A continuous production system for phosphorus oxychloride

A technology for connecting and producing phosphorus oxychloride, applied in the direction of phosphorus halide/oxyhalide and the like, can solve the problems of high unit consumption of phosphorus oxychloride, unfavorable long-term use, waste of manpower, etc., and achieves simple equipment composition and less labor. , the effect of reducing unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

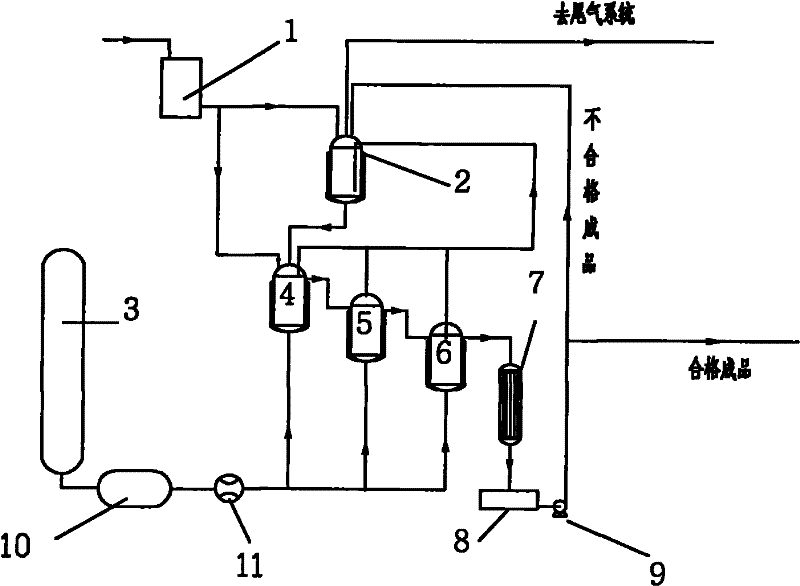

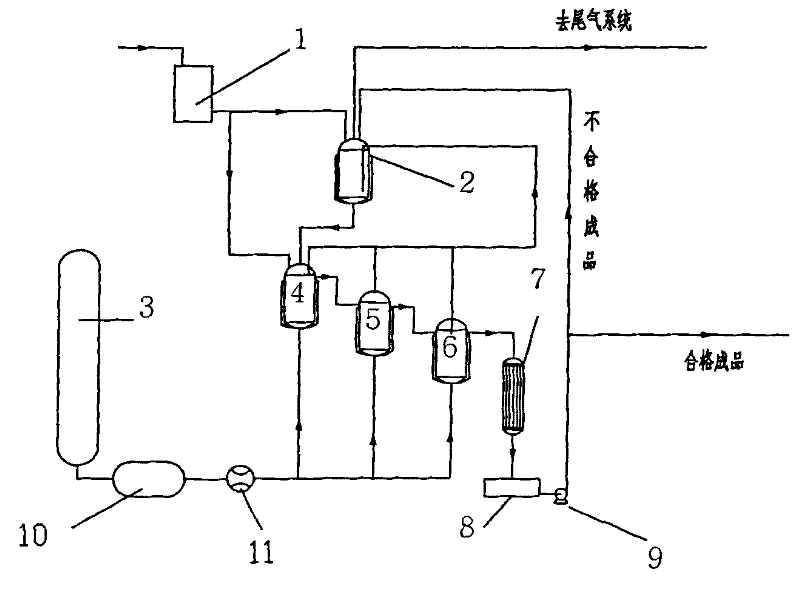

[0015] A continuous production system for phosphorus oxychloride, the system includes a phosphorus trichloride head tank 1, a head reactor 2, an oxygen tank 3, a first-stage reactor 4, a second-stage reactor 5, a third-stage reactor 6, a cooling device 7, finished product tank 8 and finished product pump 9, the outlet of phosphorus trichloride elevated tank 1 is connected with the phosphorus trichloride inlet of elevated reactor 2 and the phosphorus trichloride inlet of primary reactor 4 respectively, one The mixed material inlet on the top of the first-stage reactor 4 is connected with the discharge port of the elevated reactor 2, the discharge port of the first-stage reactor 4 is connected with the feed port of the secondary reactor 5, and the discharge port of the secondary reactor 5 is connected with the feed port of the secondary reactor 5. The 6 feeding ports of the three-stage reactor link to each other, the discharge port of the three-stage reactor 6 links to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com