High vacuum glass oil diffusion pump

An oil diffusion pump and high vacuum technology, applied in diffusion pumps, pumps, non-displacement pumps, etc., can solve the problems that cannot be well satisfied and the requirements of vacuum pumping degree are getting higher and higher, and can improve the degree of vacuum pumping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

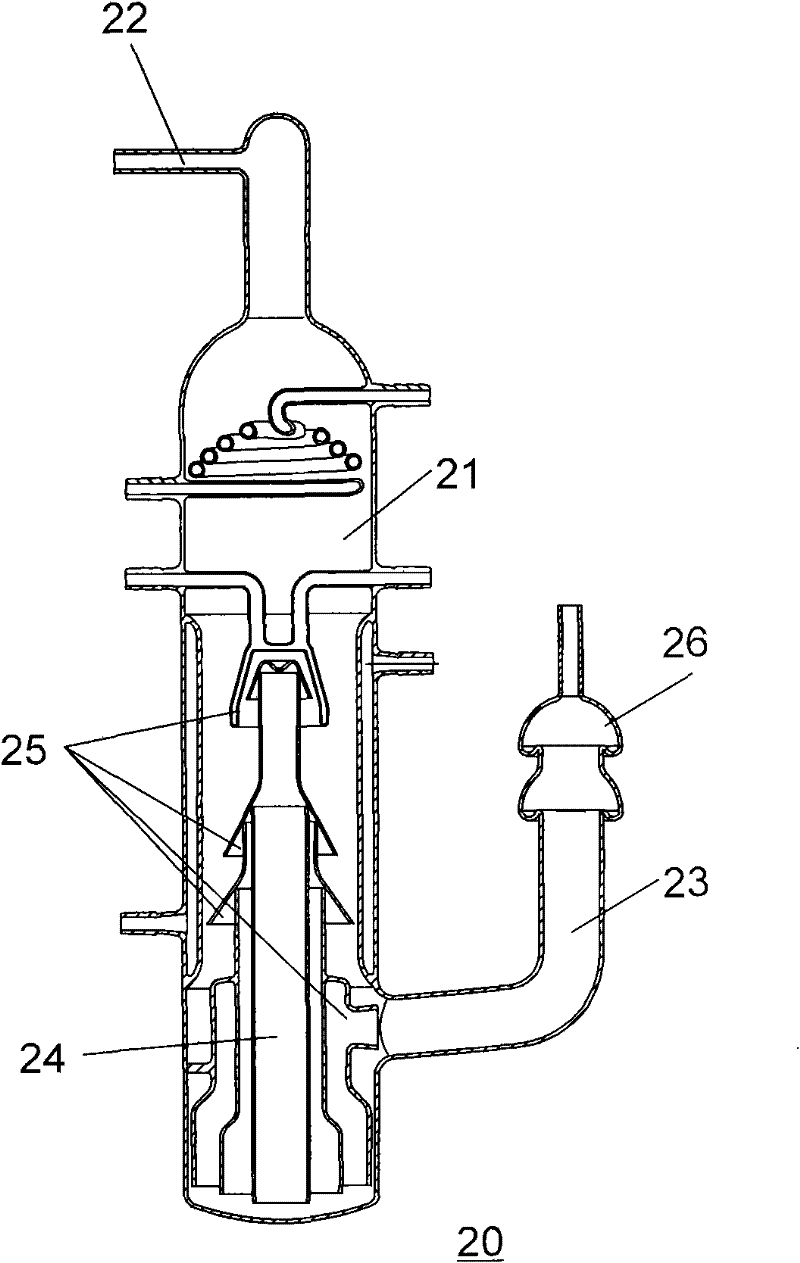

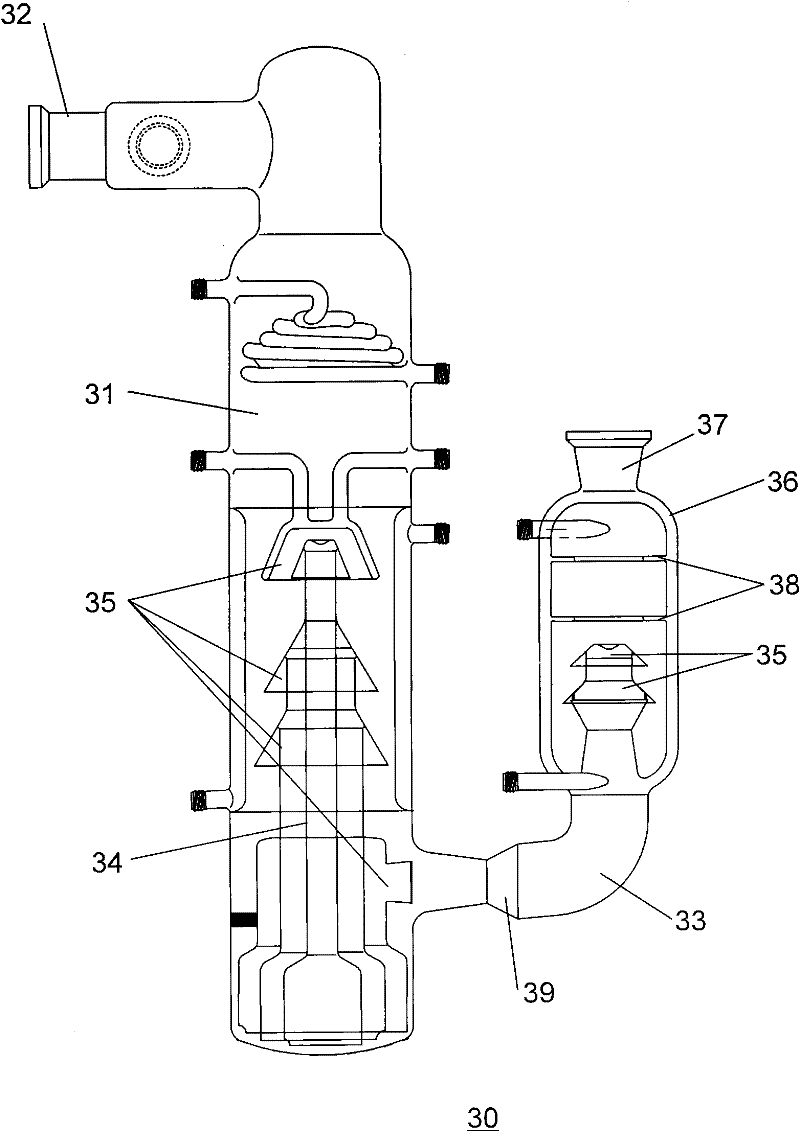

[0017] see image 3 Shown, high vacuum glass oil diffusion pump 30 of the present invention comprises by main pump body 31 and secondary pump body 36, main pump body 31 and four-stage vacuum glass oil diffusion pump 20 of prior art (see figure 2 The structure of the pump body 21 of ) is basically the same, and the upper and lower sides of the main pump body 31 are also connected with the suction pipe 32 and the suction pipe 33 respectively. The first to fourth four-stage nozzles 35 , wherein the fourth-stage nozzle 35 faces the exhaust pipe 33 . The auxiliary pump body 32 is then connected to the other end of the air extraction pipe 33 , and the auxiliary pump body 32 is also provided with several stages of nozzles 35 communicating with the air extraction pipe 33 , and the other end of the auxiliary pump body 32 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com