A doubly-fed motor testing system and testing method thereof

A technology of doubly-fed motor and test system, applied in the direction of motor-generator test, can solve the problems of complex test tooling, increased equipment cost, and high equipment cost, and achieve the effect of saving test cost, improving test efficiency, and small speed regulation range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

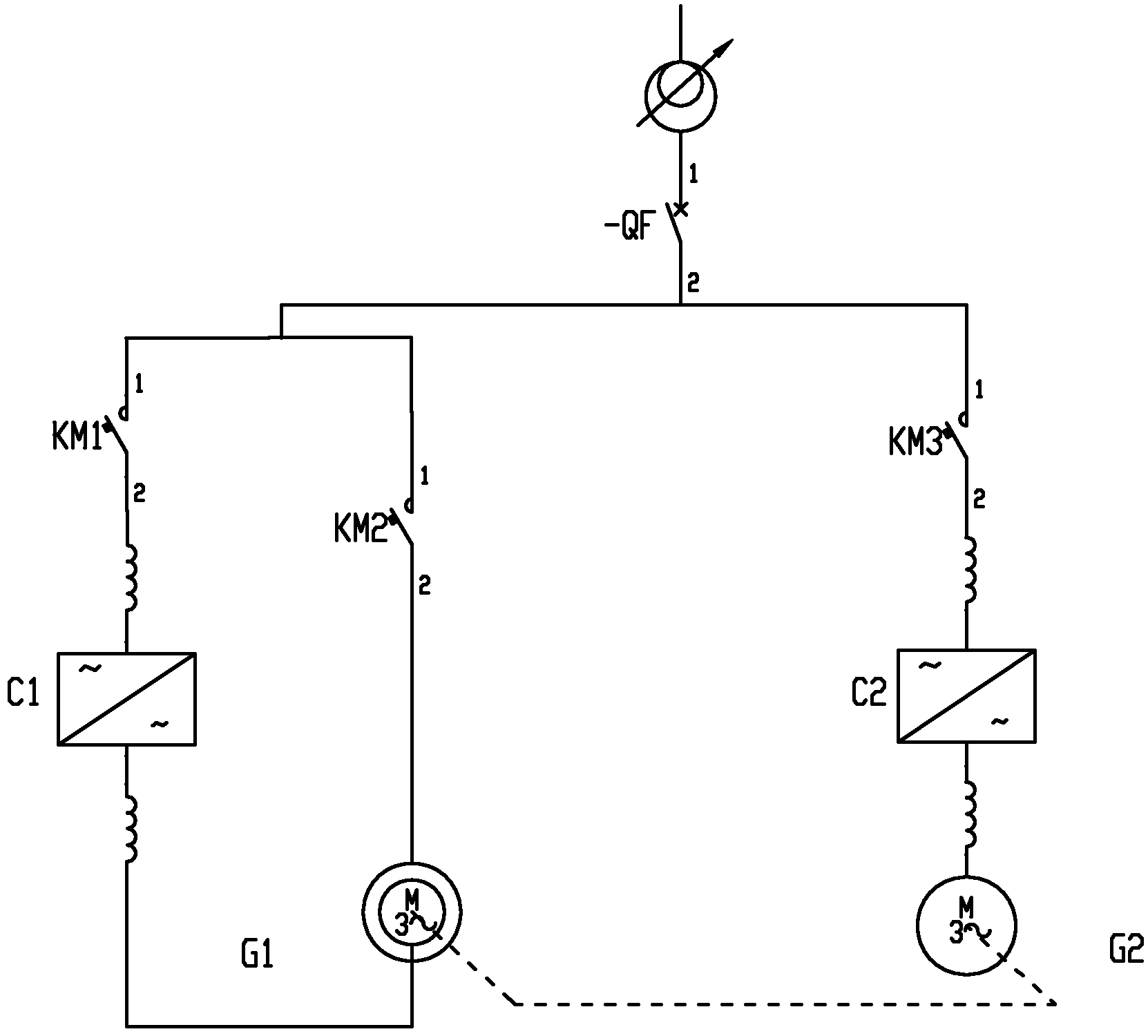

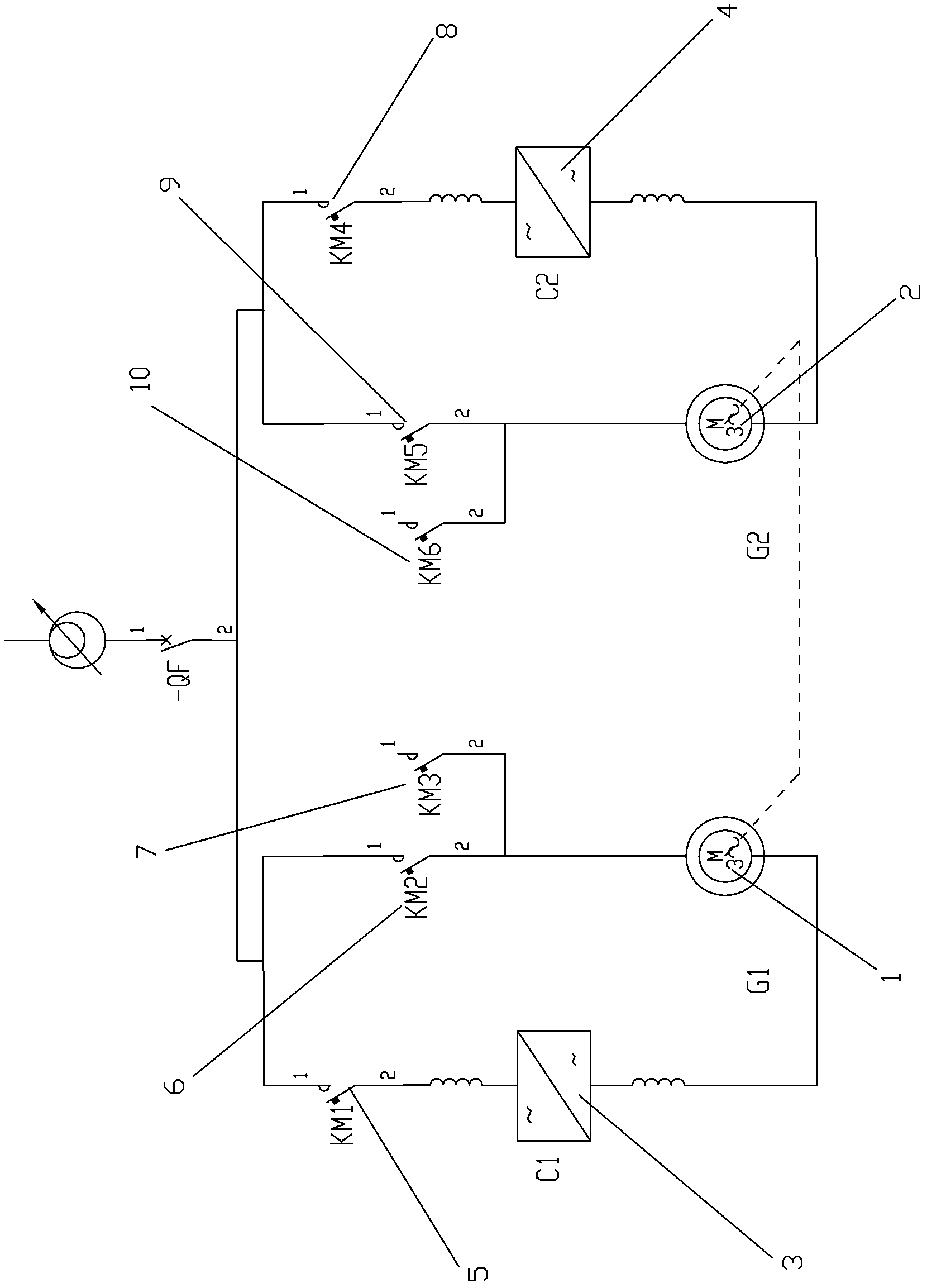

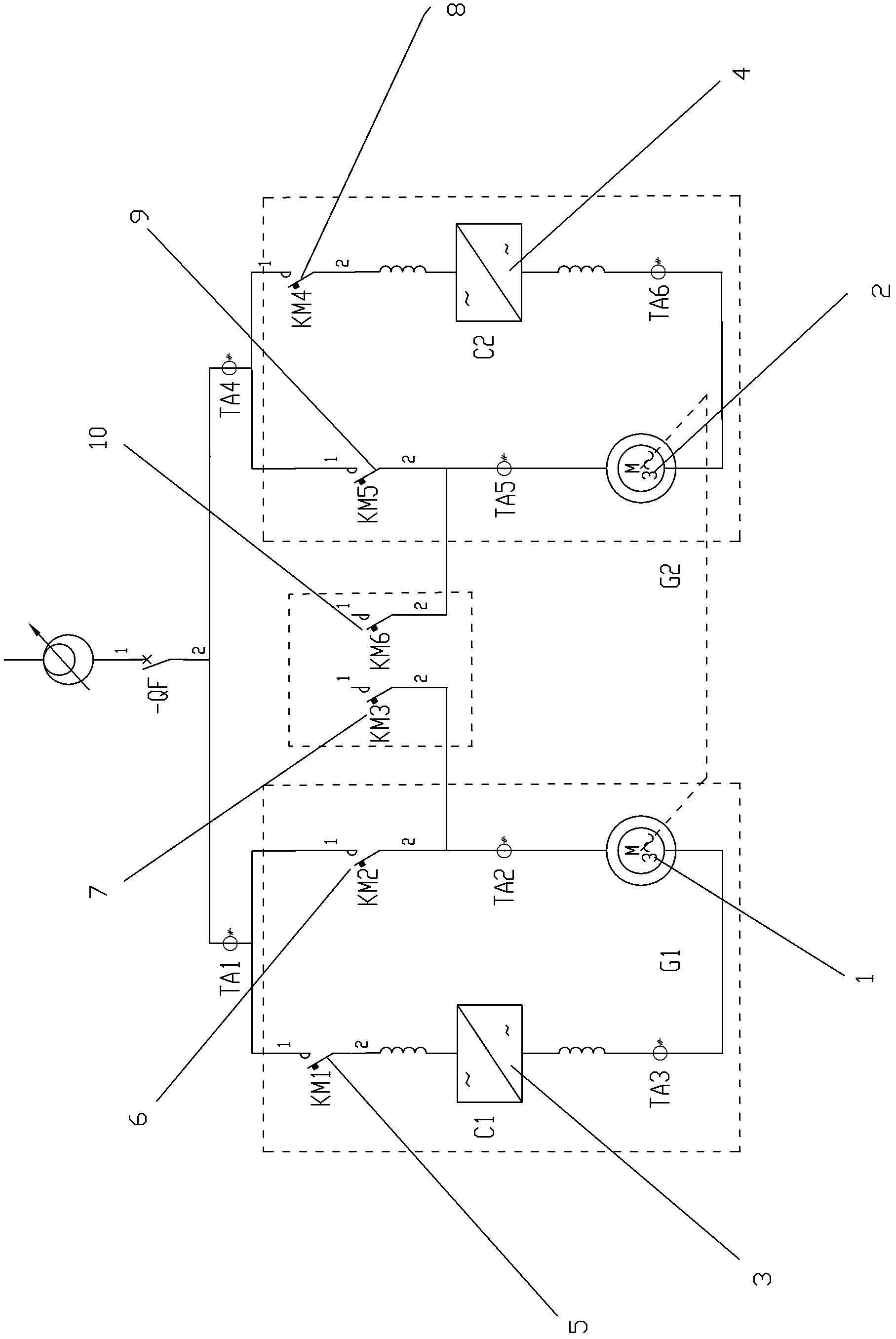

[0026] The present invention will be further described below in conjunction with the accompanying drawings and an embodiment. Such as figure 2 As shown, a double-fed motor test system includes a generator unit, a motor unit and a system start-up unit, the generator unit includes a motor A1 and a doubly-fed frequency converter A3, and the motor unit includes a motor B2 and a doubly-fed inverter Inverter B4, the system starting unit includes a stator short contactor A7 and a stator short contactor B10; the motor A1 and the motor B2 are double-fed motors of the same specification and model, and are rigidly connected by a shaft coupling; The motor A1 described above is connected in series with the doubly-fed inverter A3, the front-end contactor A5 of the doubly-fed inverter and the grid-connected contactor A6 of the doubly-fed motor in series to form a loop, and the stator short-circuit contactor A7 is connected between the motor A1 and the doubly-fed motor. On the cable between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com