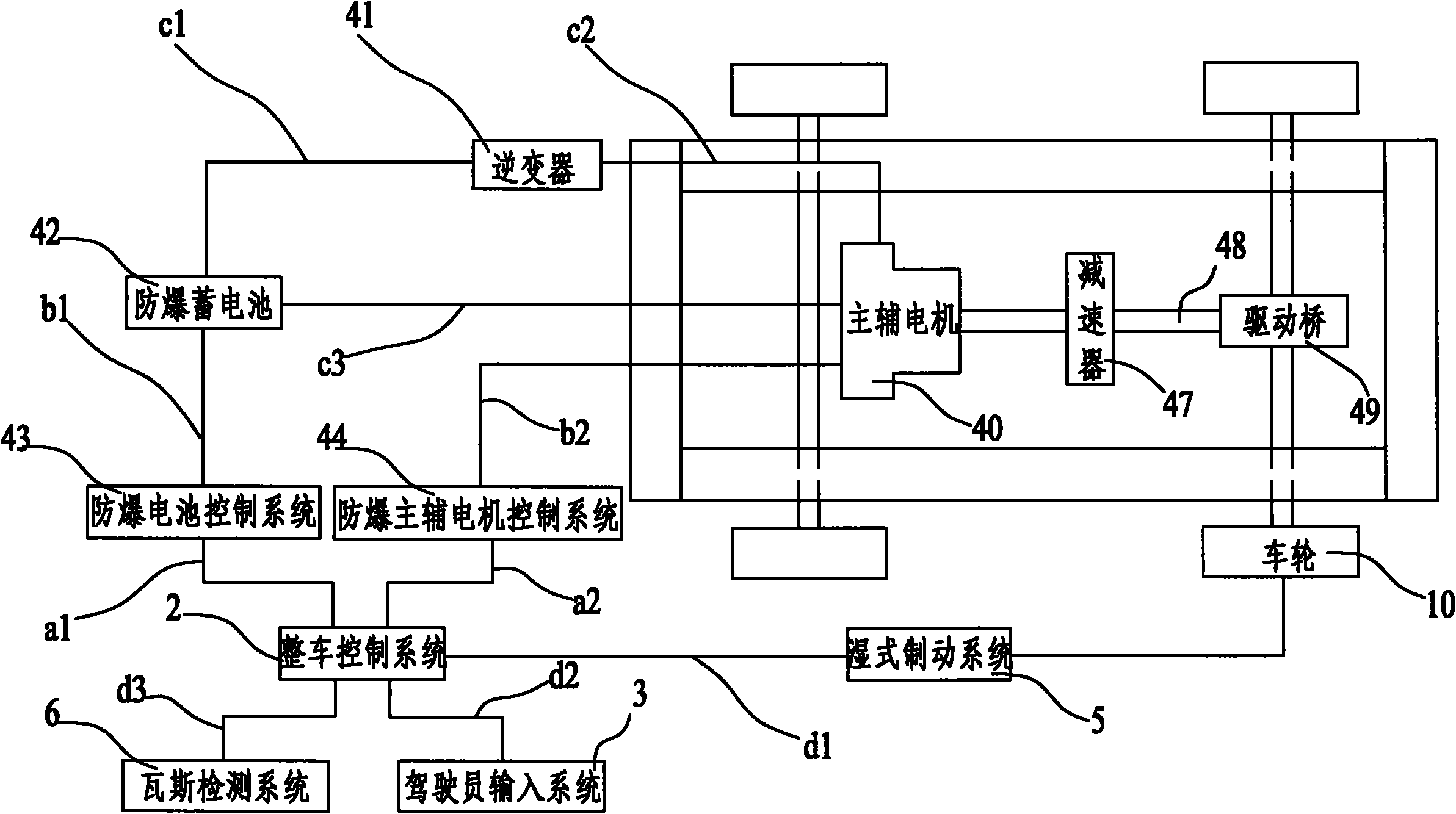

[0015] Such as figure 1 As shown, the mine electric drive explosion-proof rubber-tyred transport vehicle of the present invention includes a vehicle control system 2 arranged on the transport vehicle, a driver input system 3, an explosion-proof electric drive power unit for driving the transport vehicle, and the transport vehicle. The wet braking system 5 for braking the vehicle, and the vehicle control system 2 are respectively connected to the explosion-proof electric drive power unit, the wet braking system 5 and the driver input system 3 through the data bus.

[0016] The explosion-proof electric drive power unit includes a drive unit and a transmission unit connected to the drive unit, wherein the drive unit includes a main and auxiliary motor 40, an invert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com