Special high temperature resistant adhesive resins for steel-plastic composite pipe and preparation method thereof

A steel-plastic composite pipe and bonding resin technology, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesives, adhesive types, etc., to achieve the effects of high stability, excellent corrosion resistance, and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

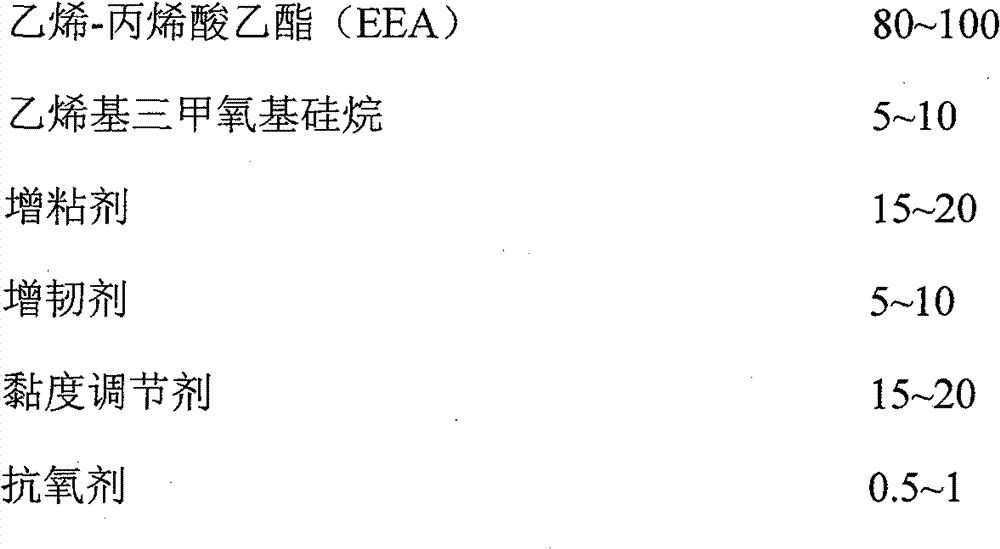

[0024] Components (parts by mass) of special adhesive resin for high temperature resistance of steel-plastic composite pipe:

[0025]

[0026] Raise the temperature of the reactor with agitator to 140°C. After controlling the temperature to be constant, add plasticizer, wax, tackifier and anti-aging agent into the reactor, stir, and pass through nitrogen protection, and stir until the solid material Melt completely, then raise the temperature to 160-170°C, add EEA resin, after EEA is completely melted, add other additives and stir well. Pour the prepared resin into a container coated with anti-sticking agent after cooling down a little to obtain the bonding resin.

Embodiment 2

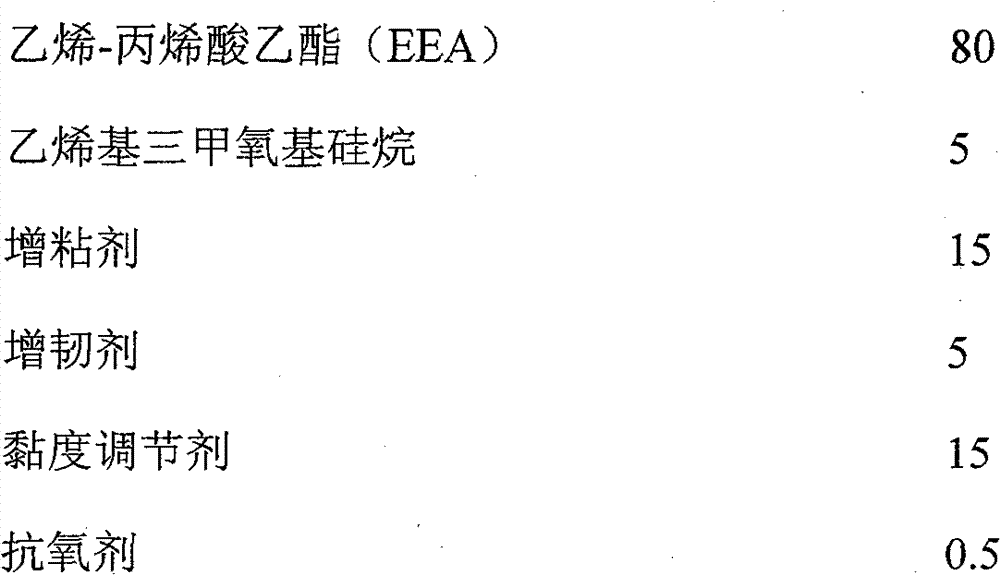

[0028] Components (parts by mass) of special adhesive resin for high temperature resistance of steel-plastic composite pipe:

[0029]

[0030] Raise the temperature of the reactor with agitator to 150°C. After controlling the temperature to be constant, add plasticizer, wax, tackifier and anti-aging agent into the reactor, stir, and pass through nitrogen protection, and stir until the solid material Melt completely, then raise the temperature to 160-170°C, add EEA resin, after EEA is completely melted, add other additives and stir well. Pour the prepared resin into a container coated with anti-sticking agent after cooling down a little to obtain the bonding resin.

Embodiment 3

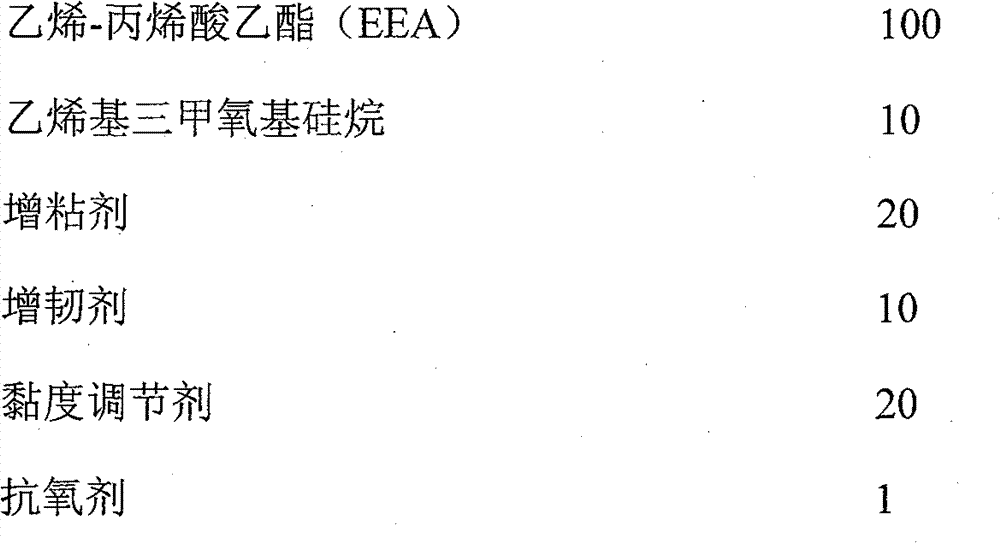

[0032] Components (parts by mass) of special adhesive resin for high temperature resistance of steel-plastic composite pipe:

[0033]

[0034] Raise the temperature of the reactor with agitator to 145°C. After controlling the temperature to be constant, add plasticizer, wax, tackifier and anti-aging agent into the reactor, stir, and pass through nitrogen protection, and stir until the solid material Melt completely, then raise the temperature to 160-170°C, add EEA resin, after EEA is completely melted, add other additives and stir well. Pour the prepared resin into a container coated with anti-sticking agent after cooling down a little to obtain the bonding resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com