A street light tube life monitoring system

A lamp life and monitoring system technology, applied in the direction of discharge tube testing, lighting devices, light sources, etc., can solve the problems of affecting road lighting, wasting electric energy, wasting manpower and material resources, etc., to achieve convenient road lighting, simple structure, and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

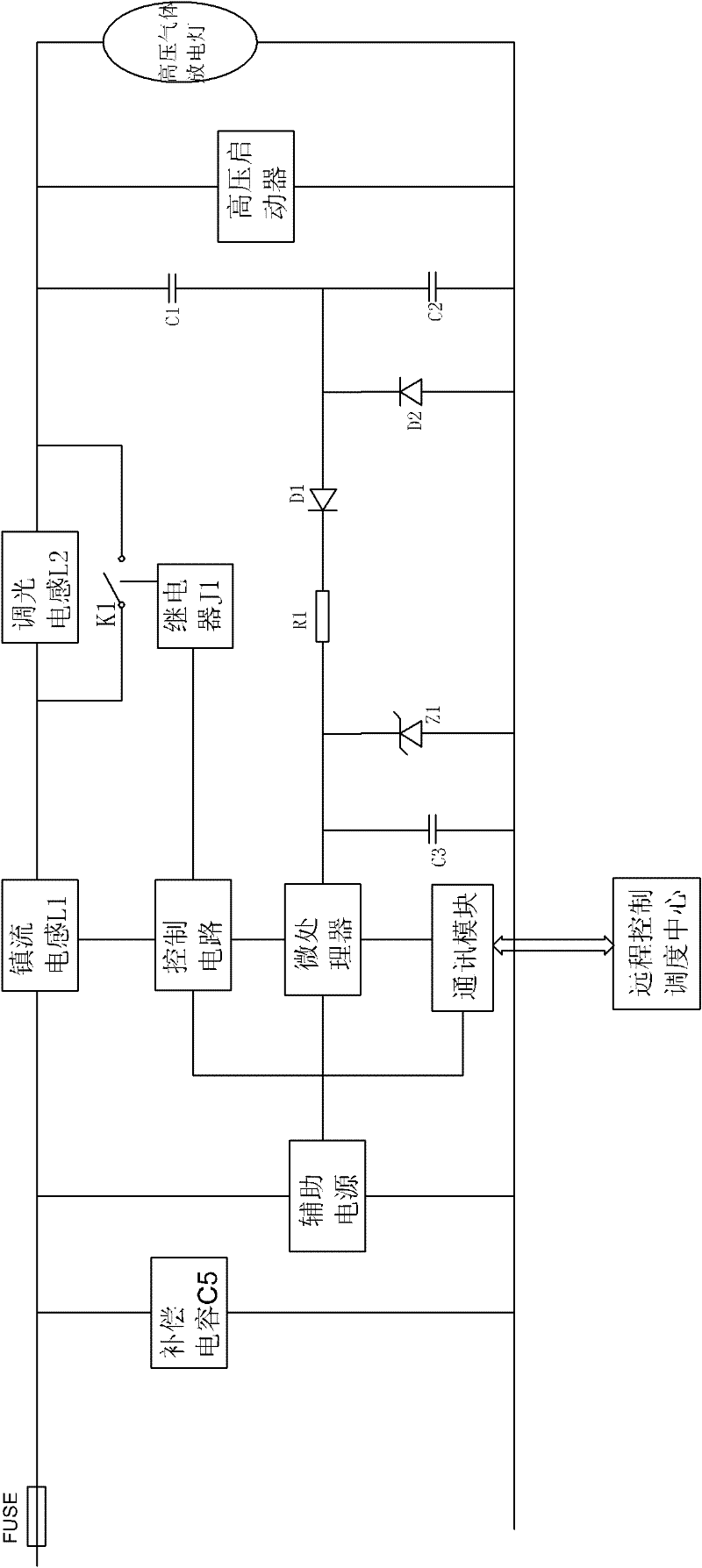

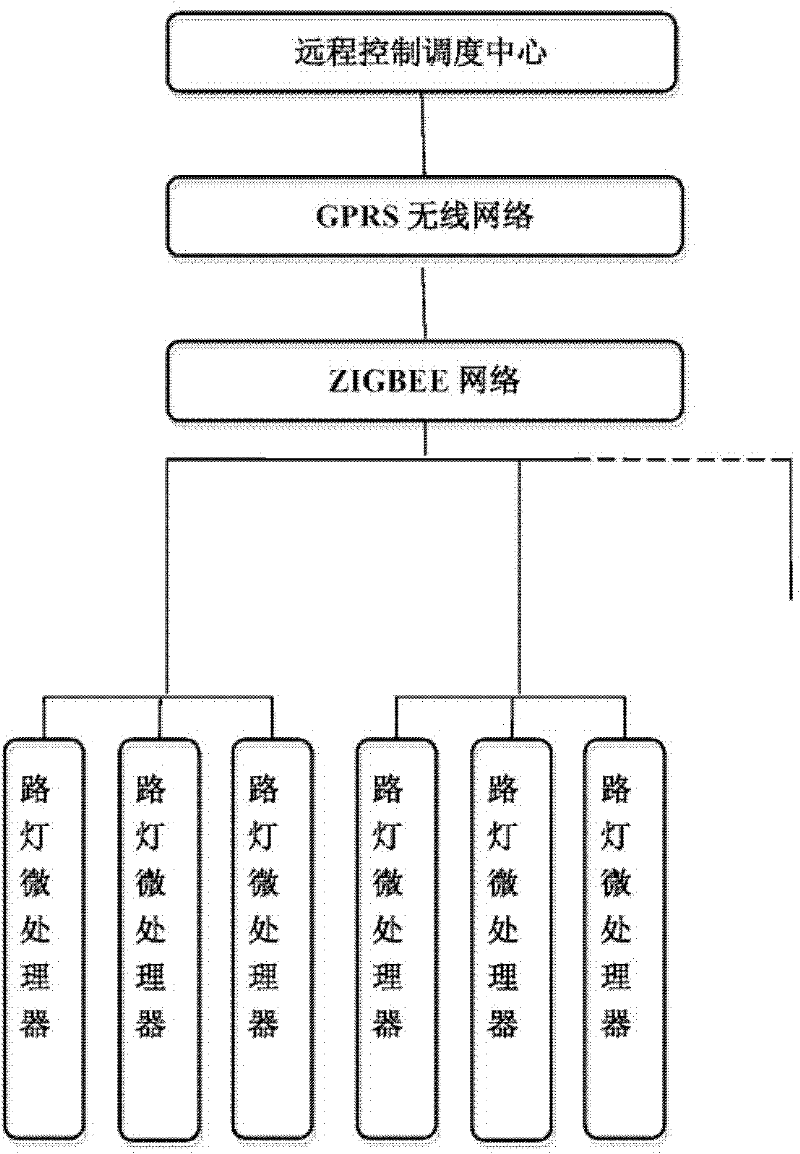

[0022] Such as figure 1 , a street lamp tube life monitoring system, including a ballast system and a remote control dispatch center, the ballast system includes a ballast inductor L1 connected to the lamp tube, a compensation capacitor C5 and a high-voltage starter; the remote control dispatch center through a communication network Connect the voltage detection circuit set at both ends of the lamp tube. The voltage detection circuit includes a voltage dividing capacitor C1, a voltage dividing capacitor C2, a detection diode D1, a filter capacitor C3, a resistor R1, a voltage regulator tube Z1, and a protection diode D2; the voltage dividing capacitor C1 and The voltage dividing capacitor C2 is connected in series to both ends of the lamp tube, the common end of the voltage dividing capacitor C1 and the voltage dividing capacitor C2 is connected to the positive pole of the detection diode D1, the negative pole of the detection diode D1 is connected to the resistor R1, the resis...

Embodiment 2

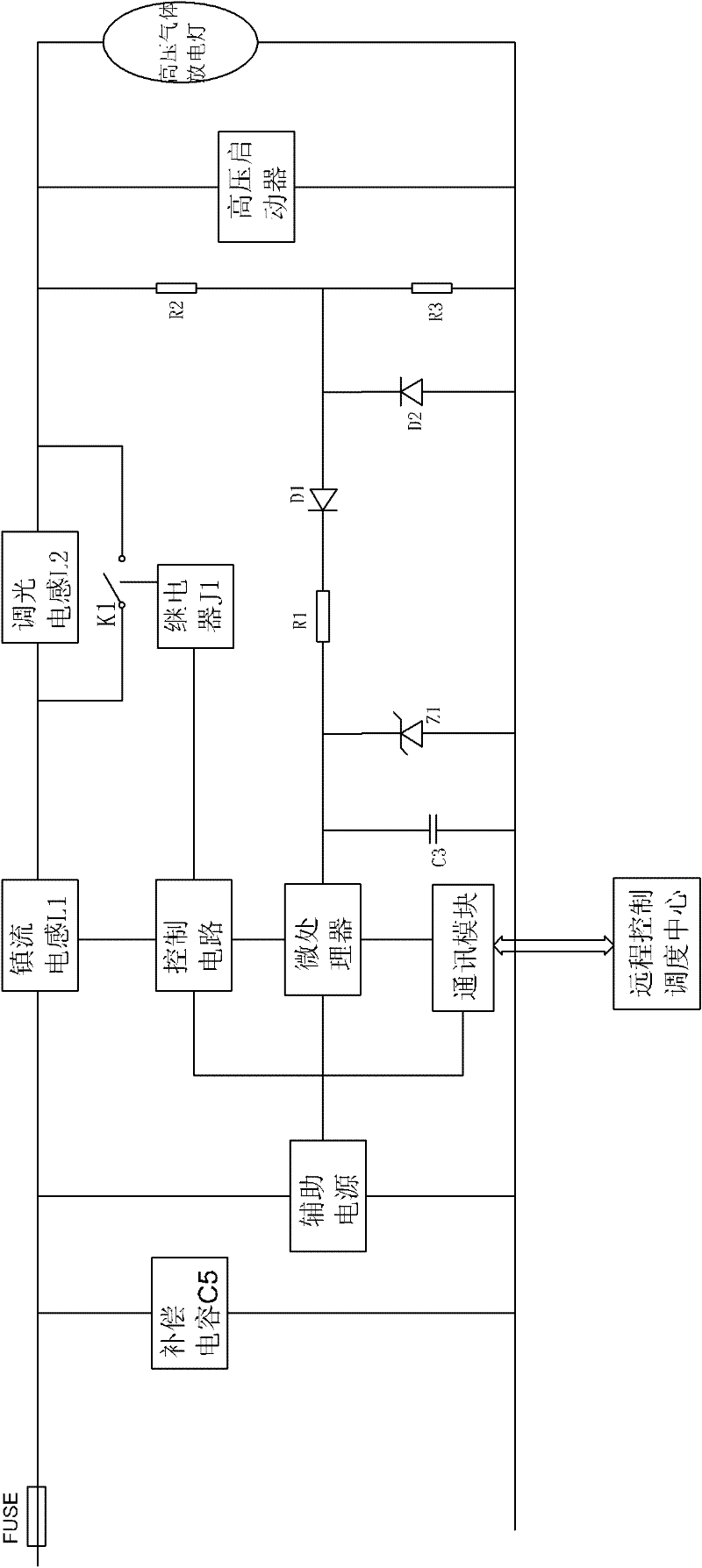

[0031] Such as figure 2 , a street lamp tube life monitoring system, including a ballast system and a remote control dispatch center, the ballast system includes a ballast inductor L1 connected to the lamp tube, a compensation capacitor C5 and a high-voltage starter; the remote control dispatch center through a communication network Connect the voltage detection circuit set at both ends of the lamp tube, the voltage detection circuit includes voltage divider resistor R2, voltage divider resistor R3, detection diode D1, filter capacitor C3, resistor R1, voltage regulator tube Z1, protection diode D2; voltage divider resistor R2 and The voltage divider resistor R3 is connected in series to both ends of the lamp tube, the common end of the voltage divider resistor R2 and the voltage divider resistor R3 is connected to the positive pole of the detection diode D1, the negative pole of the detection diode D1 is connected to the resistor R1, the resistor R1 is connected to the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com