A whole vehicle automatic washing machine for engineering vehicles

A technology for automatic flushing and engineering vehicles, which is applied in the direction of vehicle exterior cleaning devices, etc., to achieve the effects of fast flushing, thorough flushing, and short flushing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

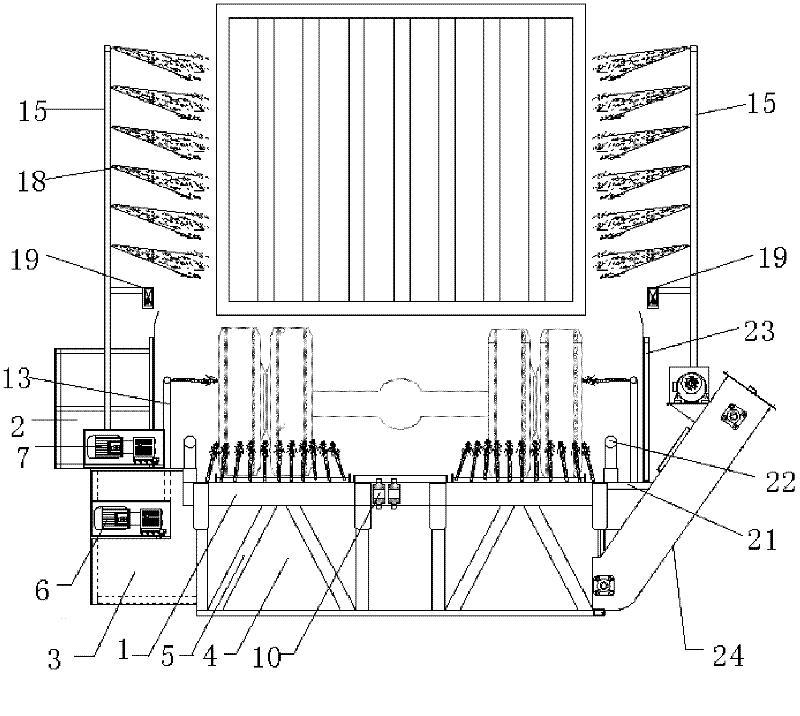

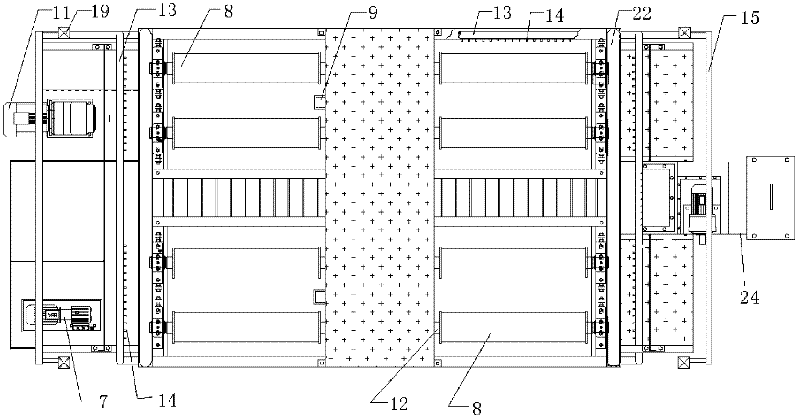

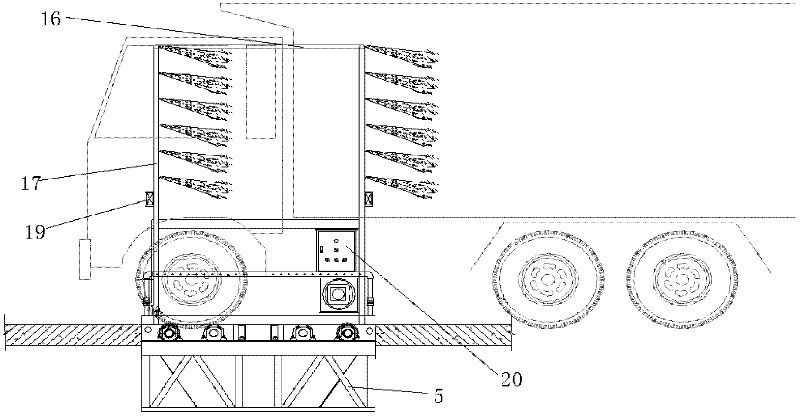

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] The overall structure of the engineering vehicle full-vehicle automatic washing machine provided by the invention is as follows: figure 1 As shown, the frame is a cuboid, the upper part of the frame is a washing table 1, and the lower part is a support frame 5, and the washing table 1 is located above the mud collection tank 4, and the frame adopts section steel welded into a truss structure. Water tank 3 and mud collection tank 4 are connected as a whole, between the two, filter screen and pool plate are arranged successively, and are communicated by filter screen, and the height of the bottom of pool plate apart from mud pool 4 bottoms is 20cm, mud pool 4 is wide at the top and narrow at the bottom, and its side wall is a sloping plate. The bottom of the mud collection tank 4 is an inclined plane, and the water tank 3 is equipped with a high-pressure water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com