Conductive adhesive film with high peel strength and preparation method thereof

A conductive adhesive film, high peeling technology, applied in the direction of conductive adhesives, chemical instruments and methods, adhesives, etc., can solve the problems of many conductive particles, inconvenient use, high production cost, etc., to achieve improved peel strength and increased overlap probability , The effect of shielding effect enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

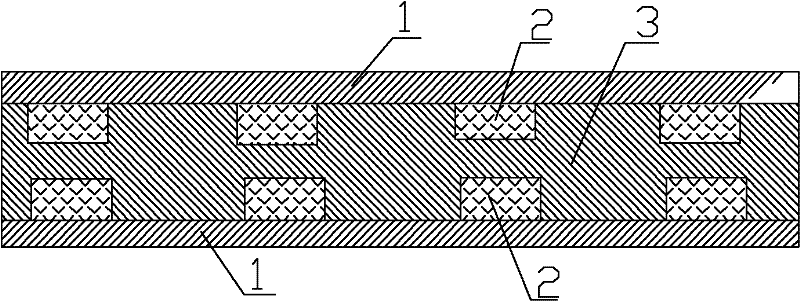

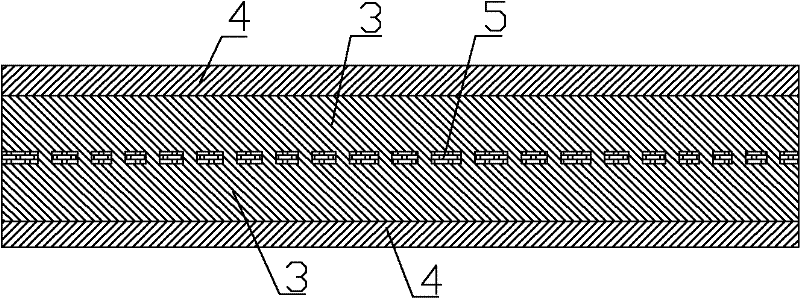

[0035] High peel strength conductive adhesive film with via holes, such as figure 2 As shown, a conductive adhesive layer 3 is included, and the outer surface of the conductive adhesive layer 3 may be covered with a protective release film 4 . The protective film can have only one layer of protective film; it can also be two layers of protective film, one of which can be a release film, and the other layer can be a release paper. The protective film can effectively protect the outer surface of the conductive adhesive layer 3 from being polluted by foreign dust and other impurities. The conductive adhesive layer 3 is provided with a layer of conductive layer 5, and the conductive adhesive is coated on both sides of the conductive layer 5; The conductive adhesive on the side surface contacts through the through hole and is bonded together, which can effectively increase the peel strength between the conductive adhesive and the conductor layer.

[0036] The through holes on th...

Embodiment 2

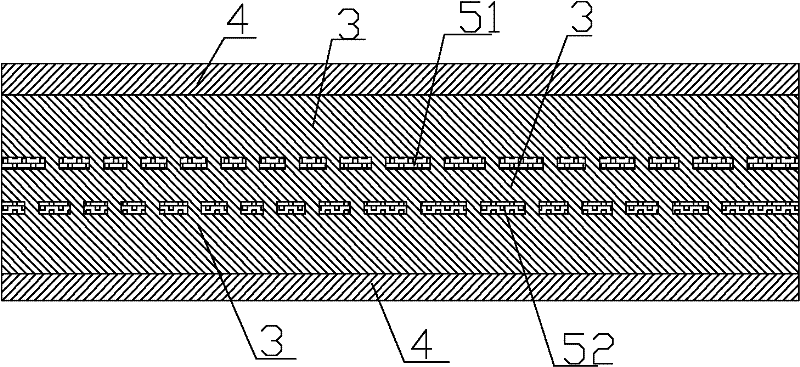

[0038] like image 3 As shown, the conductor layer 5 can be provided with two layers inside the conductive adhesive layer 3 , namely a first conductor layer 51 and a second conductor layer 52 . The first conductive layer 51 and the second conductive layer 52 separate the conductive adhesive layer 3 into three layers, that is, the conductive adhesive layer 3 is filled or coated between the first conductive layer 51 and the second conductive layer 52 by coating or dipping. , forming a stacked layered structure; to enhance the conductivity and shielding effect.

Embodiment 3

[0040] like Figure 4 As shown, the conductor layer 5 may be provided with three layers in the conductive adhesive layer 3 , namely the first conductor layer 51 , the second conductor layer 52 and the third conductor layer 53 . The first conductor layer 51 , the second conductor layer 52 and the third conductor layer 53 separate the conductive adhesive layer 3 into four layers to form a stacked layered structure to enhance the conduction and shielding effects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com