A zero-point calibration method for a two-degree-of-freedom high-speed parallel robot

A robot and degree-of-freedom technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as restricting the efficiency of the zero-point calibration process, reducing the automation degree of the calibration process, and difficulty in measuring noise and noise characteristics to improve robustness. and accuracy, improve efficiency, guarantee the effect of robustness and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described in detail below with reference to the accompanying drawings and specific implementation cases.

[0070] Taking the calibration system in the Chinese invention patent "A Zero Point Calibration Method of Two Degrees of Freedom High-speed Parallel Robot" (ZL201410364282.3) as an implementation example, the specific implementation of the present invention is as follows:

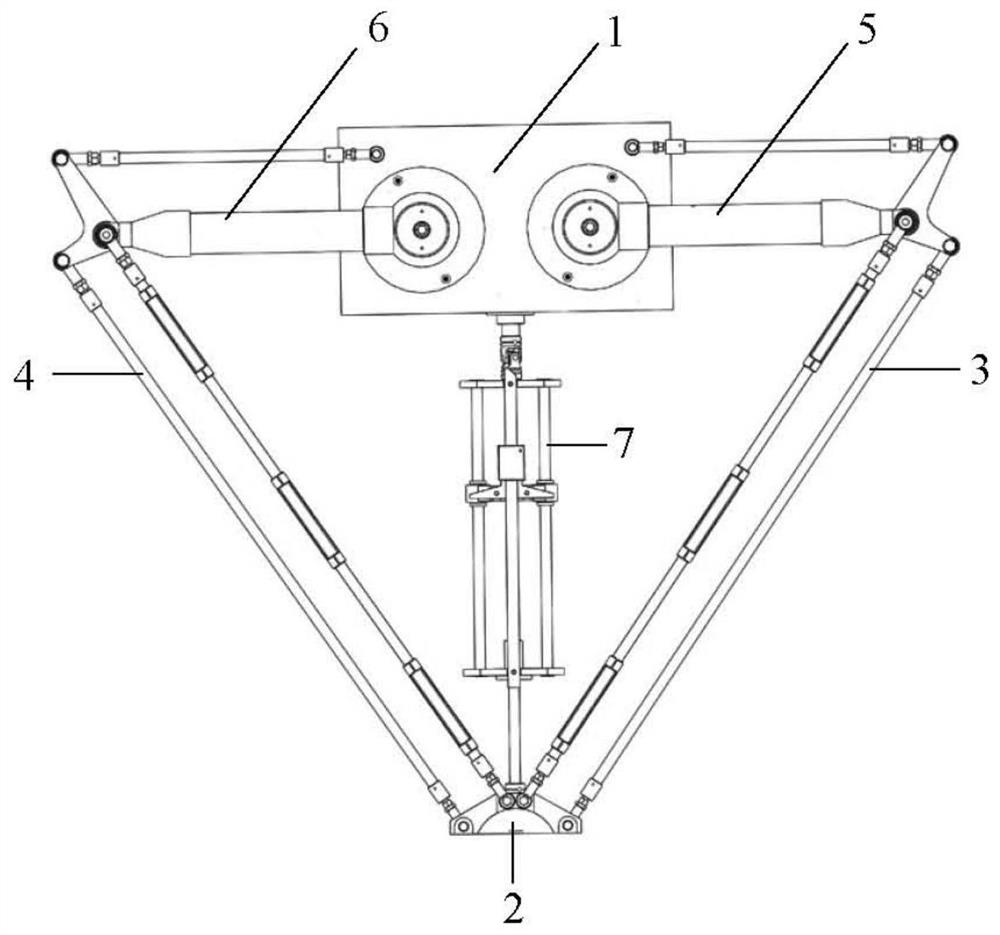

[0071] 1. Establish the mapping model between the robot zero point error and the end motion error

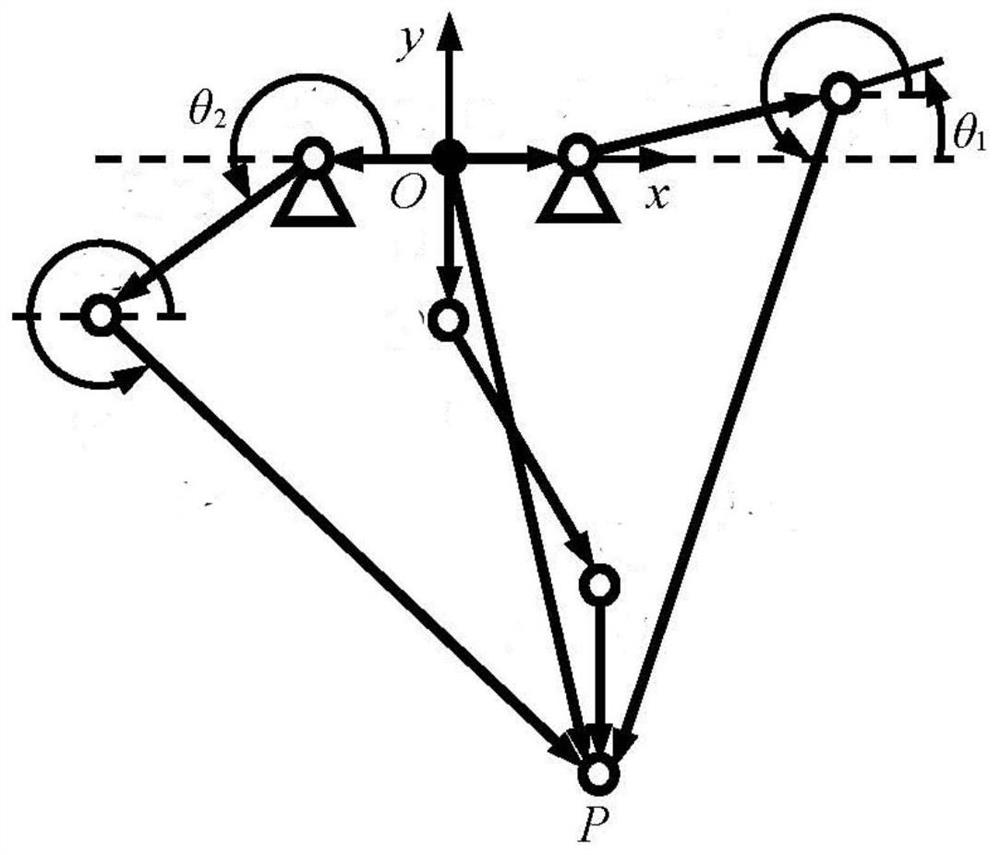

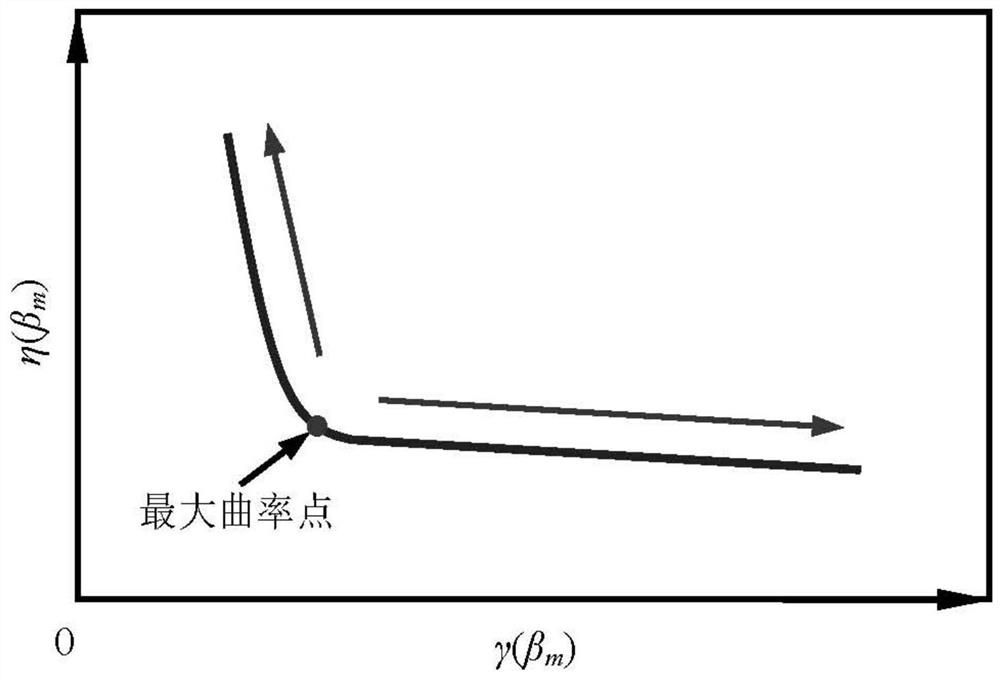

[0072] like figure 1 As shown, the two-degree-of-freedom high-speed parallel robot is composed of a static platform 1 , a moving platform 2 , a first moving branch 3 and a second moving branch 4 . A telescopic ruler 7 is installed between the static platform 1 and the moving platform 2, and the two ends of the telescopic ruler 7 are respectively connected with the static platform 1 and the moving platform 2 through a rotating pair. like figure 2 As shown, the dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com