Antibacterial plastic master batch and manufacturing method thereof and antibacterial chopping board prepared from antibacterial plastic master batch

An antibacterial plastic and cutting board technology, applied in the field of cutting boards, can solve the problems of uneven distribution of antibacterial agents, unclear antibacterial effect, and high cost of antibacterial agents, achieve complete and effective antibacterial efficacy, improve binding stability, and improve antibacterial The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

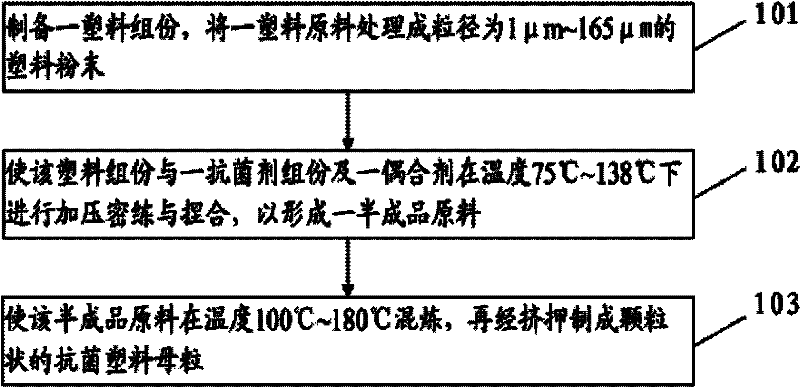

Method used

Image

Examples

Embodiment 1

[0075] (1) Preparation of antibacterial plastic masterbatch: Mix 20 parts by weight of antibacterial agent component with 80 parts by weight of plastic component and 3 parts by weight of coupling agent, and mix them with a compact mixer at a temperature of about 125-130°C. After compacting and kneading for about 25 minutes, it is sent to a twin-screw extruder for mixing, and then granulated by a die-head rotary knife eager-cutting granulator to obtain antibacterial plastic masterbatches. Among them, the antibacterial agent component is a nano-Ag / ZnO composite powder purchased from Top Nano Technology Co., Ltd., the product model is SP-AEZ203, and contains 55,000 ppm of nano-silver and 945,000 ppm of nano-zinc oxide. The plastic component is 40 parts by weight of polyethylene (PE) mixed with 40 parts by weight of thermoplastic rubber (TPR), and both polyethylene and thermoplastic rubber are ground into plastic powder with a particle size range of 25 μm to 165 μm. The coupling a...

Embodiment 2

[0090] (1) Prepare antibacterial plastic master batch: manufacture antibacterial plastic master batch with the method in (1) in embodiment 1, the composition of this plastic component and coupling agent is identical with embodiment 1, plastic component, antibacterial agent component and coupling agent The ratio of the mixture is also the same as in Example 1, and the difference is only that the composition of the antibacterial agent component is different from that of Example 1. The antibacterial agent component contains 49500ppm of nano-silver, 850500ppm of nano-zinc oxide, and 1225000ppm of bamboo preparations. long carbon content.

[0091] (2) Manufacture of the body of the antibacterial cutting board: manufacture the body X2 of the antibacterial cutting board with the method of (2) in Example 1. The plate body X2 thus produced contains 396ppm of nano-silver, 6804ppm of nano-zinc oxide and 9800ppm of bamboo long carbon.

[0092] (3) Manufacture the cutting board body Y2 wi...

Embodiment 3

[0104] (1) Prepare antibacterial plastic master batch: manufacture antibacterial plastic master batch with the method in (1) in embodiment 1, the composition of this plastic component and coupling agent is identical with embodiment 1, plastic component, antibacterial agent component and coupling agent The ratio of the mixture is also the same as in Example 1, and the difference is only that the composition of the antibacterial agent component is different from that of Example 1. The antibacterial agent component contains 68750ppm of nano silver, 472500ppm of nano zinc oxide, and 62500000ppm of bamboo preparations. long carbon content.

[0105] (2) Manufacture the board body of the antibacterial cutting board: manufacture the board body X3 of the antibacterial cutting board with the method of (2) in the embodiment 1. The board body X3 thus produced contains 550ppm of nano-silver, 9450ppm of nano-zinc oxide and 500000ppm of bamboo long carbon.

[0106] (3) Manufacture the board...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com