A conversion device that can realize the drop weight tensile impact test

A technology of tensile impact and conversion device, which is applied in the direction of testing the strength of materials, measuring devices, and instruments using a single impact force, which can solve the problems of unstable test data and achieve the effect of simple structure and stable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

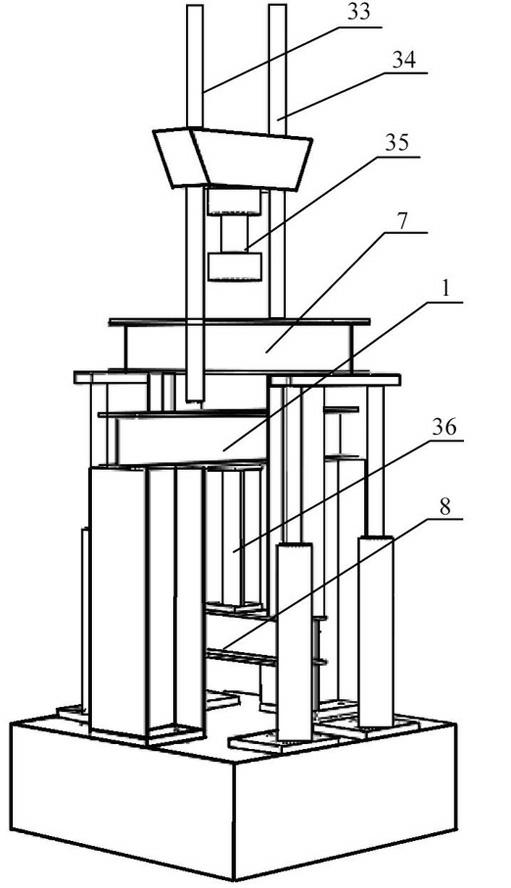

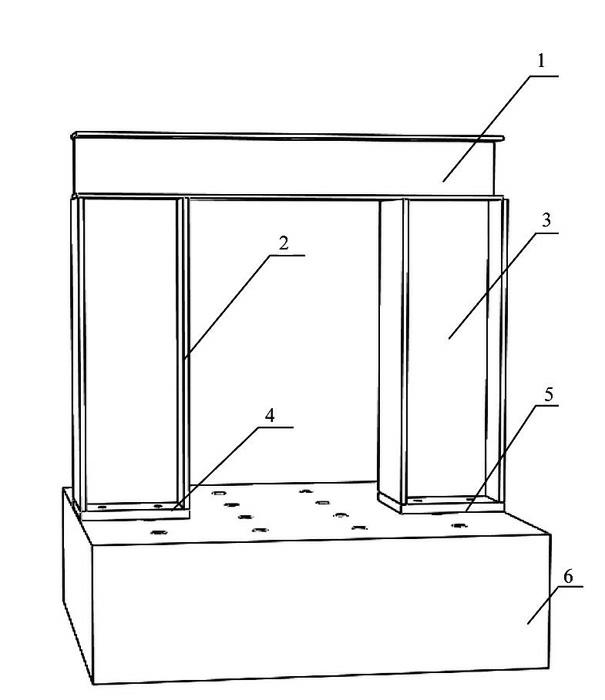

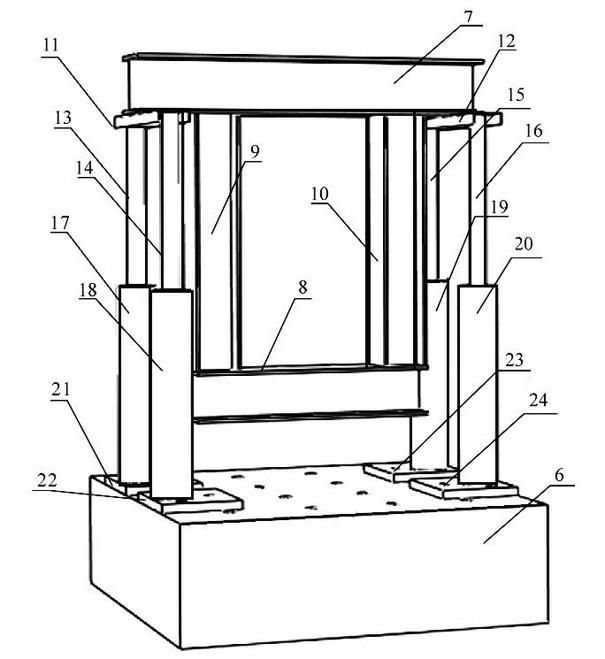

[0031] A conversion device capable of realizing a drop weight tensile impact test is composed of two parts: a fixed beam column frame and a force transmission beam column frame located below the hammer head of a drop weight testing machine. see figure 1 , a fixed beam-column frame such as figure 2 As shown, it is composed of beam 1, columns 2, 3, column end plates 4, 5, and pedestal 6. The two ends of the beam 1 are welded to the upper ends of the columns 2 and 3 respectively, the lower ends of the columns 2 and 3 are welded to the column end plates 4 and 5 respectively, and the column end plates 4 and 5 and the pedestal 6 are fixed with bolts. beam-column frame image 3 and Figure 6 Shown, it consists of upper beam 7, lower beam 8, force transmission column 9,10, force transmission channel steel 11,12, four small round pipes 13,14,15,16, four large round pipes 17,18,19 , 20, four large circular tube end plates 21,22,23,24, eight linear bearings 25,26,27,28,29,30,31,32 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com