Wet spray double tube sprayer

A sprayer and wet spraying technology, applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of unsafe, polluted working environment, flying cement, etc., and achieve the effect of high working efficiency and avoiding dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

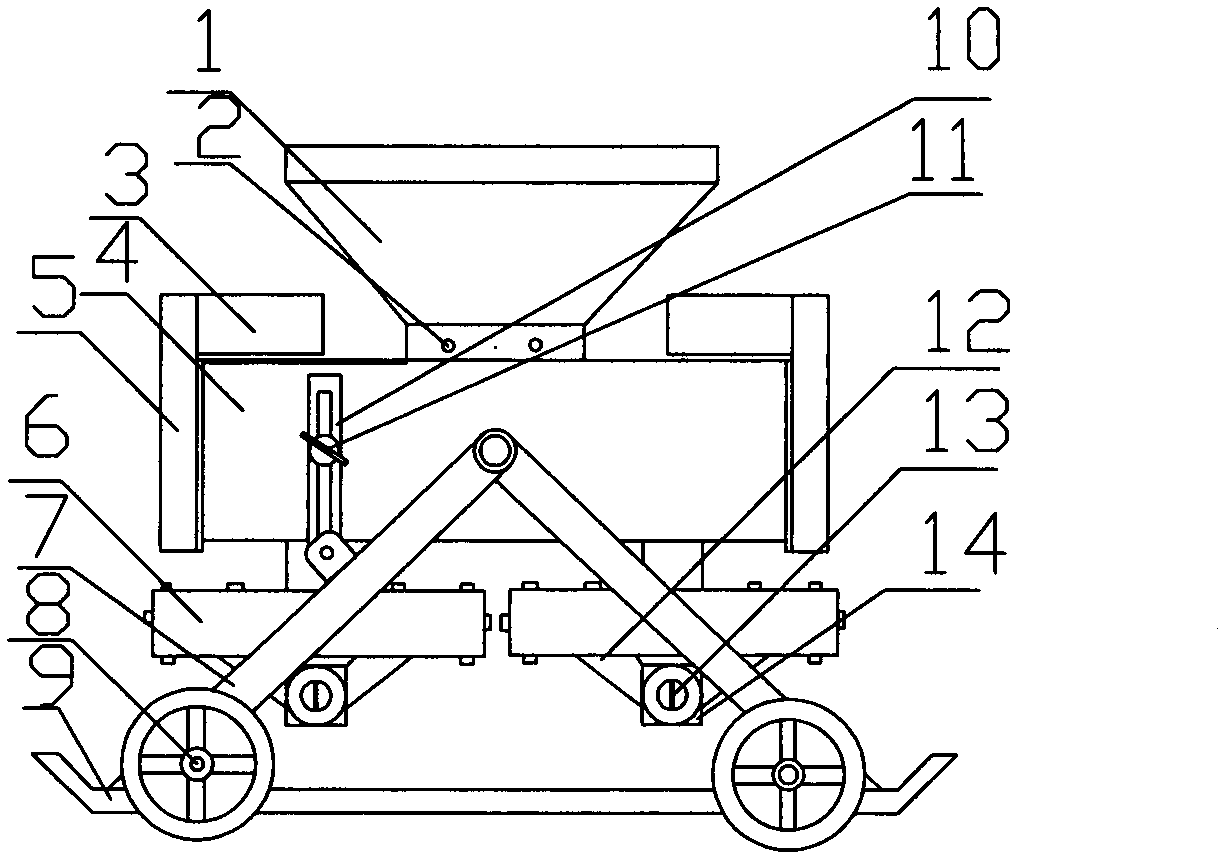

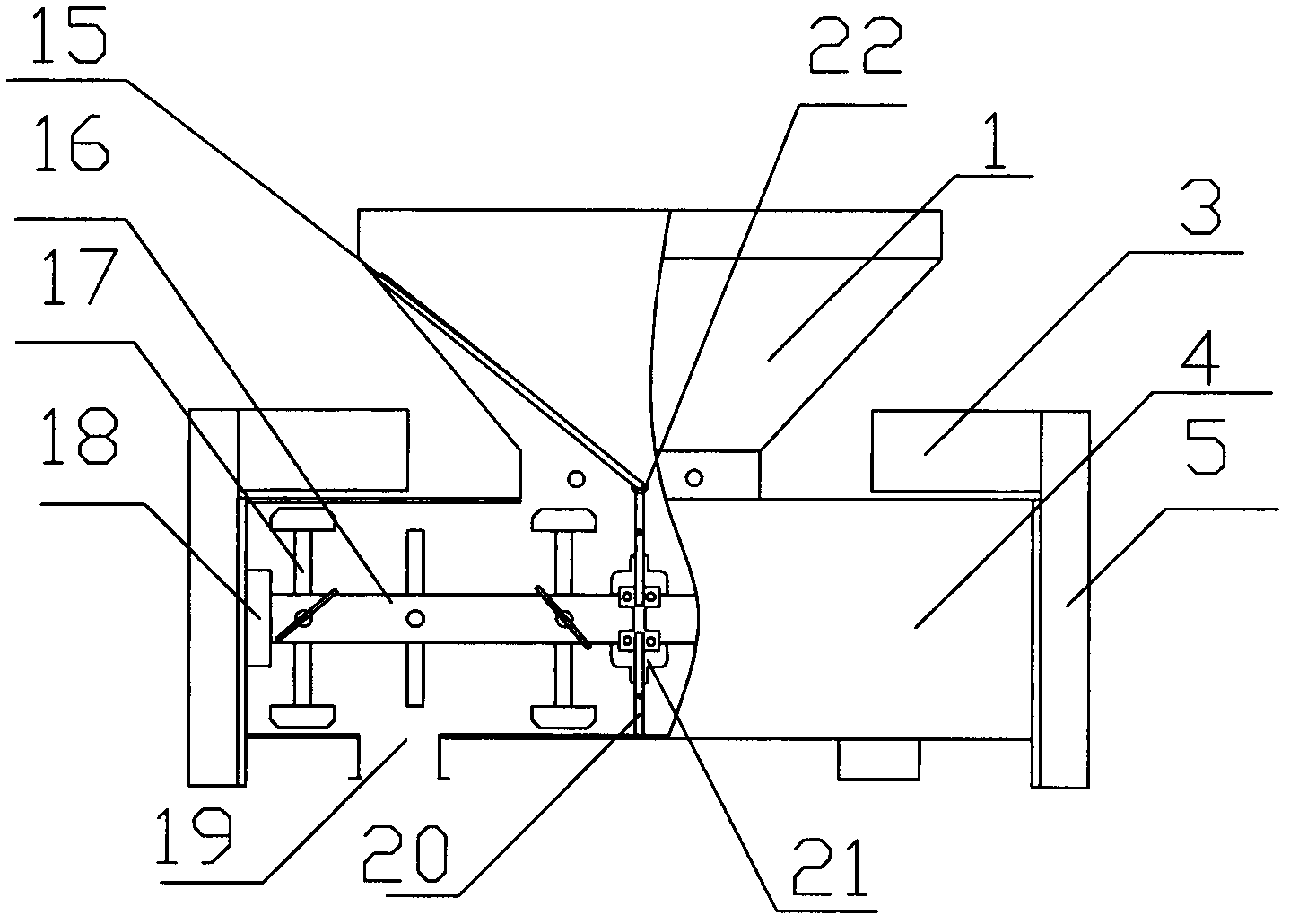

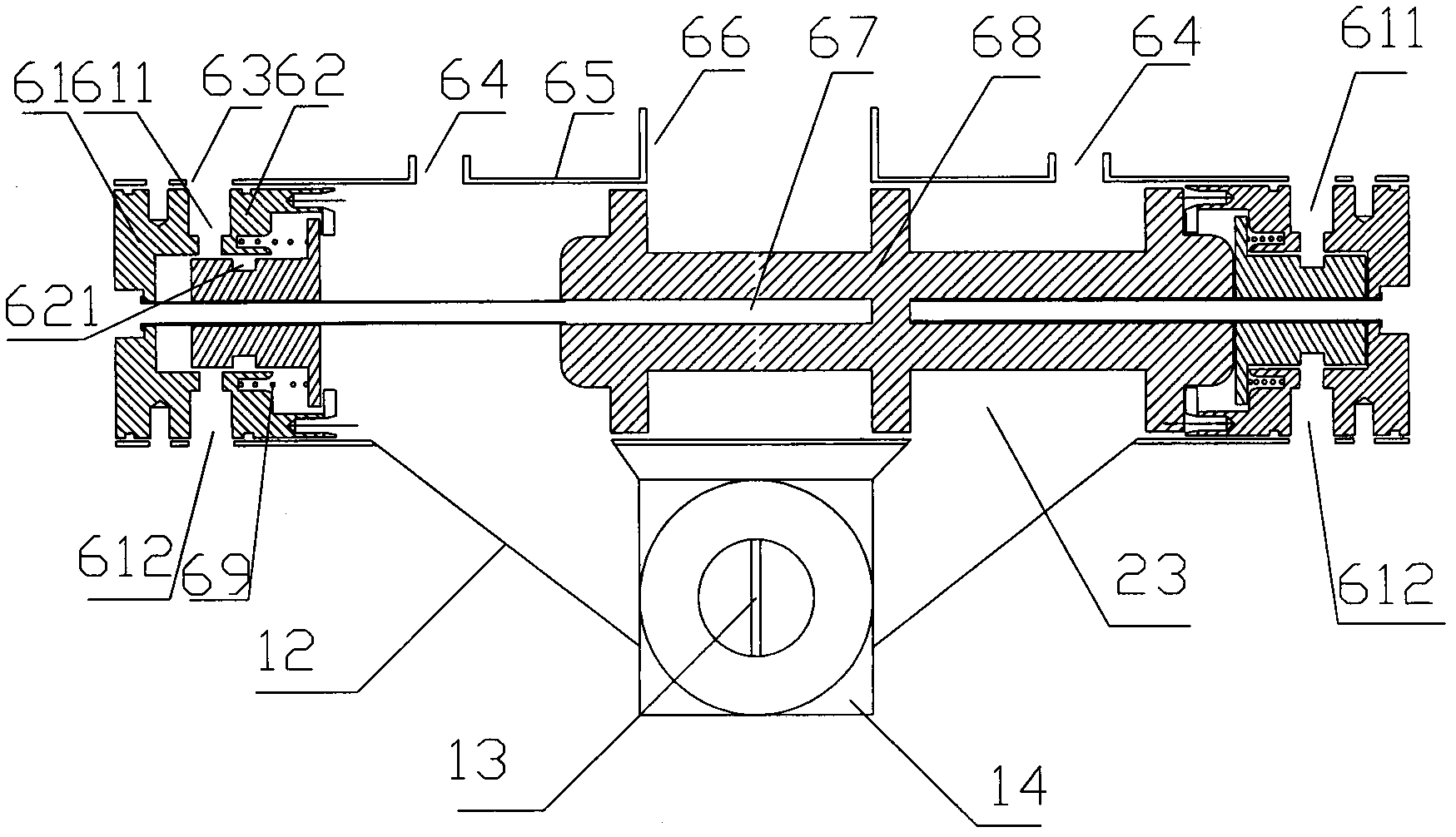

[0012] Such as figure 1 with figure 2 As shown, the wet spray double-tube sprayer has a base 9, a mixing box 4 installed on the base 9, a hopper 1 is installed at the opening of the mixing box 4; a movable baffle 15 is set in the hopper 1, and the shell of the hopper 1 There are multiple water inlets 2; two stirring devices are symmetrically arranged in the stirring box 4, a baffle 20 is installed between the two stirring devices, and the baffle 20 separates the two stirring devices; A reduction box 5 and power equipment 3 are installed at both ends; the bottom ends of both sides of the mixing box 4 are provided with discharging ports 19, and each discharging port is connected to a material cylinder 6, and the bottom ends of both sides of the material cylinder 6 are provided with outlets. The discharge port 23 and the discharge port 23 are connected to a spray head 14 through a pipe; it also includes a hydraulic system for controlling the work of the material cylinder 6. To fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com