A structurally improved hot press and a hot press forming method thereof

A technology of hot-press forming and hot-pressing machine, applied in the field of hot-pressing, can solve the problems of inability to process, high power, low operation safety performance, etc., and achieve the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

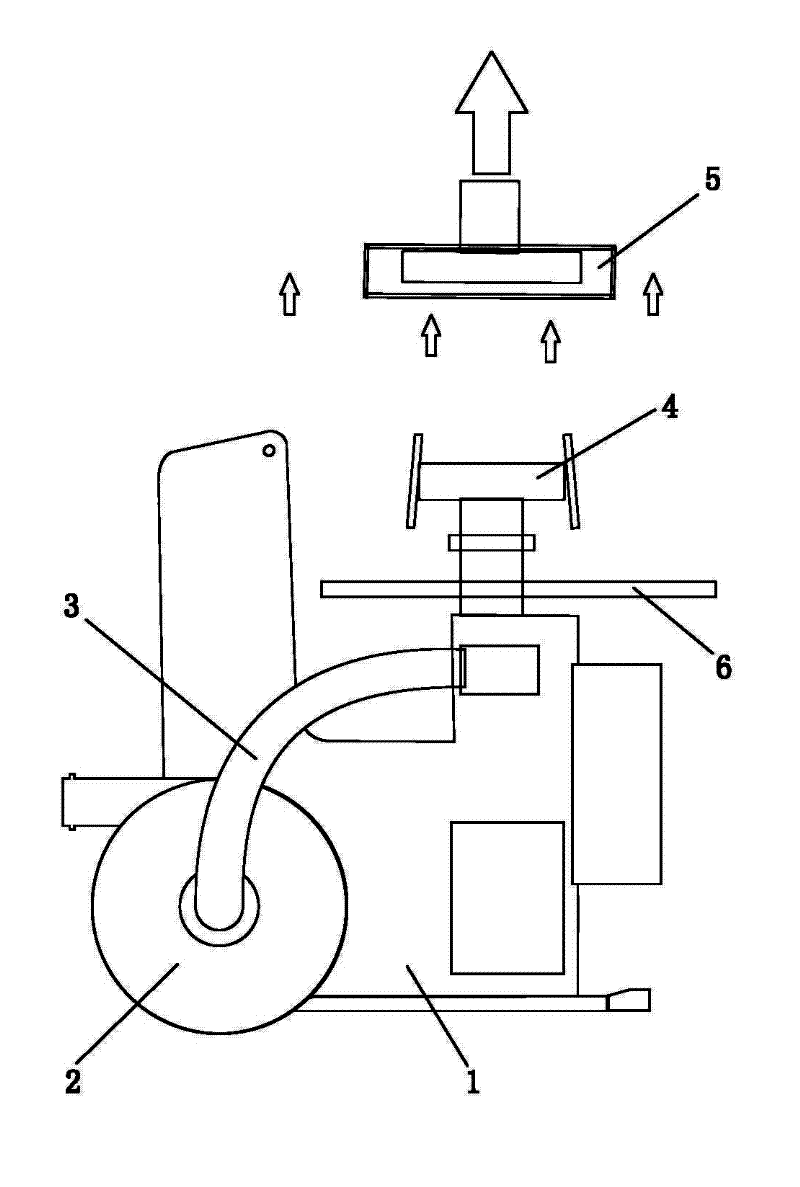

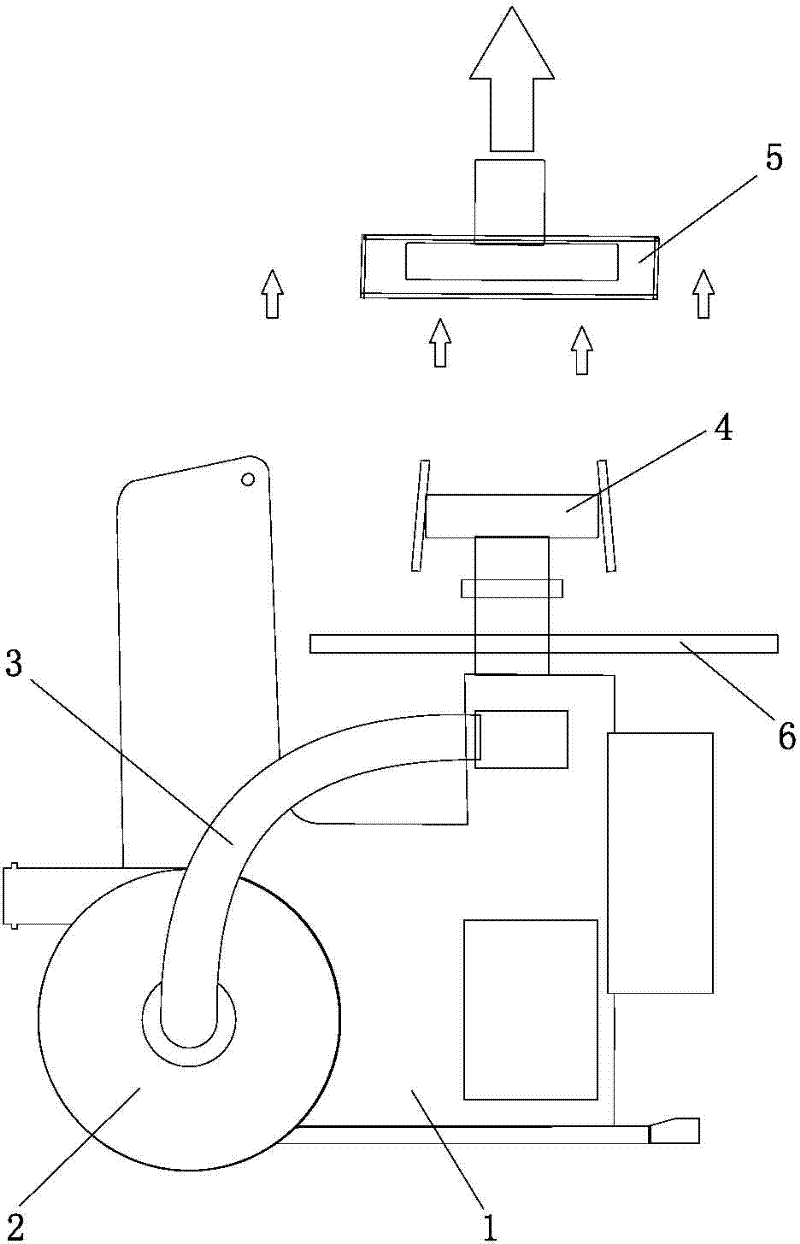

[0033] Embodiment one, such as figure 1 As shown, a heat press machine with improved structure includes a base 1, the base 1 is fixedly connected with a draft device 2, the output end of the draft device 2 is connected with a suction duct 3, the base 1 The upper surface is provided with a lower module 4, the top of the lower module 4 is provided with an upper module 5 used in conjunction with the lower module 4, the upper module 5 is connected with a heating device, and one end of the suction duct 3 is connected to the lower module 4. The modules 4 communicate and extend on the upper surface of the lower module 4, wherein the temperature of the upper module 5 and the lower module 4, the downward movement of the upper module 5 and the positions of the upper module 5 and the lower module 4 are all controlled by oil pressure. The system is precisely controlled. When the invention is in operation, the temperature of the heating tube is controlled by the temperature controller with...

Embodiment 2

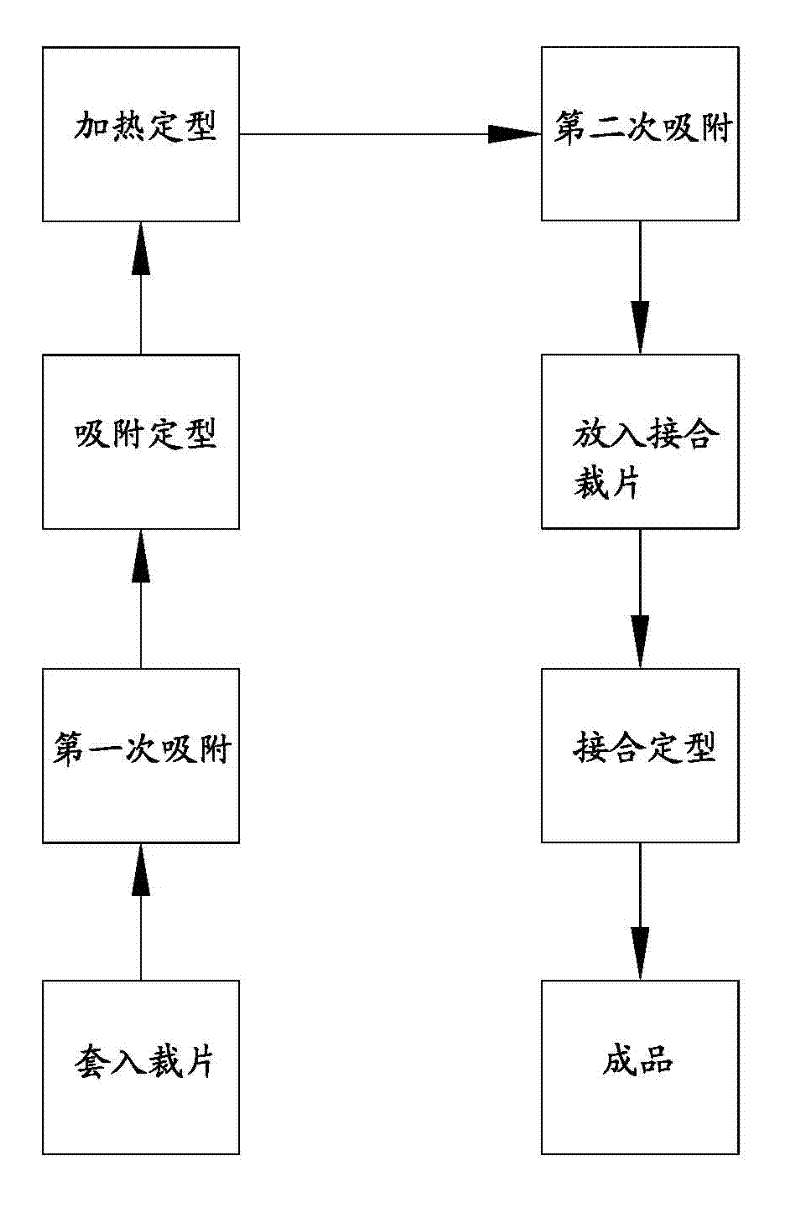

[0035] Embodiment 2, the thermocompression forming method of the structurally improved thermocompression machine, comprises the following steps:

[0036] a. Insert the cut pieces, put the cut pieces into the lower module 4 of the heat press, and spread the cut pieces on the lower module 4 as far as possible when placing the cut pieces.

[0037] b. For the first adsorption, the exhaust device 2 is turned on to adsorb the pieces inserted into the lower module 4 to the upper surface of the lower module 4 .

[0038] c. Adsorption and shaping, place a shaping film on the upper surface of the adsorbed piece and continue to absorb, so that the shape of the piece will not be moved, and the piece will be evenly flattened.

[0039] d. Heating and shaping. At this time, turn off the ventilation device 2 to stop the adsorption, and control the upper module 5 to press down to preheat and heat the shaping film and the cutting pieces that are bonded together. Only the cutting pieces are shap...

Embodiment 3

[0045]Embodiment 3, the difference from the above-mentioned embodiments is that in this embodiment, the temperature for preheating and setting the cut piece and the shaping film is 60-140°C, and the pressure for preheating and setting the cut piece and the shaping film is 600-1800kg, the preheating time for the cut piece and the shaping film is 6-14s.

[0046] In this embodiment, the temperature at which the cut pieces and the joint pieces are pressurized, bonded and shaped is 60-240°C, and the pressure at which the cut pieces and the joined pieces are pressure-bonded and shaped is 600-4500kg. And the preheating time for pressurized bonding and shaping of the bonded pieces is 35-135s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com