Processing Technology of Small Diameter, Thin Wall, Deep Hole and High Precision Parts and Its Special Grinding Tools

A processing technology and small diameter technology, applied in the field of mechanical processing technology, can solve problems such as design requirements and processing difficulties of difficult cylinder parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

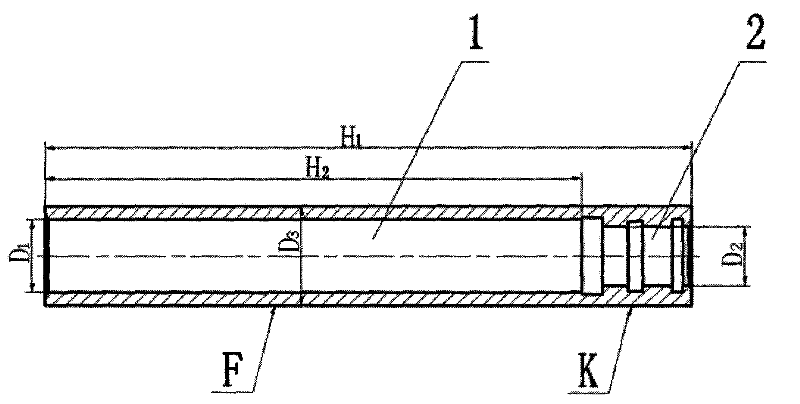

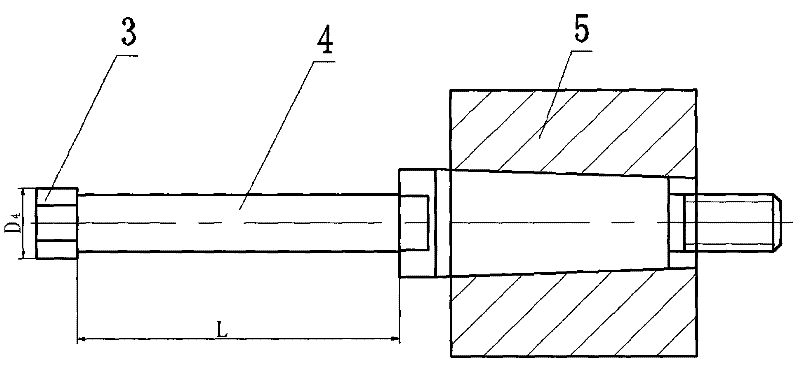

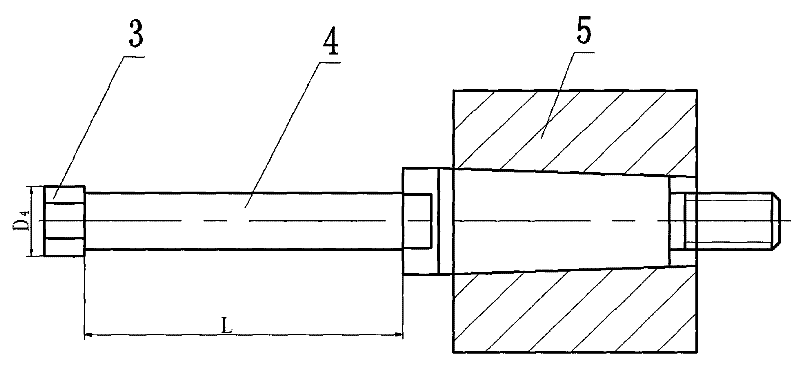

[0011] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, the step of the processing technology of the small-diameter thin-walled deep-hole high-precision part of this embodiment is:

[0012] Step 1. The blank is made of round steel, and the outer circle of the blank is processed by the turning process, and the end faces on both sides of the part are flattened to ensure that the total length of the part is H 1 , and drill a center hole at the center of the end faces on both sides; on the lathe, adopt the clamping method of tightening the center holes of the end faces on both sides, and turn the outer circle to the design diameter D 3 , during the turning process, use a dial gauge to make a calibration, to ensure that the straightness of the outer circle is less than or equal to 0.005mm, and the coaxiality is less than or equal to 0.005mm;

[0013] Step 2. Turning the inner hole. Clamp the part with a three-jaw chuck on the lathe, suppo...

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment differs from Embodiment 1 in that: the jaws of the three-jaw chuck in step 2 are wrapped with thin aluminum sheets. Prevent the jaws from directly acting on the outer circle of the part and destroying the surface finish of the part.

specific Embodiment approach 3

[0017] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: during rough turning in step 2, the inner hole turning tool with a relief angle of 4° to 6° is selected, and during finish turning, the relief angle is selected to be 8° ~12° inner hole turning tool. In order to reduce the friction between the flank and the part, avoid the increase of cutting heat and improve the surface roughness; when finishing the inner hole, the rake angle should be increased to make the cutting edge sharp, reduce deformation and friction, and generate less heat for cutting The temperature drop can save cutting effort and make the chip discharge smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com