A composite insulator tension string for overhead transmission lines

A technology for overhead transmission lines and composite insulators, applied in circuits, insulators, suspension/strain insulators, etc., can solve the problems of mechanical performance decline, weaken the connection strength between mandrel and end fittings, etc., to ensure the effect of mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

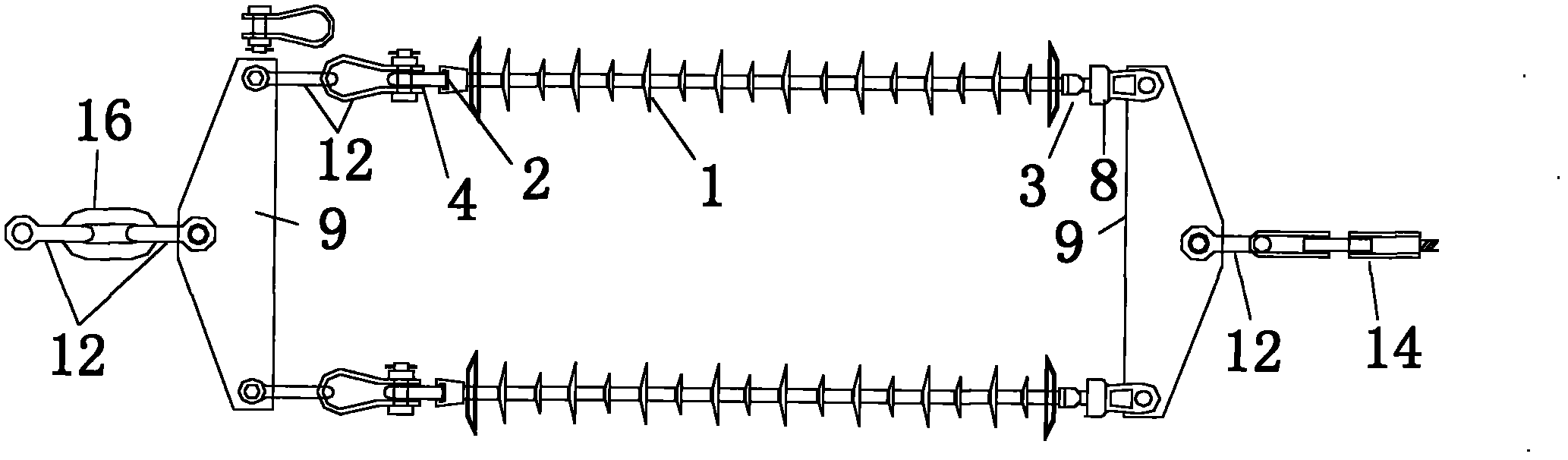

Embodiment 1

[0016] Embodiment 1, a kind of overhead transmission line composite insulator single conductor tension string (see figure 1 ), which includes two composite insulators 1, one end of each composite insulator 1 is provided with a ball-and-socket structure 2, and the other end is provided with a ball-joint structure 3, and the ball-and-socket structure 2 is connected to the grounding end fittings string, and the grounding end fittings string is composed of QP The inner arc U-shaped ring 12, the two-joint plate 9, the U-shaped ring 12, the extension ring 16, and the U-shaped ring 12 connected by the type ball head hanging ring 4, the ring-ring are connected successively to form, and each pair of ring-rings connected The inner arc U-shaped rings 12 are all connected with the two-joint plate 9, the two-joint plate 9 is connected with a U-shaped ring 12, the U-shaped ring 12 is connected with an extension ring 16, and the extension ring 16 is connected with a U-shaped ring 12, and the ...

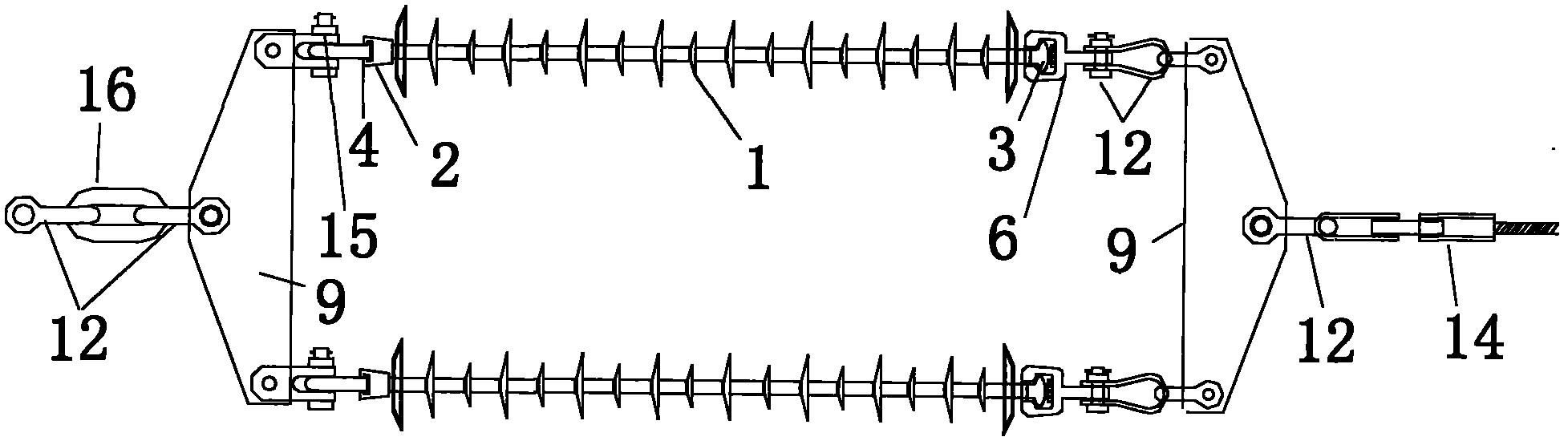

Embodiment 2

[0017] Embodiment 2, a kind of overhead power transmission line composite insulator single conductor strain string (see figure 2 ), which includes two composite insulators 1, one end of each composite insulator 1 is provided with a ball-and-socket structure 2, and the other end is provided with a ball-joint structure 3, and the ball-and-socket structure 2 is connected to the grounding end fittings string, and the grounding end fittings string is composed of QP Type ball head hanging ring 4, right-angle hanging plate 15, two-joint plate 9, U-shaped ring 12, extension ring 16, U-shaped ring 12 are sequentially connected to form, and each right-angle hanging plate 15 is connected with two-joint plate 9, and the two-joint The plate 9 is connected with a U-shaped ring 12 , the U-shaped ring 12 is connected with an extension ring 16 , and the extension ring 16 is connected with a U-shaped ring 12 , and the QP type ball head hanging ring 4 is connected with the ball-and-socket struct...

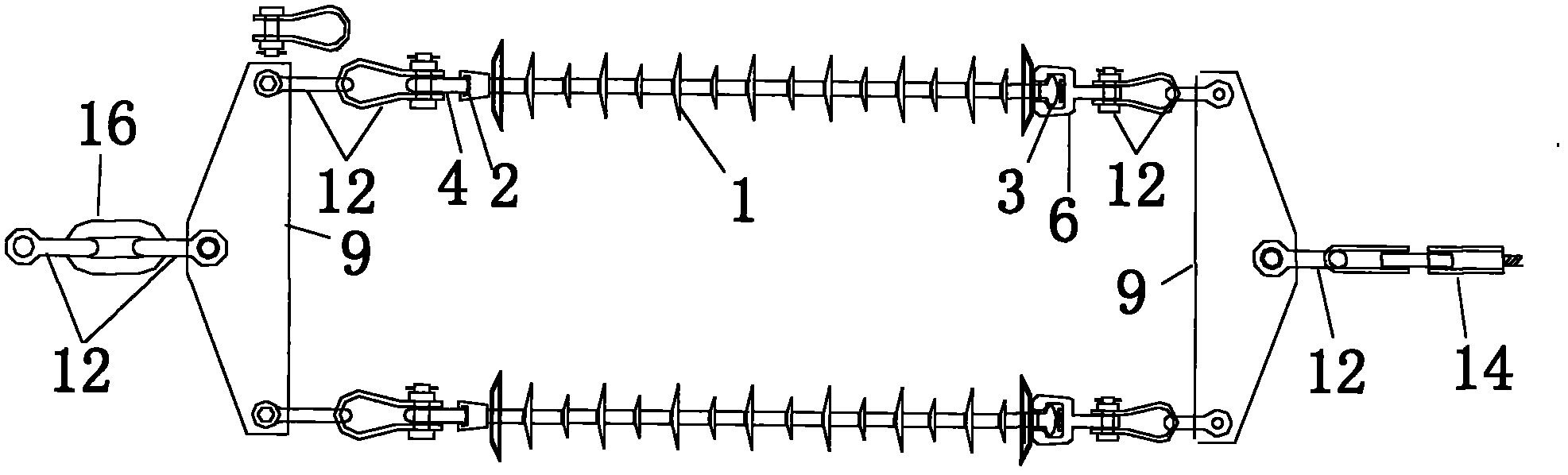

Embodiment 3

[0018] Embodiment 3, a kind of overhead transmission line composite insulator single conductor tension string (see image 3 ), which includes two composite insulators 1, one end of each composite insulator 1 is provided with a ball-and-socket structure 2, and the other end is provided with a ball-joint structure 3, and the ball-and-socket structure 2 is connected to the grounding end fittings string, and the grounding end fittings string is composed of QP The inner arc U-shaped ring 12, the two-joint plate 9, the U-shaped ring 12, the extension ring 16, and the U-shaped ring 12 which are connected by two pairs of rings and rings are connected in sequence, and each ring-ring is connected in sequence. The connected inner arc U-shaped rings 12 are all connected to the two-joint plate 9, the two-joint plate 9 is connected to a U-shaped ring 12, the U-shaped ring 12 is connected to an extension ring 16, and the extension ring 16 is connected to a U-shaped ring 12. QP ball The head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com