Amido-functionalized graphene oxide composite material and preparation method and application thereof

A composite material, amine-based function technology, applied in the direction of material electrochemical variables, etc., can solve the problems of poor heavy metal ion capture ability, limited effective contact area, poor electronic conduction, etc. Large-scale industrial production, beneficial effect of enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

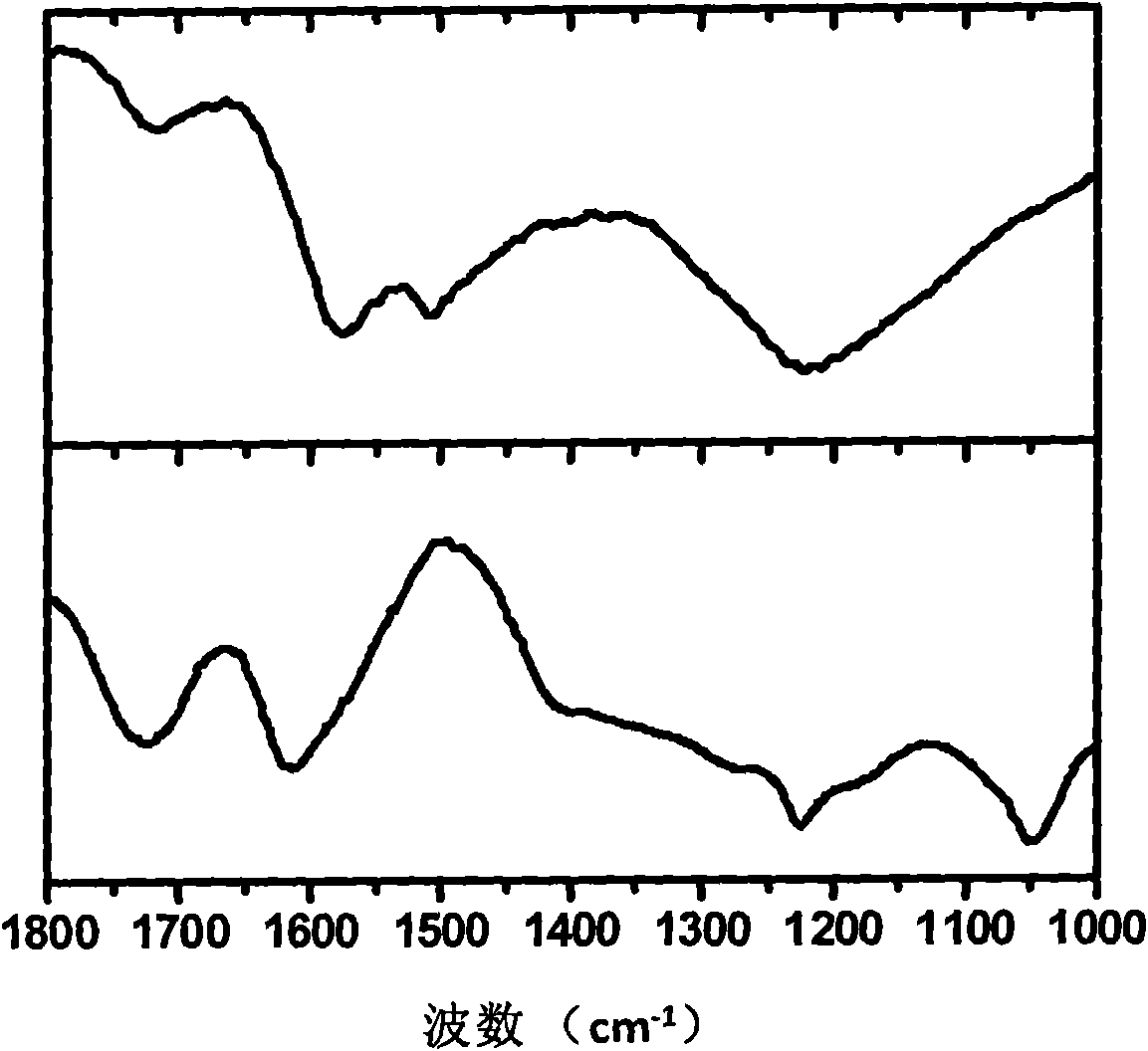

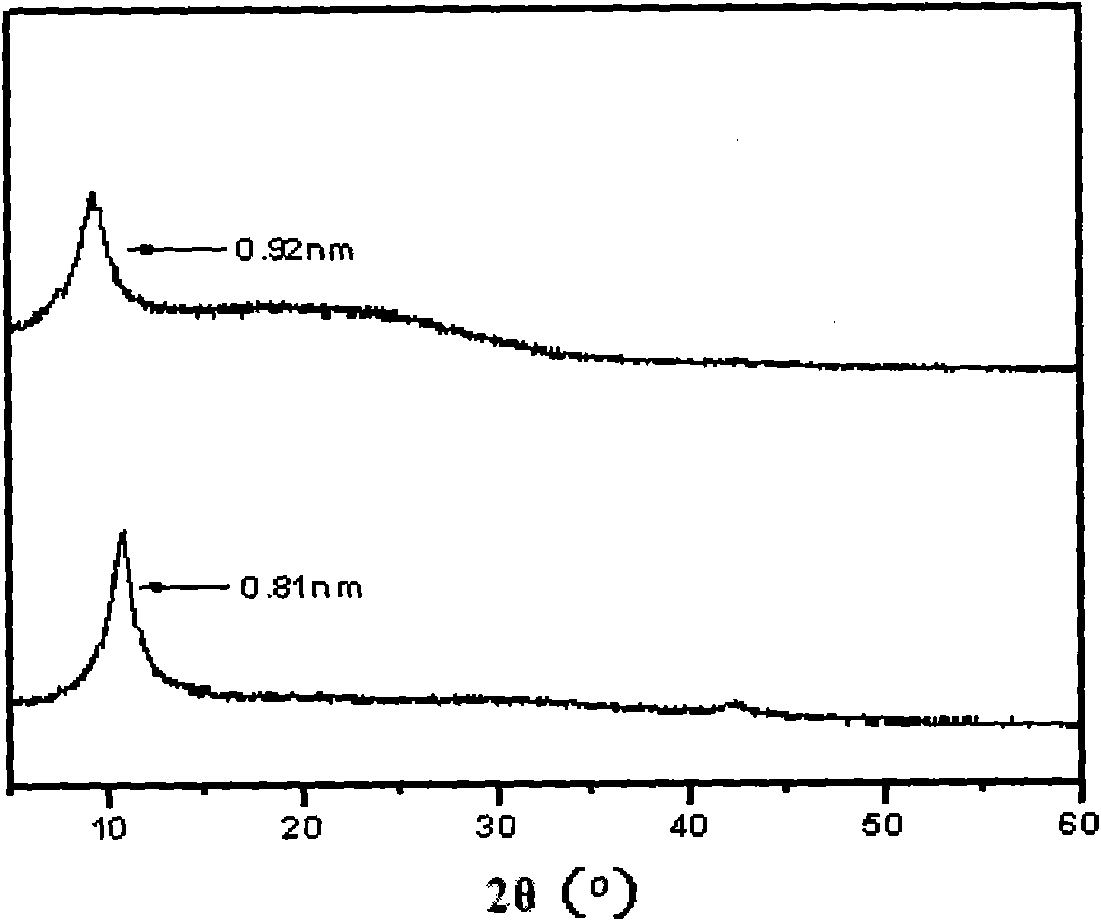

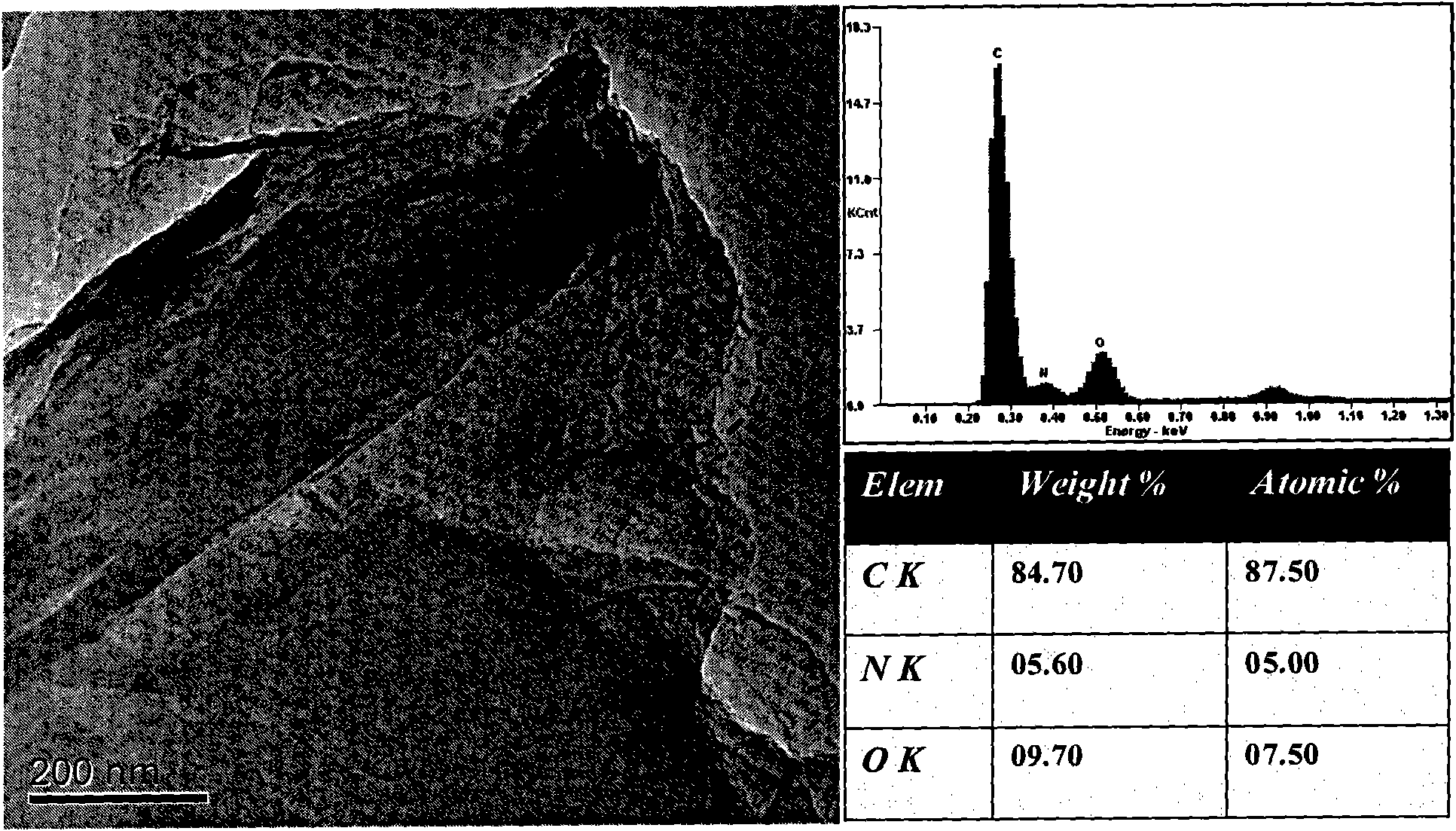

[0023] The invention provides a method for preparing a graphene oxide composite material. The preparation method comprises stirring an organic amine reagent and the graphene oxide sol at 30-120° C. for 3-72 hours in the presence of a solvent.

[0024] In the present invention, the amount of the solvent is enough to dissolve the organic amine reagent, but in a preferred situation, the weight ratio of the organic amine reagent to the organic solvent is 1:120-400. The weight ratio of graphene oxide to organic amine reagent in the graphene oxide sol is preferably 1:1-3.

[0025] In the present invention, the organic amine reagent is one or more selected from aromatic amines, peptides and alkyldiamines. Preferably, the organic amine reagent is one or more of p-phenylenediamine, aniline, cystine, glycine, glycine and ethylenediamine.

[0026] In the present invention, the solvent may be lower aliphatic alcohol or water, and the lower aliphatic alcohol is preferably ethanol or ethyl...

Embodiment 1

[0034] (1) Preparation of graphene oxide

[0035] Take 1g of natural flake graphite (10-100 μm in particle size) and add it to 30ml of concentrated sulfuric acid with a concentration of 98% by weight, stir in an ice bath at 0°C for 12h, then add 3g of potassium permanganate, stir at 35°C for 24h, until mixed The solution is earthy red, add 50ml of water to dilute, control the temperature at 90°C and stir for 0.5h, add 5ml of hydrogen peroxide with a concentration of 30% by weight, the solution turns golden yellow, and then use a concentration of 5% by weight hydrochloric acid at a speed of 5000r / min Centrifugal washing (200ml × 3 times) under centrifugal washing (200ml × 3 times), centrifugal washing (200ml × 3 times) with deionized water at a rotating speed of 15000r / min, the colloidal product after washing was added to water, and ultrasonically dispersed to obtain a concentration of 2mg / ml Graphene oxide sol.

[0036] (2) Amine functionalization of graphene oxide

[0037] ...

Embodiment 2

[0043] (1) Preparation of graphene oxide sheets

[0044] Take 1g of natural flake graphite (10-100μm in particle size) and add it to 20ml of 98% concentrated sulfuric acid, stir in an ice bath at 0°C for 4h, then add 5g of potassium permanganate, stir at 20°C for 48h, until the mixture is earthy red After adding 100ml of water to dilute, control the temperature at 70°C and stir for 1h, add 15ml of 10% by weight hydrogen peroxide, the solution turns golden yellow, then use 3% hydrochloric acid to wash centrifugally at a speed of 5000r / min (200ml×3 times), Centrifuge and wash with deionized water at a speed of 15000r / min (200ml×3 times), add the washed colloidal product into water, and ultrasonically disperse to obtain a graphene oxide sol with a concentration of 2mg / ml.

[0045] (2) Amine functionalization of graphene oxide

[0046] Dissolve 600mg of p-phenylenediamine in 200ml of ethanol, then mix it with 100ml of graphene oxide sol with a concentration of 2mg / ml as described...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com