Manufacturing process of ultra-thin natural stone composite board

A production process and technology of composite boards, applied in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of inability to achieve breakthrough in the thickness of finished products, long cycle of composite floors, inconvenient handling and installation, etc. The effect of fast construction and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The process of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

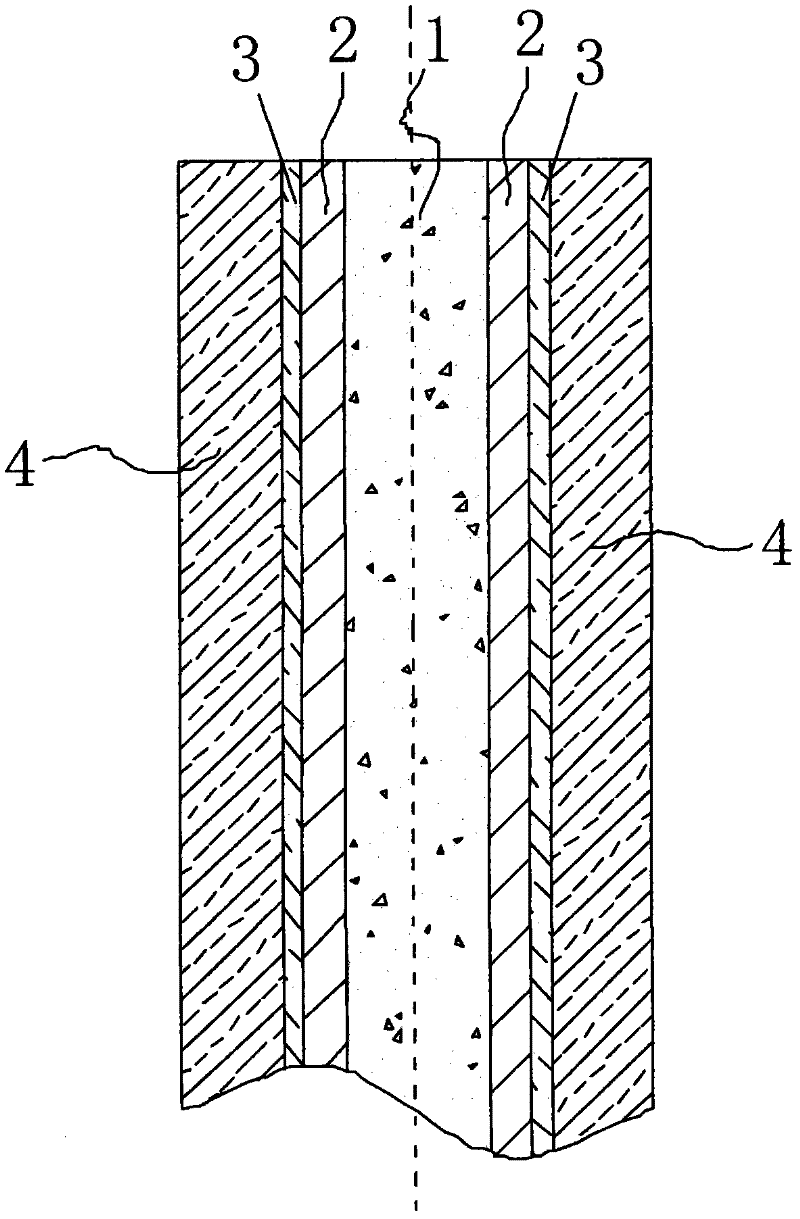

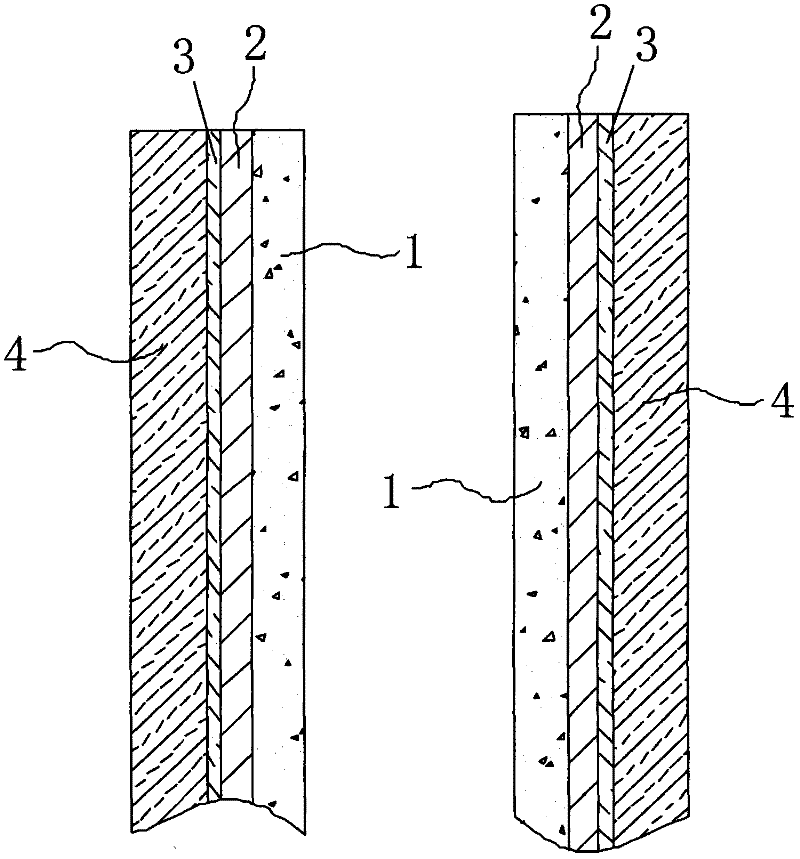

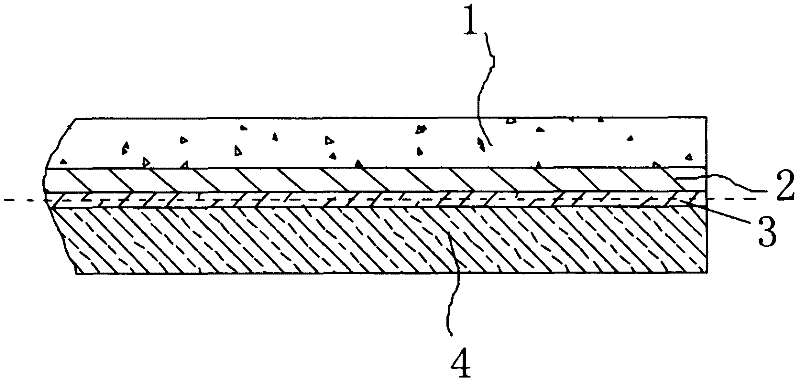

[0043] Such as Figure 1-Figure 5 It is a structural diagram of Embodiment 1 of the present invention.

[0044] An ultra-thin natural stone composite board manufacturing process, the process comprises the following steps:

[0045] a. Prepare the backing reinforcement layer 2 and the base plate 4;

[0046] The material of the backing reinforcement layer 2 is a fiberboard with light weight and high hardness, and the material of the base plate 4 is a metal structural board, preferably an aluminum honeycomb board with light weight and high strength.

[0047] b, the natural stone 1 is subjected to thickness-setting processing;

[0048] Carry out double-sided thickness-calibrating processing to natural stone 1 with a thickness-calibrating machine.

[0049] c. Fix the backing reinforcement layer 2 on both sides of the natural stone 1;

[0050] When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com