Explosion-proof engine exhaust system

An exhaust system and engine technology, applied in engine components, machines/engines, exhaust devices, etc., can solve the problems of large exhaust system power loss, exhaust system smoke blockage, uneconomical use, etc., and achieve low power loss. , The effect of reducing downtime loss and fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

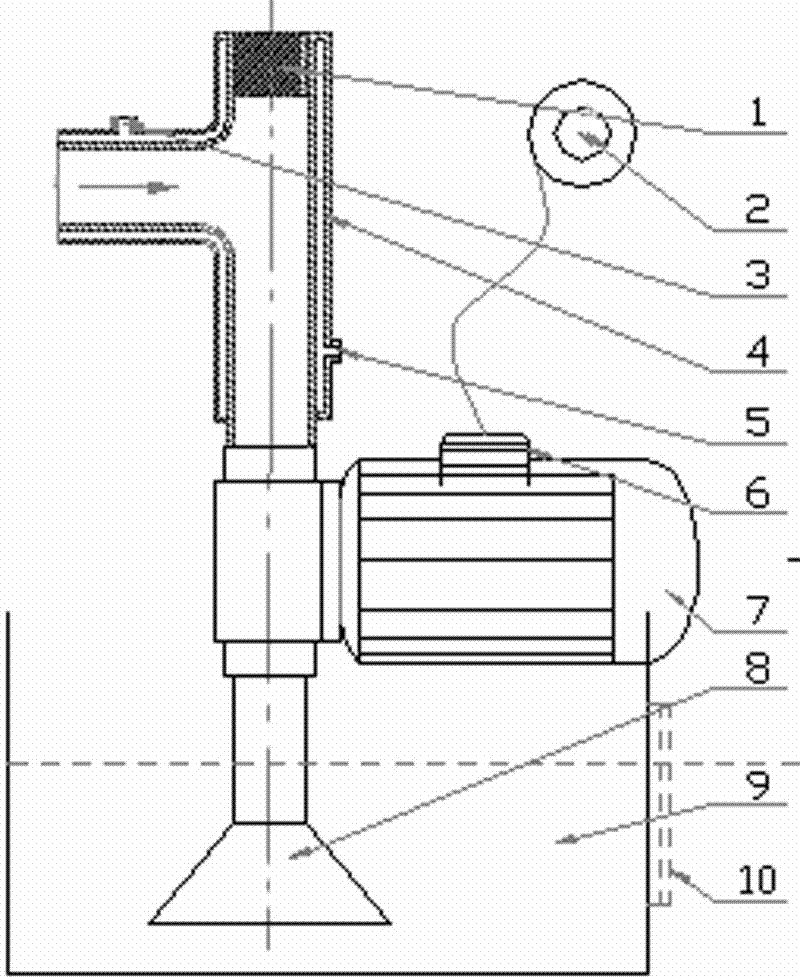

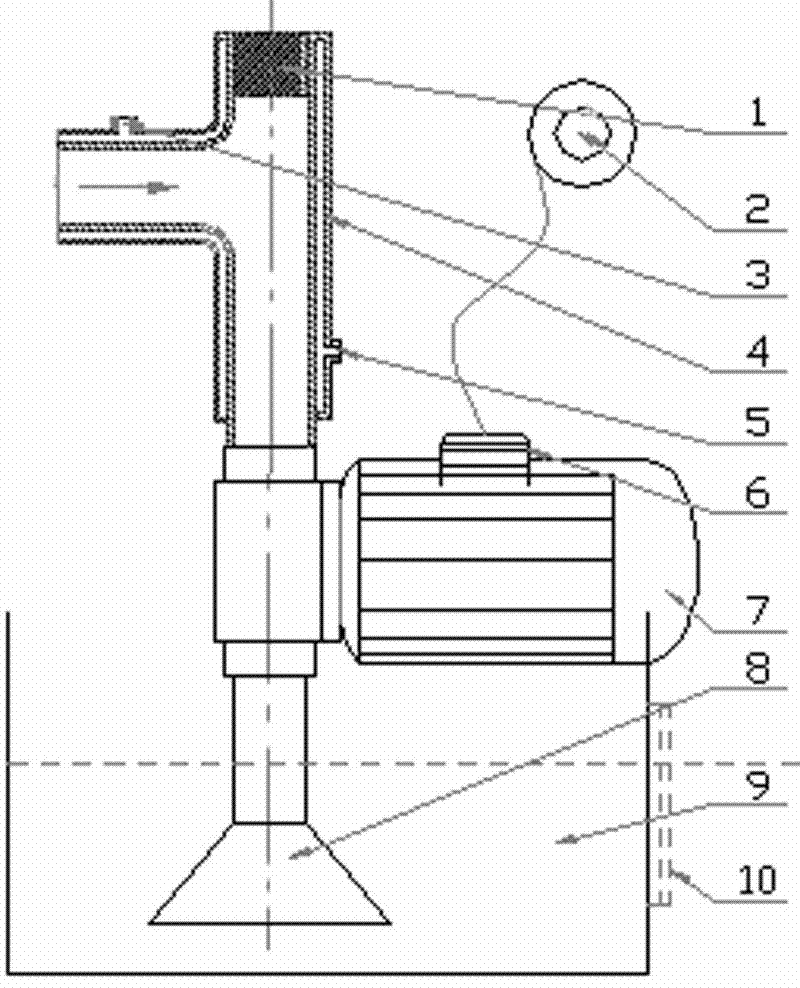

[0013] The explosion-proof engine exhaust system shown in Figure 1 is composed of a water-jacketed three-way exhaust pipe 4, an air extractor 7, a water tank 9, water, an engine speed sensor 2 and a control system 6. The air inlet of the water-jacketed three-way exhaust pipe 4 is connected to the exhaust gas outlet of the engine, one of the exhaust ports is provided with a flameproof grille 1, and the other exhaust port is provided with an active air extraction system. The water jacket of the water-jacketed three-way exhaust pipe 4 has a cooling water inlet 3 and a cooling water outlet 5, and the cooling water flows through the water jacket to cool the three-way exhaust pipe to reduce and cool the surface temperature of the exhaust pipe. , so that the surface of the exhaust pipe meets the requirements of Class I explosion-proof. The active air extraction system has an air extractor 7, a water tank 9, water, an engine speed sensor 2 and a control system 6, the inlet of the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com