Manufacturing method of metal-sheet-based negative temperature coefficient (NTC) thermistor temperature sensor

A technology of temperature sensor and thermistor, which is applied to thermometers, thermometers, instruments, etc. that use electric/magnetic elements that are directly sensitive to heat, can solve the problem that the reaction speed cannot meet the requirements of high sensitivity of temperature detection, etc. The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

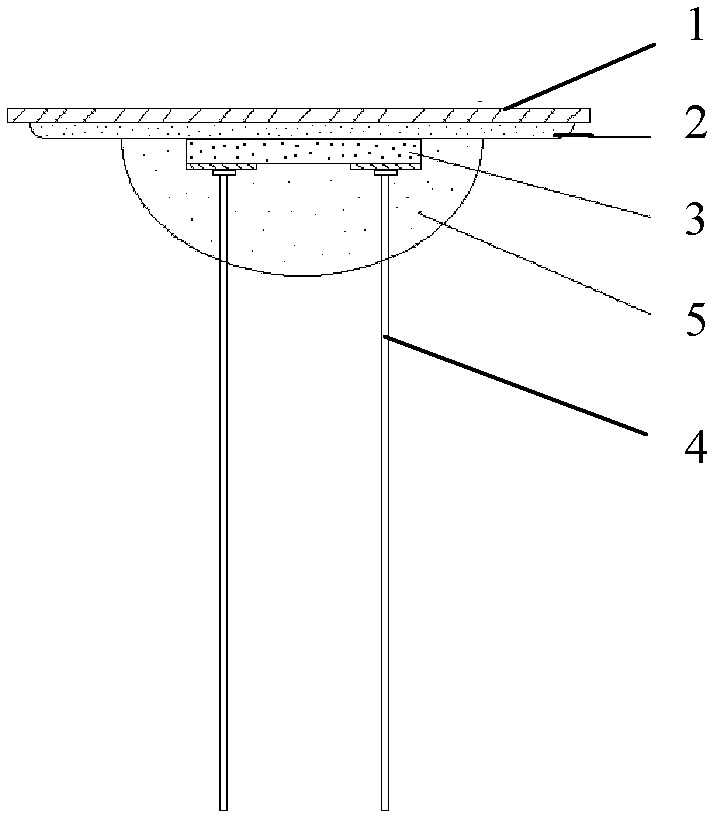

[0047] Such as figure 2 As shown, the NTC thermistor temperature sensor based on the metal substrate of the present invention includes a metal substrate 1, and at least one NTC thermistor chip 3 is pasted on the metal substrate 1 by a glass insulating medium layer 2, The metal electrodes of the NTC thermistor chip 3 are correspondingly connected to lead wires 4 , and the connection between the NTC thermistor chip 3 and the lead wires 4 and the periphery of the NTC thermistor chip 3 are coated with a glass encapsulation layer 5 .

[0048] In the present invention, the thickness range of the metal substrate 1 is 0.05-0.2mm, and the thickness of the metal substrate 1 is thinner to ensure better thermal conductivity and shorter heat conduction time.

[0049] In addition, the thickness range of the NTC thermistor chip 2 in the present invention is 0.2-2 mm.

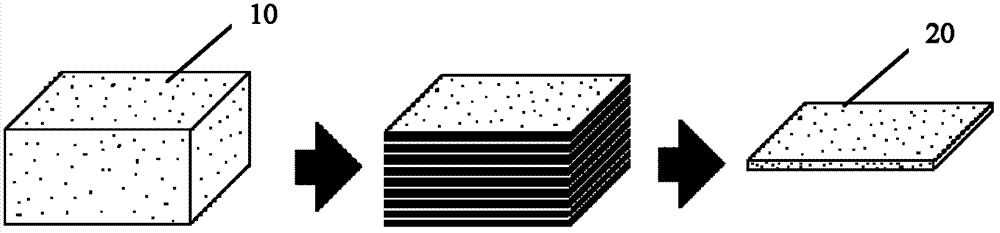

[0050] The present invention also discloses a manufacturing method of an NTC thermistor temperature sensor based on a meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com