Preparation method of hyaluronic acid and chitosan composite polyelectrolyte nanofibers

A composite polyelectrolyte, composite nanofiber technology, applied in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of material properties and adverse effects of application, and achieve good biocompatibility and cell adhesion rate, The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

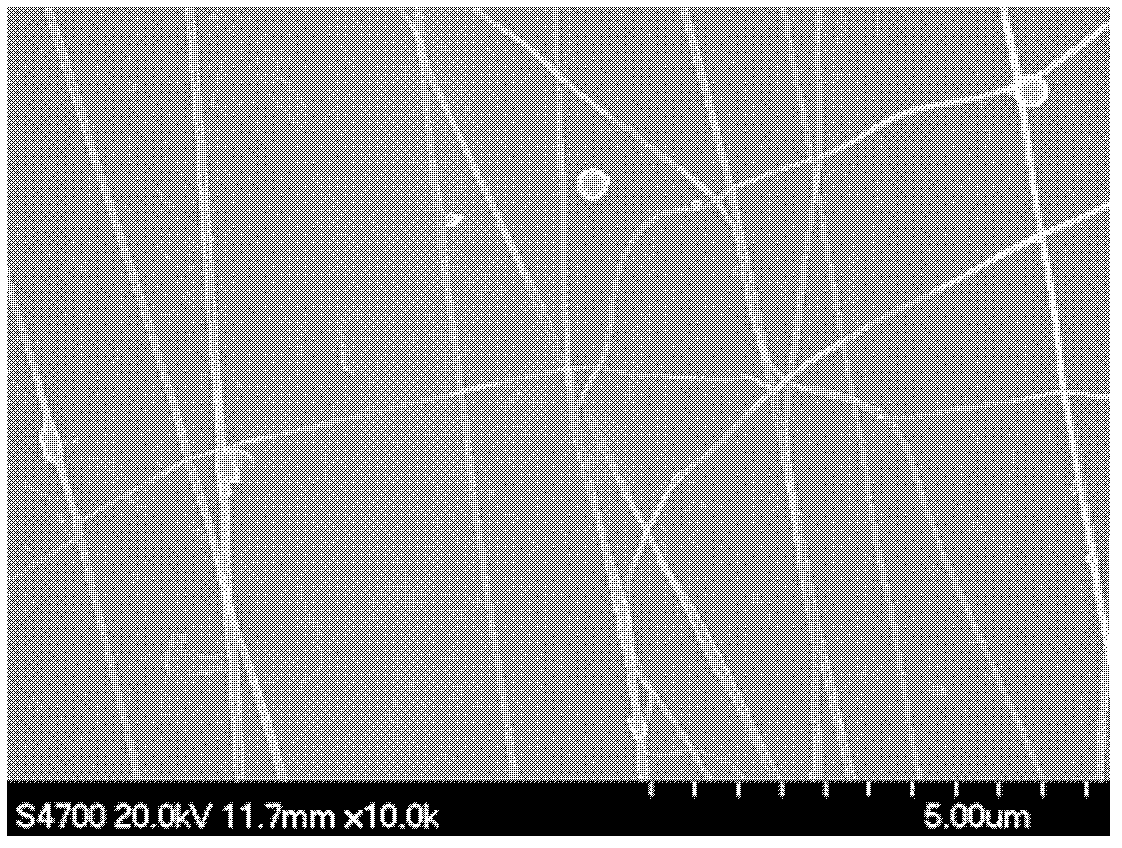

Embodiment 1

[0028] 1) Prepare a mixed solvent of deionized water and formic acid with a mass ratio of 25:75, and hyaluronic acid (Mw= 1 000 000 g mol -1 ) directly dissolved in the solvent, stirred at room temperature until the solution was transparent to make a 1wt% hyaluronic acid solution;

[0029] 2) Chitosan (Mw= 200 000 g·mol -1 ) was dissolved in a mixed solvent of deionized water and formic acid with a mass ratio of 30:70 to prepare a chitosan solution with a concentration of 6wt%;

[0030] 3) Mix the chitosan solution in step 2 and the hyaluronic acid solution in step 1 at a volume ratio of 1:9, and stir for 3 hours to obtain a uniform electrospinning solution;

[0031] 4) Put the electrospinning solution in step 3 into a 5ml syringe, set the extrusion speed to 0.1ml / h; the spinning voltage is 20kV, the distance from the spinning nozzle to the receiver is 15cm, start spinning, and that’s it Obtain the natural polymer nanofibers with pH-adjustable chargeability.

[0032] After ...

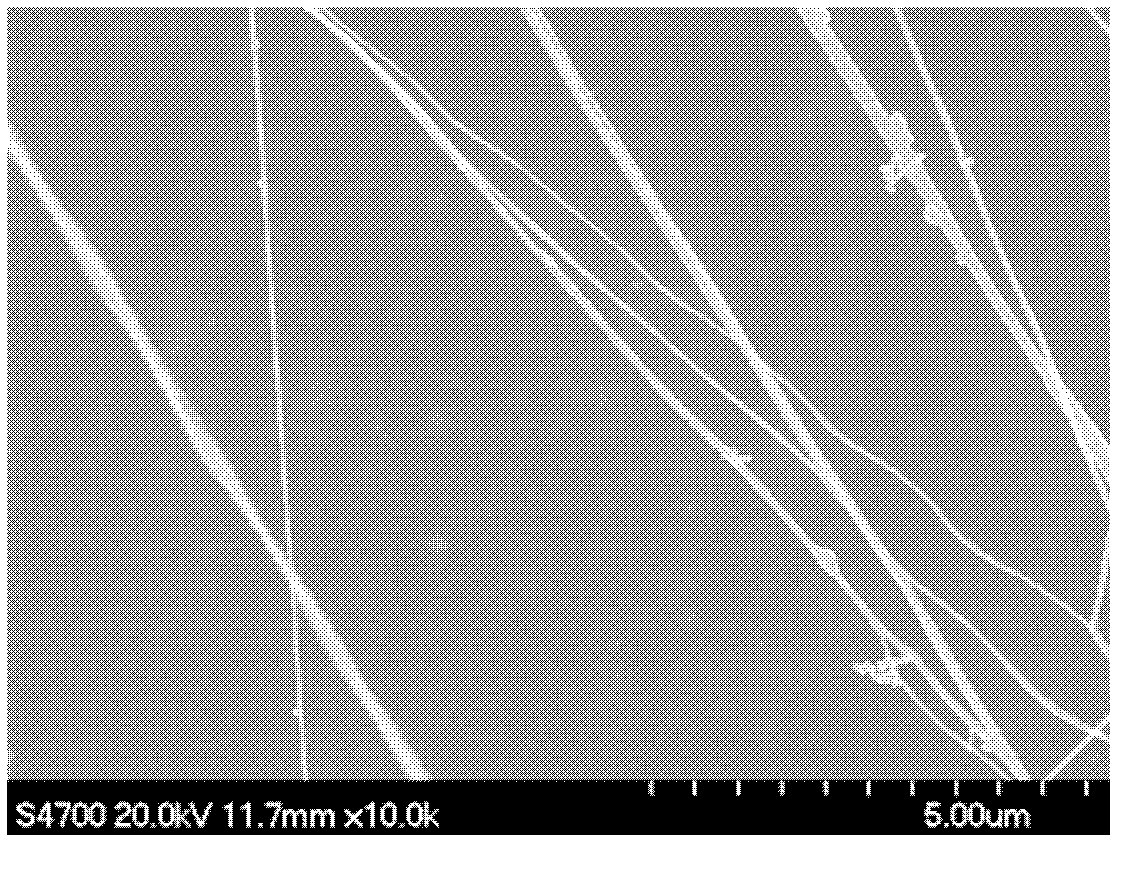

Embodiment 2

[0035] 1) Prepare a mixed solvent of deionized water and formic acid with a mass ratio of 30:70, and hyaluronic acid (Mw= 1 000 000 g mol -1 ) directly dissolved in the solvent, stirred at room temperature until the solution was transparent to make a 1wt% hyaluronic acid solution;

[0036] 2) Chitosan (Mw= 200 000 g·mol -1 ) was dissolved in a mixed solvent of deionized water and formic acid with a mass ratio of 20:80 to prepare a chitosan solution with a concentration of 6wt%;

[0037] 3) Mix the chitosan solution in step 2 and the hyaluronic acid solution in step 1 at a volume ratio of 1:9, and stir for 3 hours to obtain a uniform electrospinning solution;

[0038] 4) Put the electrospinning solution in step 3 into a 5ml syringe, set the extrusion speed to 0.1ml / h; the spinning voltage is 20kV, the distance from the spinning nozzle to the receiver is 15cm, start spinning, and that’s it Obtain the natural polymer nanofibers with pH-adjustable chargeability.

[0039]

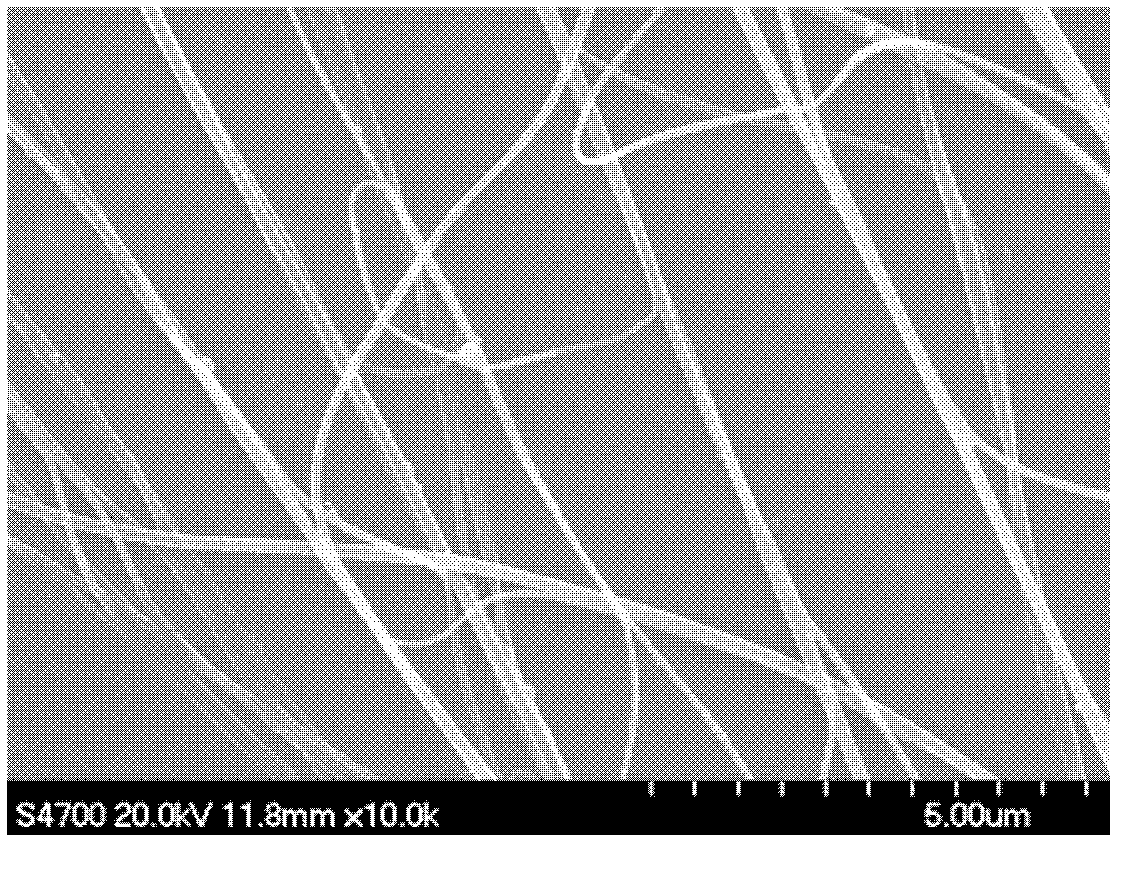

Embodiment 3

[0041] 1) Prepare a mixed solvent of deionized water and formic acid with a mass ratio of 50:50, and hyaluronic acid (Mw= 1 000 000 g mol -1 ) directly dissolved in the solvent, stirred at room temperature until the solution was transparent to make a 1wt% hyaluronic acid solution;

[0042]2) Dissolve chitosan (Mw=200 000 g mol-1) in a mixed solvent of deionized water and formic acid with a mass ratio of 10:90 to prepare a chitosan solution with a concentration of 6wt%;

[0043] 3) Mix the chitosan solution in step 2 and the hyaluronic acid solution in step 1 at a volume ratio of 1:9, and stir for 3 hours to obtain a uniform electrospinning solution;

[0044] 4) Put the electrospinning solution in step 3 into a 5ml syringe, set the extrusion speed to 0.1ml / h; the spinning voltage is 20kV, the distance from the spinning nozzle to the receiver is 15cm, start spinning, and that’s it Obtain the natural polymer nanofibers with pH-adjustable chargeability.

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap