A soft stop control device for automobile electric windows

A technology of stop control and control device, which is applied to vehicle components, door/window accessories, transportation and packaging, etc., which can solve the problems of reducing the service life of the window motor and increasing the current, and achieves reliable performance, simple structure and easy implementation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

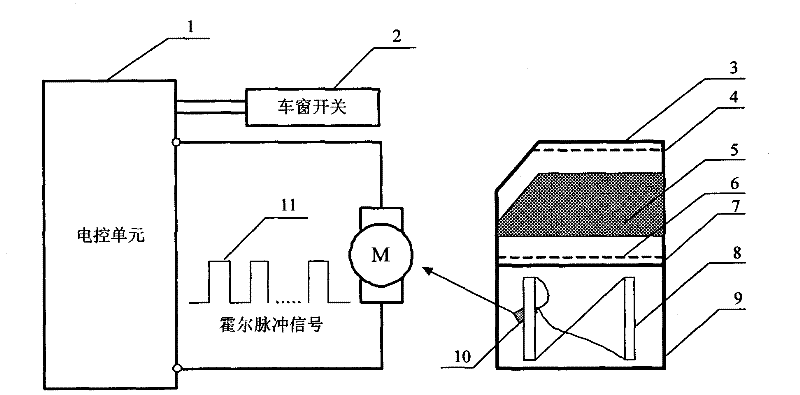

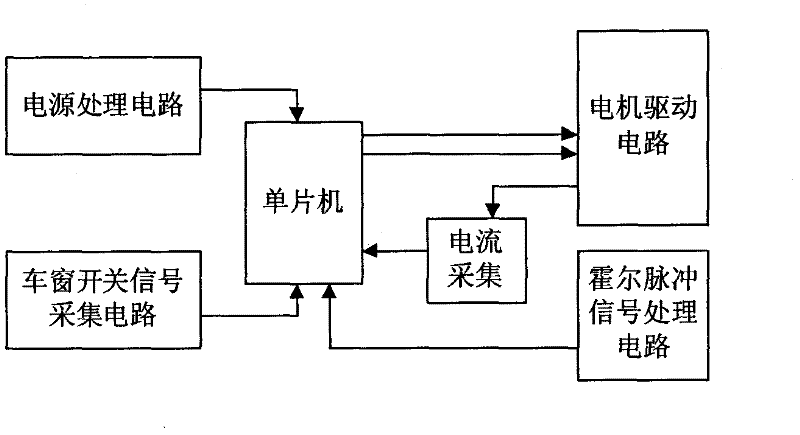

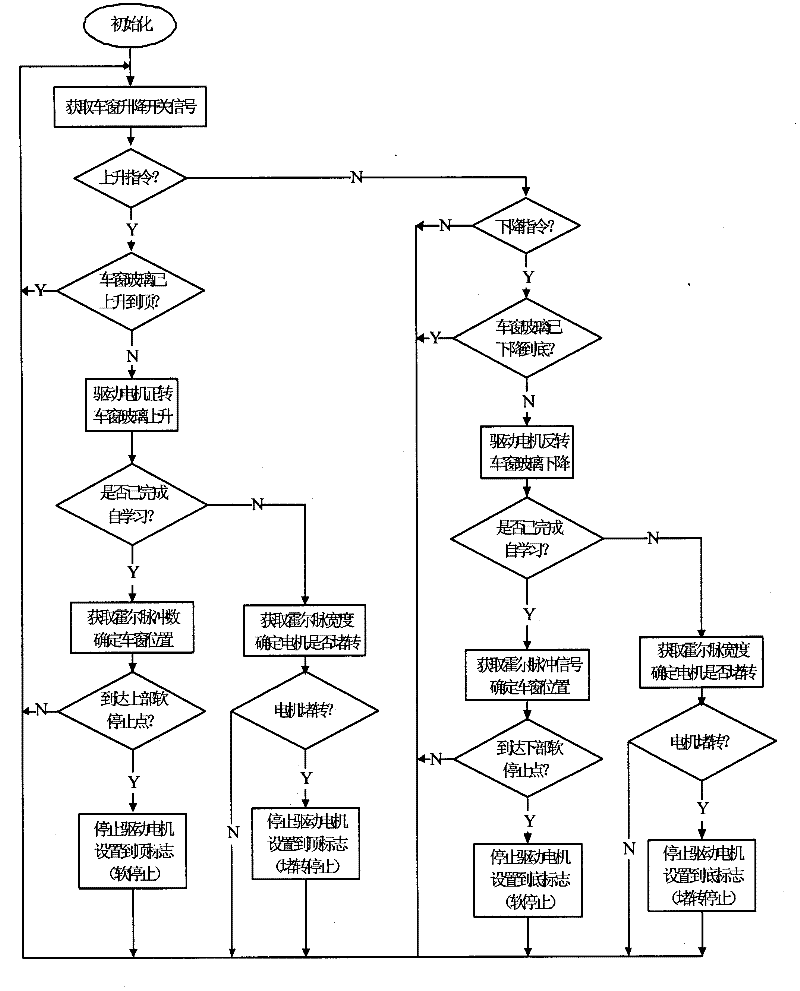

[0016] figure 1 It is a schematic diagram of the position and connection of the soft stop control device for the electric window of the automobile of the present invention. The control device is composed of a door frame 9, a guide rail 8, a window glass 5, a window motor 10 with a Hall sensor, a window switch 2, and an electric control unit 1; the window guide rail 8 is fixed on the door frame 9, and the electric control The unit 1 can be fixed on the door frame 9, and can also be integrated with the window motor 10 and then fixed on the guide rail 8. The signal of the window switch 2 is processed by the acquisition circuit inside the control unit 1 and then connected to the input terminal of the single-chip microcomputer. After being processed by the motor drive circuit, the output is connected to the window motor 10 through wires, and the electronic control unit 1 drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com