Method for calendaring aramid fiber insulation paper

An insulating paper and aramid fiber technology, which is applied in the calendering field of aramid insulating paper, can solve the problems of poor surface smoothness and whiteness, rough surface of aramid insulating paper, unstable dielectric properties, etc., and achieves the improvement of crystallinity. , Uniform dielectric properties, good smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

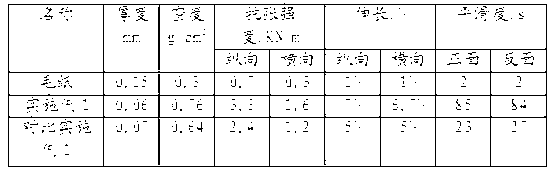

Image

Examples

Embodiment 1

[0030] Raw materials: meta-aramid chopped fiber, denier 2D, length 6mm, the percentage content of meta-aramid chopped fiber in wool paper is 30%; meta-aramid pulp, percussion degree 35, length 2-8mm, wool paper The percentage of aramid pulp in the middle of the paper is 70%, the pulping concentration is 10%, the pulping time is 1h, the online concentration is 0.5%, the pulp-to-net ratio is 1.08, the paper machine speed is 50m / min, the wool paper The drying temperature in the production stage is 120°C.

[0031] A calendering method for aramid insulating paper, the calendering method comprising the following steps in sequence:

[0032] (1) Pre-calender the wool paper at a temperature of 130°C and a pressure of 6MPa;

[0033] (2) Carry out high-temperature calendering on wool paper at a temperature of 300°C and a pressure of 12 MP;

[0034] (3) Carry out ultra-low temperature calendering on wool paper, the temperature is minus 5 ℃, and the pressure is 5 MPa;

[0035] (4) Carry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com