Method of measuring moment of inertia of washing machine drum and washing machine implementing the method

A technology of a washing machine drum and a measuring method, which is applied to the control device of washing machines, other washing machines, washing devices, etc., can solve problems such as inaccurate measurement, and achieve the effects of reducing calculation costs, eliminating measurement errors, and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

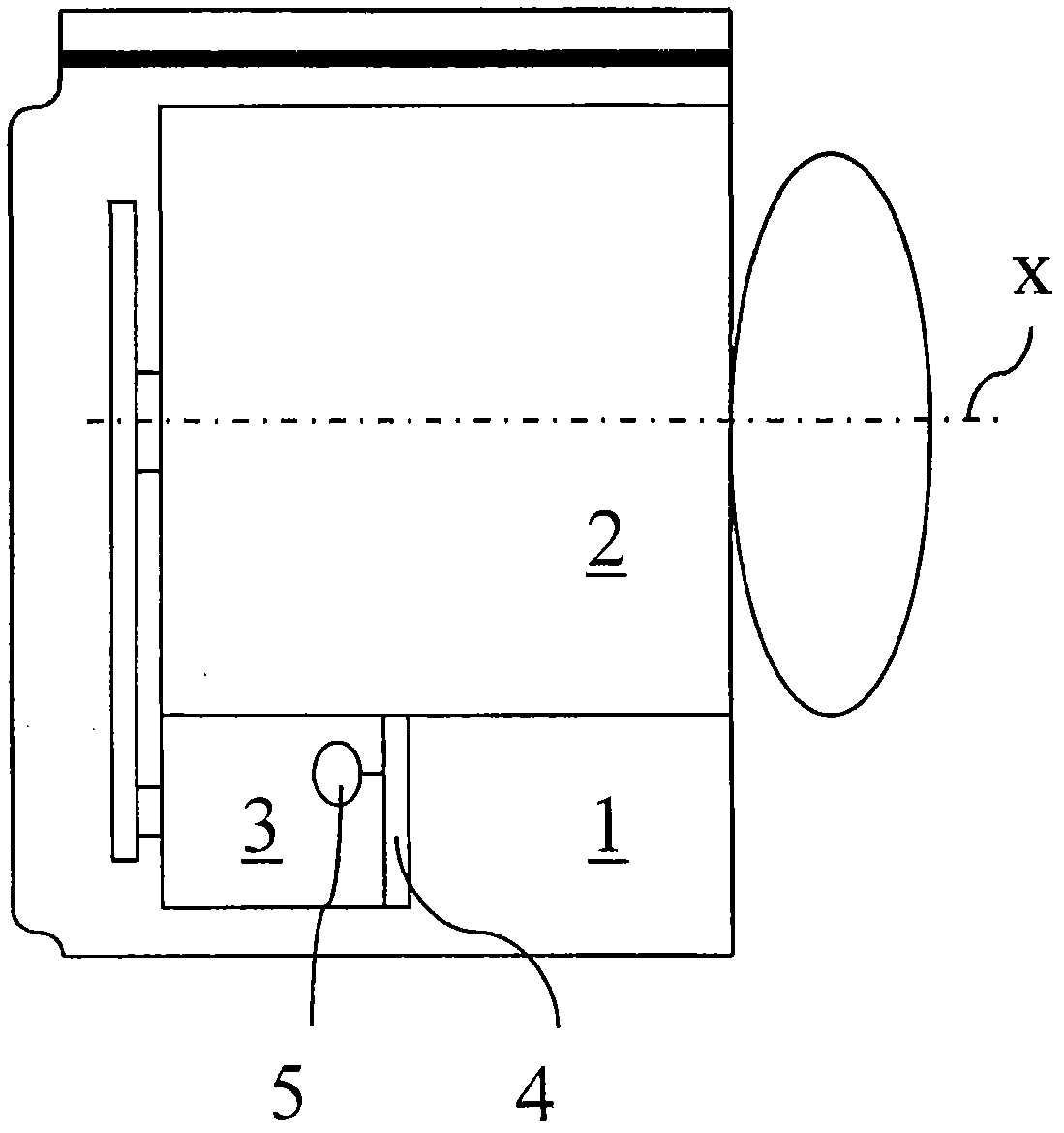

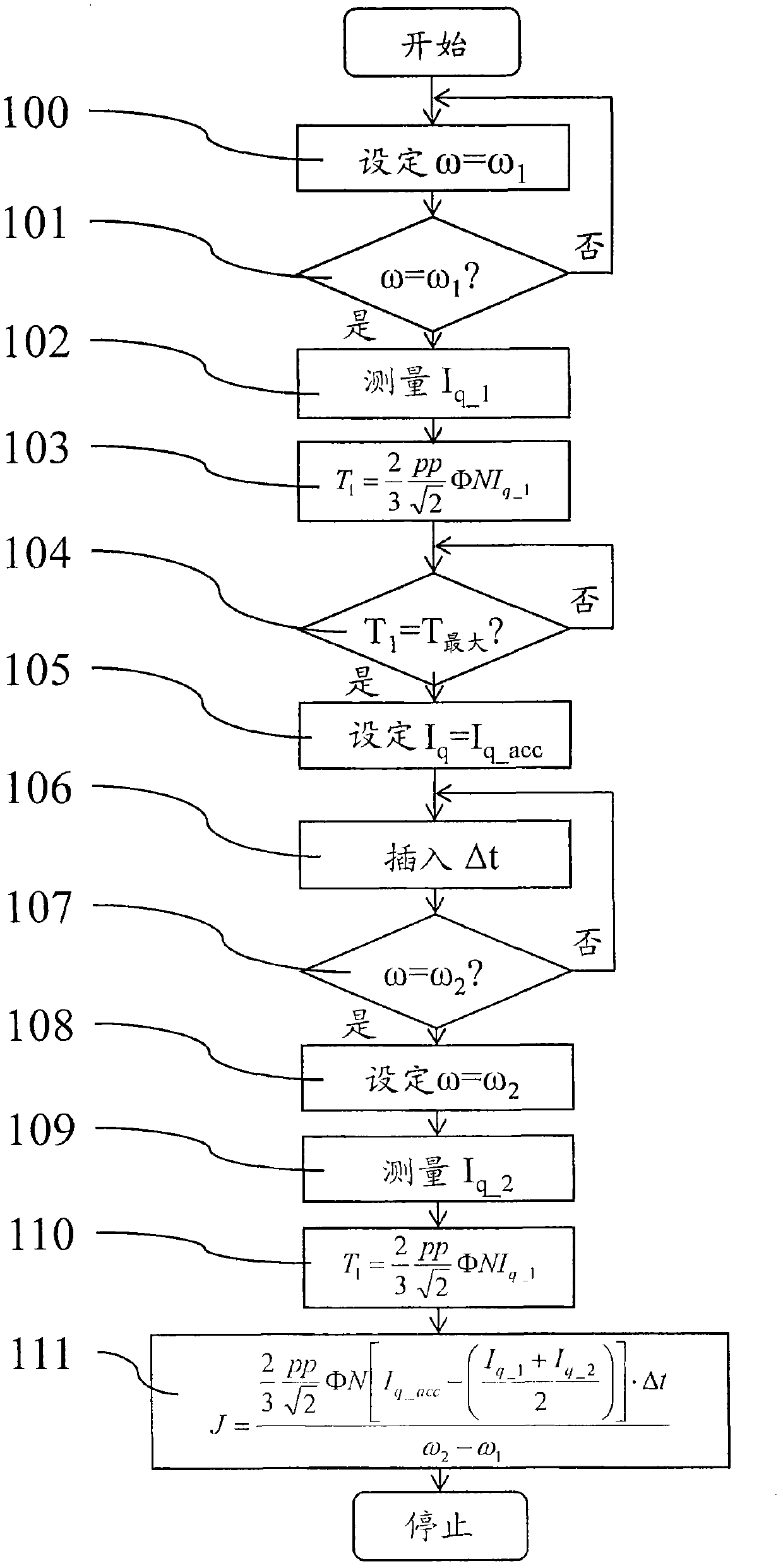

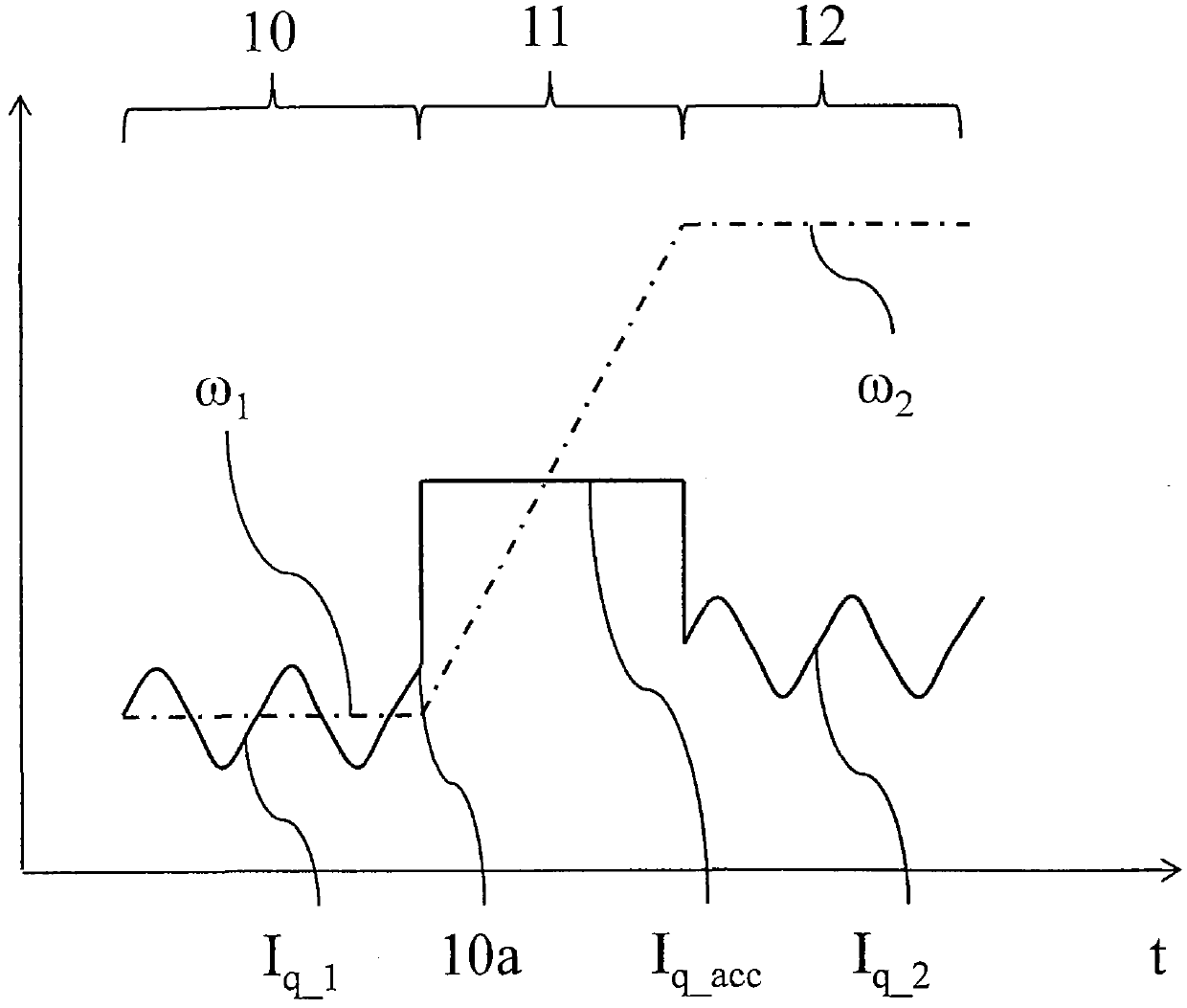

[0051] Reference attached figure 1 , a washing machine generally indicated at 1 comprises a drum 2 mounted in a drum housing according to a horizontal axis of rotation x and a synchronous motor 3 arranged for moving the drum 2 about the axis of rotation x.

[0052] The drum 2 is arranged to receive laundry or other items to be washed therein; in the remainder of this description, the term load will be used to refer generally to the contents of this drum.

[0053] In particular, the synchronous motor 3 is of the permanent magnet type and the outer cup rotor is connected in a known manner by a drive belt to the previously mentioned rotating drum 2 .

[0054] The synchronous motor 3 is associated with a control unit 4 comprising a motor drive circuit whose purpose is to implement the method for measuring the moment of inertia described below. The control unit 4 is connected to a Hall effect sensor 5 for measuring the angular velocity of the synchronous motor 3 .

[0055] Before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com