SMT method and structure for radiographic detection of pipe welds

A technology of radiographic detection and patching, which is applied in the fields of patching of tube welds, patching structures of radiographic testing, and patching structures of tube welding seams. , Inconvenient positioning and other problems, to achieve the effect of waste utilization, process reduction and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

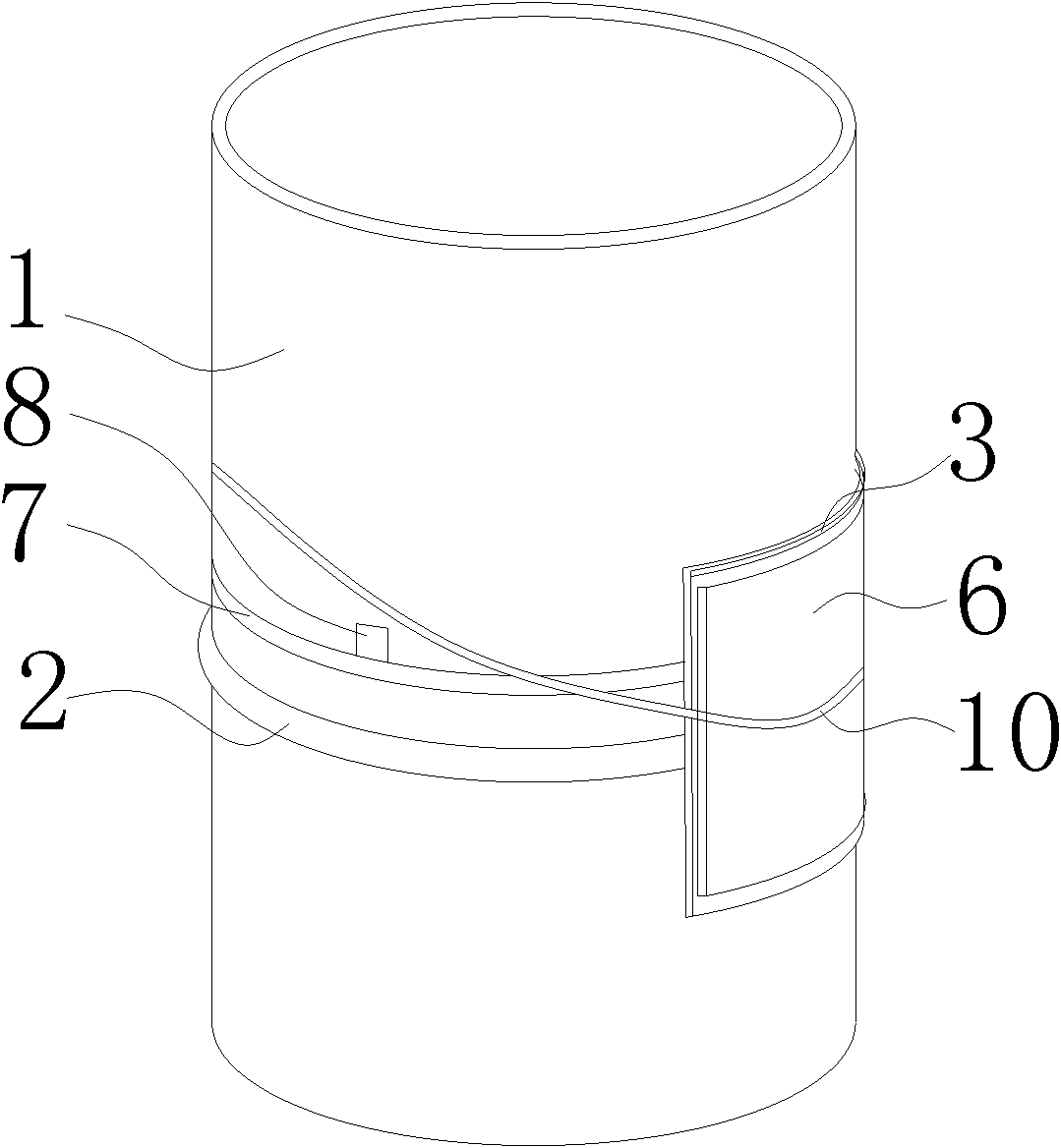

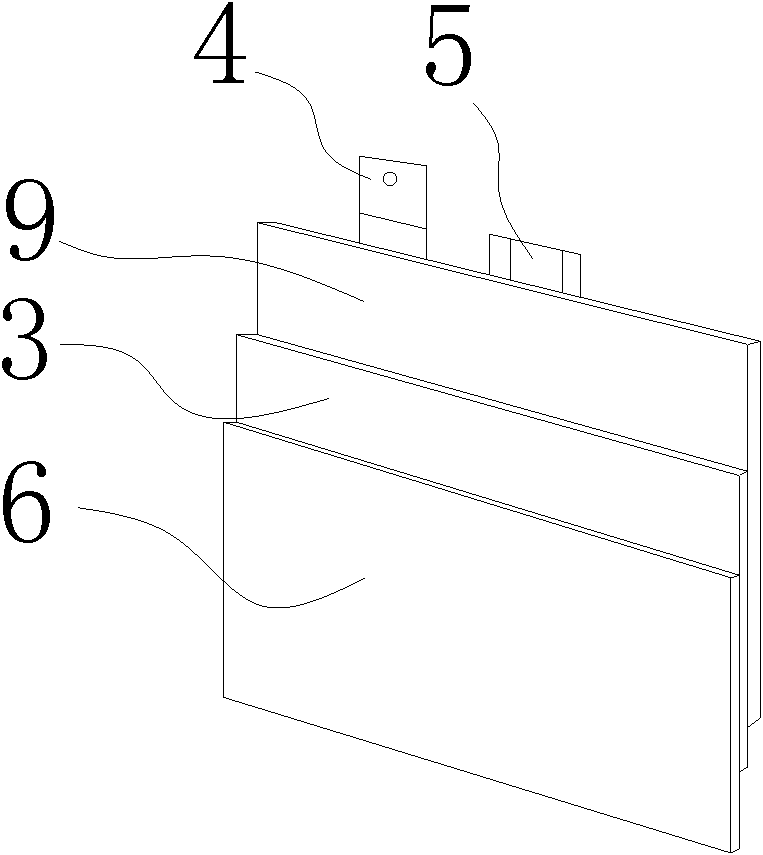

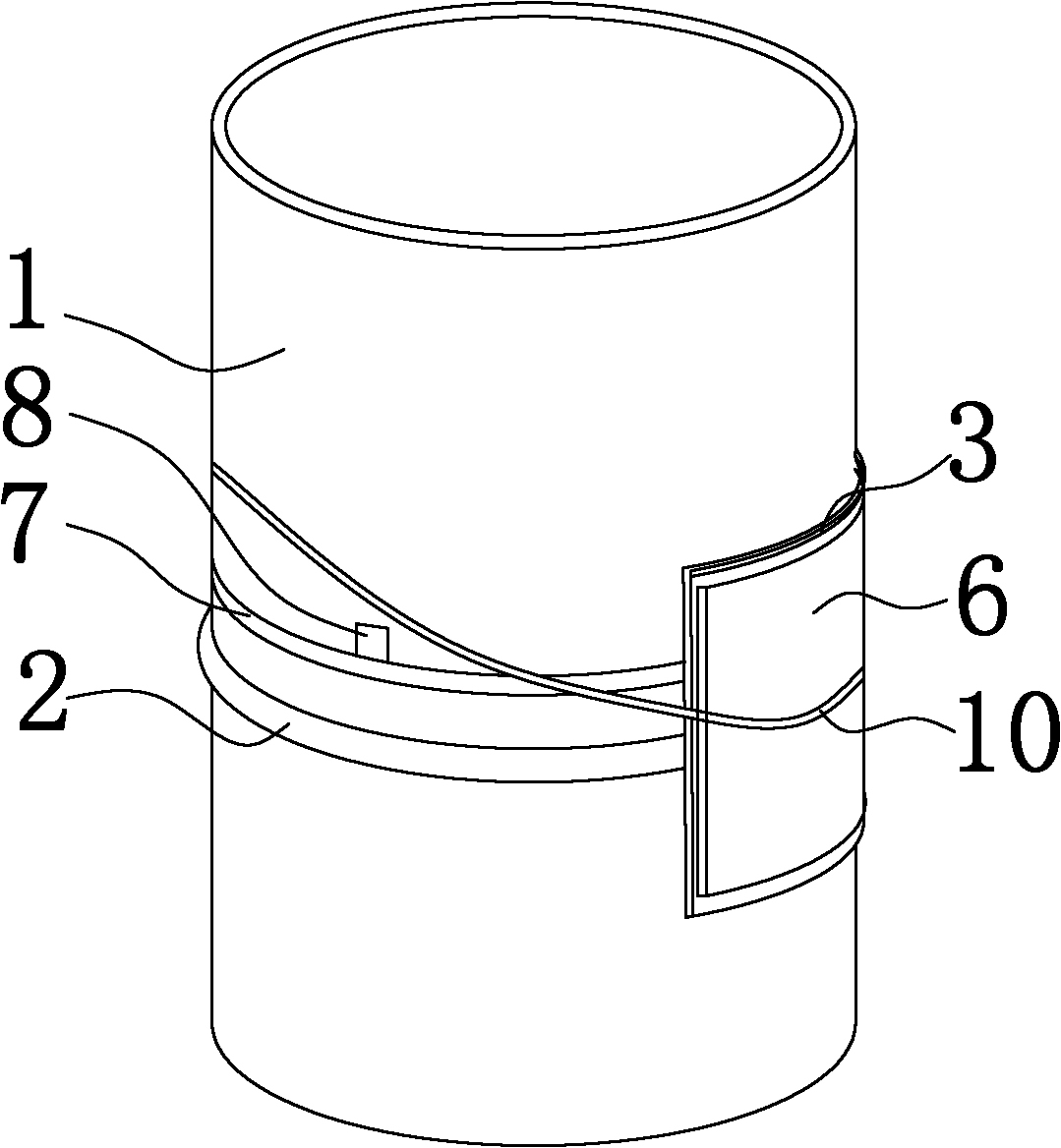

[0037] Taking a pipe butt joint with a diameter of 159mm as an example, if 4 times of transillumination are performed, the effective length of each transmission is about 125mm. Use the following steps to patch:

[0038] A. Make segmented tape 7, put the medical tape on the platform, with the adhesive side facing up, put the lead characters of the numbers 1, 2, 3 and 4 facing up, stick them on the tape at intervals of 125mm, pay attention to the lead characters Need to be exposed to the tape. After the lead type is glued, fold the adhesive tape in half from the end of the No. 4 lead type to the direction of the No. 1 lead type, and make the upper adhesive tape longer than the lower adhesive tape, that is, make the adhesive side of the upper adhesive cloth face downward to expose a section, so as to surround the segmented tape 7 Carry out adhesion when checking steel pipe 1, so just made a subsection band 7.

[0039] B. Fix the segmented tape 7 to the side of the transillumina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com