Manufacturing method of color filter substrate and exposure mask for color filter substrate

A technology of color filter substrate and manufacturing method, which is applied to the photoplate-making process of the pattern surface, the original for photomechanical processing, optics, etc., to achieve the effect of sufficient correction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

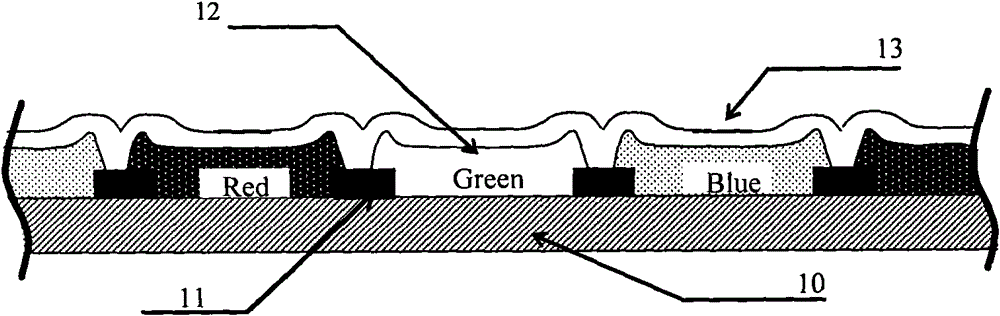

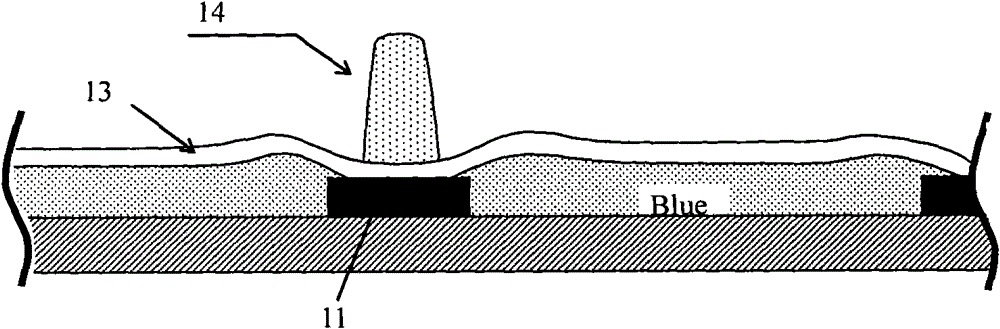

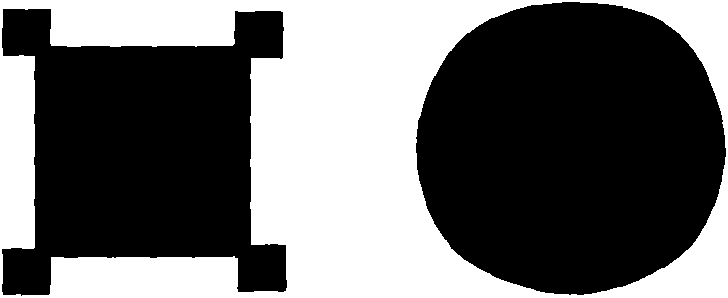

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] Generally, the manufacturing process of the color filter substrate is divided into four steps.

[0036] The first step is to form a light-shielding pattern layer on a transparent substrate.

[0037] Introduced here is the realization of the pigment dispersion method: in this first step, first use a photosensitive composition (photoresist) to form a certain film thickness on a glass substrate through slit coating, and then use a hot plate to carry out 90 degrees Celsius , After 120 seconds of heating (preheating treatment), use a proximity exposure machine equipped with a high-pressure mercury lamp and a mask with a specified pattern, at 60mJ / cm 2 , Exposure GAP200μm conditional exposure. Afterwards, the development is carried out with a transport-type developing device, that is, the potassium hydroxide-based developer CDK-1 is a developer solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com