A kind of preparation method and equipment of high-strength polyester mother silk

A high-strength, mother-filament technology, which is applied in the production of man-made yarn complete sets of equipment, drawing spinning, filament/thread forming, etc. The oil is uniform, the oiling rate is uniform, and the uniformity is guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

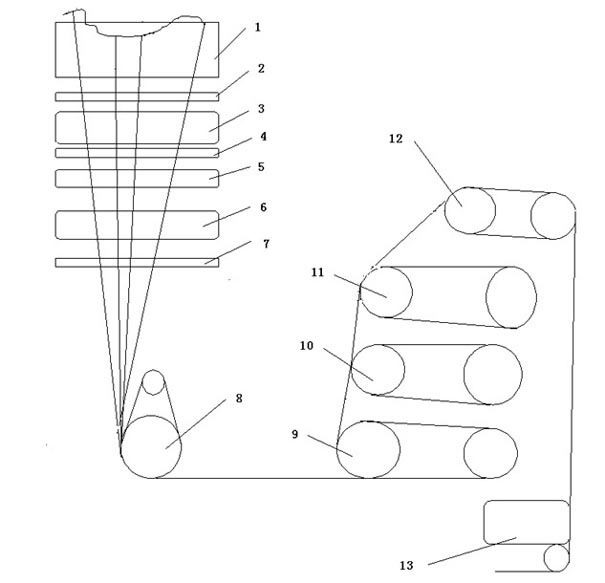

[0016] See attached figure 1 , which is a production process flow chart of a high-strength polyester mother silk provided in this embodiment; the tow coming out of the spinning box assembly is cooled by side blowing and passes through the spinning tunnel 1, and passes through the oiling guide wire hook 2, and the filament The contact length between the tow and the first upper oiler 3 is fixed, and the tow is evenly spread on the first upper oiler through the tension rod 4, and then the active tension regulator 5 adjusts the first tension to the appropriate winding requirement. In this embodiment, after the tension adjustment device 5, the first tension of the tow is controlled at 40-80cN, and the tow after the tension adjustment is adjusted and oiled through the second oiler 6, the purpose is to solve the The monofilament fineness is thick, and the oil film cannot completely wrap the tow evenly in one oiling; after the tow passes through the guide rod 7, it reaches the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com