Permanent magnet machines specifically generators for wind turbines

A technology of wind turbines and permanent magnets, applied in wind power generation, electromechanical devices, magnetic circuits, etc., can solve problems such as increasing harmonic components, torque fluctuations, and structural noise of wind turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

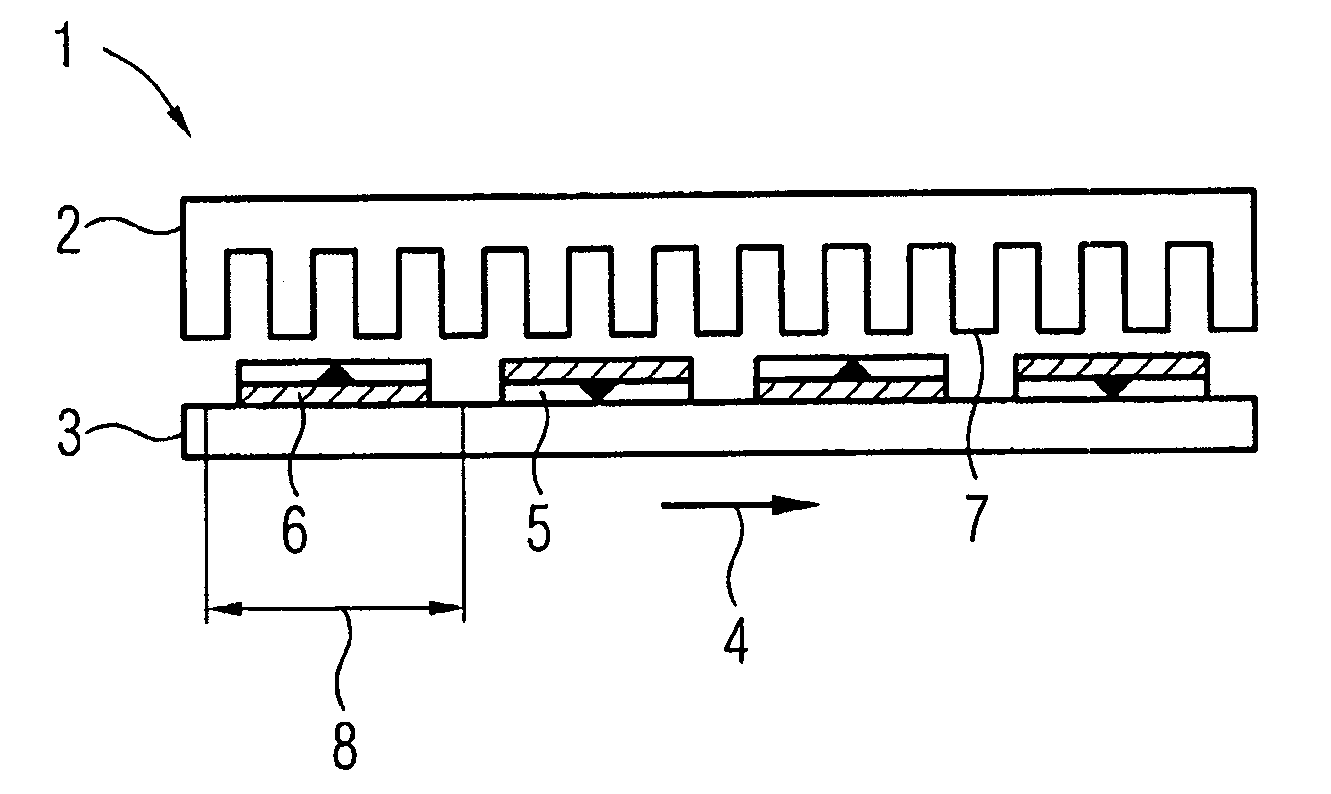

[0022] figure 1 A conventional permanent magnet machine 1 is shown, which is used as a generator for a wind turbine. The stationary stator 2 is usually included in the nacelle, which is located on top of the tower of the wind turbine. The rotor 3 moves rotatably around the stator 2 . In fact, stator 2 and rotor 3 are slightly bent, but in figure 1 In the schematic diagram of , the stator 2 and the rotor 3 are represented in a flat projection. Arrow 4 shows the circumferential direction in which the rotor 3 turns.

[0023] can from figure 1 It can be seen from the figure that a plurality of permanent magnets 5 , 6 are located on one side of the rotor 3 . The stator 2 includes a plurality of stator teeth extending vertically toward the rotor 3 . Each stator tooth 7 has a stator coil (in figure 1 not shown). Each of the plurality of permanent magnets 5, 6 forms a pole 8, all alternating in succession, ie a permanent magnet with a north pole on top followed by a permanent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com