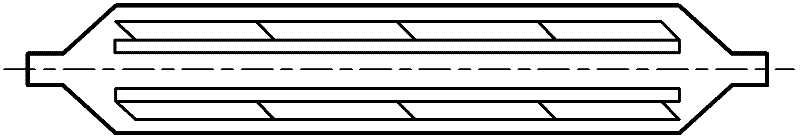

Pantograph Crack Fault Detection Method Based on Moving Parallel Window in Curve Wave Domain

A technology of fault detection and pantograph, applied in the direction of optical testing flaws/defects, instruments, characters and pattern recognition, etc., can solve problems such as pantograph-catenary accidents, and achieve the effect of detection and effective extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0085] Below the present invention is described in detail in conjunction with example:

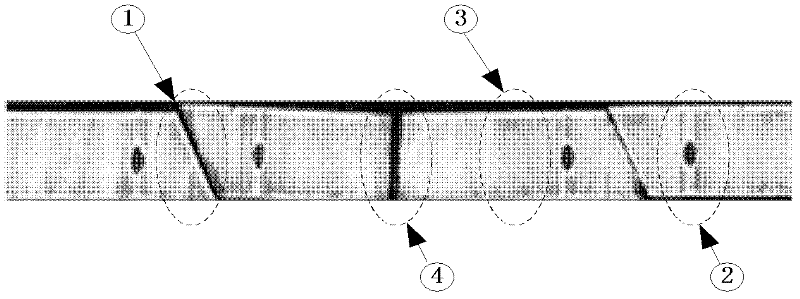

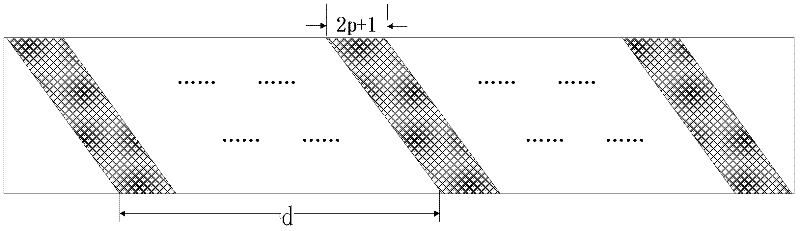

[0086] The front end of the pantograph has serious scratches on the slide plate, and there is a vertical crack in the middle of the back end slide plate. The extraction results of the slide plate are as follows: Figure 4 As shown, the size of the image is 47×1508×3. Due to the cracks in the skateboard itself and the inaccurate installation, the short slider on the skateboard has been deformed and displaced, so that the extracted skateboard image contains a part of the background. Image, the top and bottom edges of the skateboard are not strictly horizontal either. The results of crack extraction experiments are as follows: Figure 5 shown. like Figure 6 , select two pictures with light exposure problems to verify the algorithm. There is a vertical crack in the middle of picture (a), there is a vertical crack in the middle of picture (b), and there is a crack parallel to the joint in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com