led collimator device

A collimator, LED light source technology, applied in lighting devices, lighting device parts, instruments, etc., can solve non-compliance with requirements, reduce collection efficiency by collecting lenses, increase the size, complexity and cost of light-emitting devices, etc. problem, to achieve the effect of solving the divergence problem, simple manufacturing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

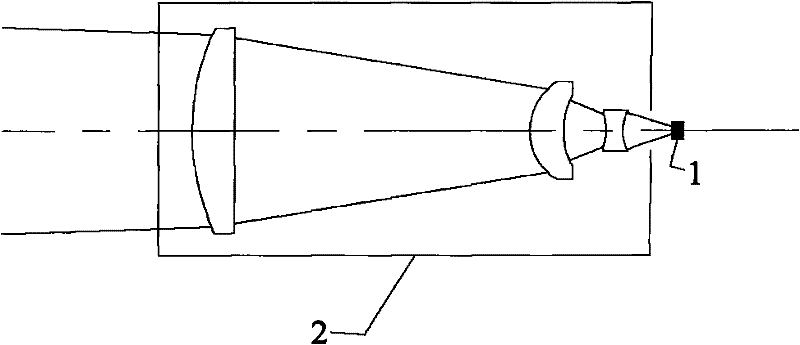

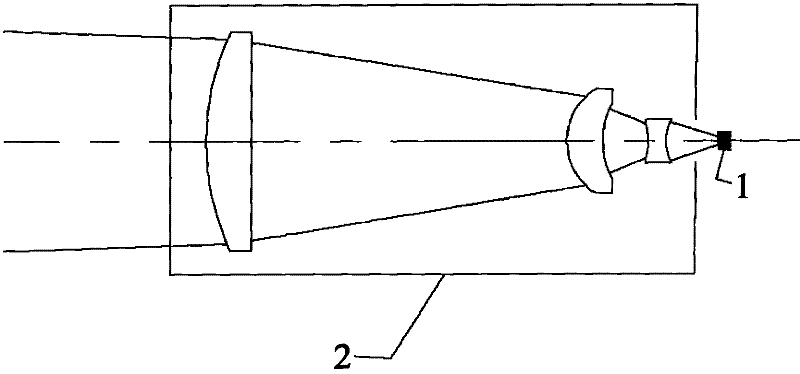

[0017] Such as figure 1 As shown, the LED collimator device includes an LED light source 1 and a collimator. The light collimator includes an optical lens and a lens barrel 2. The optical lens is placed in the lens barrel 2. There are 3 optical lenses arranged at intervals in sequence. The LED light source 1 is arranged at the incident window of the lens barrel 2, and the emission angle of the LED light source 1 is less than 60°.

[0018] The LED light source 1 can be a point light source or a surface light source, and the light emitted during its operation basically enters the incident window of the collimator. The collimator is designed as a barrel structure, and the light can obtain a uniform light intensity distribution within a certain range after passing through the collimator. The main direction of the incident light is parallel to the optical axis of the LED; the distance between the LED and the collimator of the light source is less than 1mm; the working distance of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Launch angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com