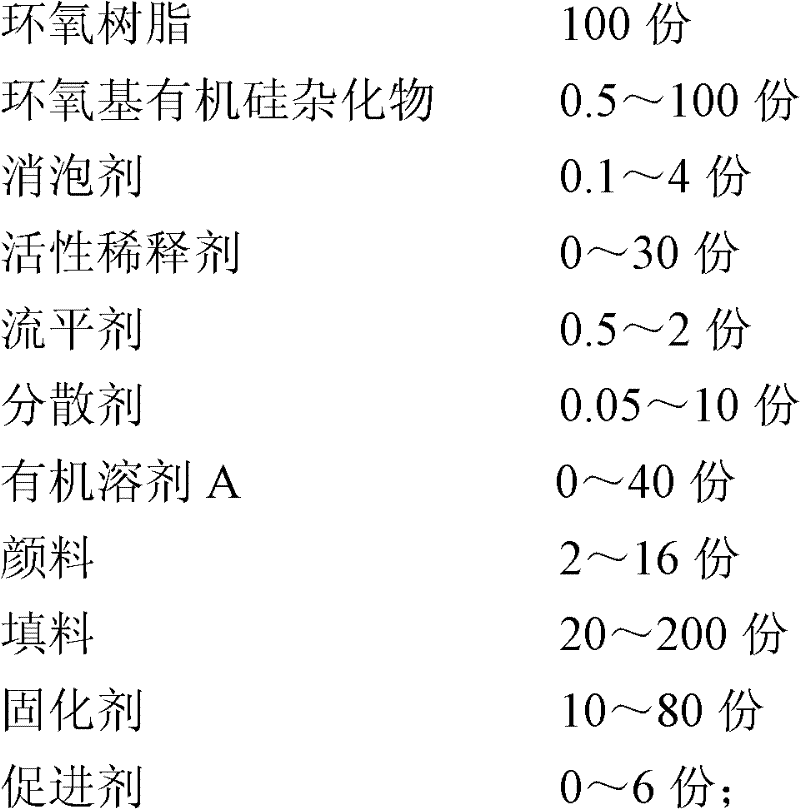

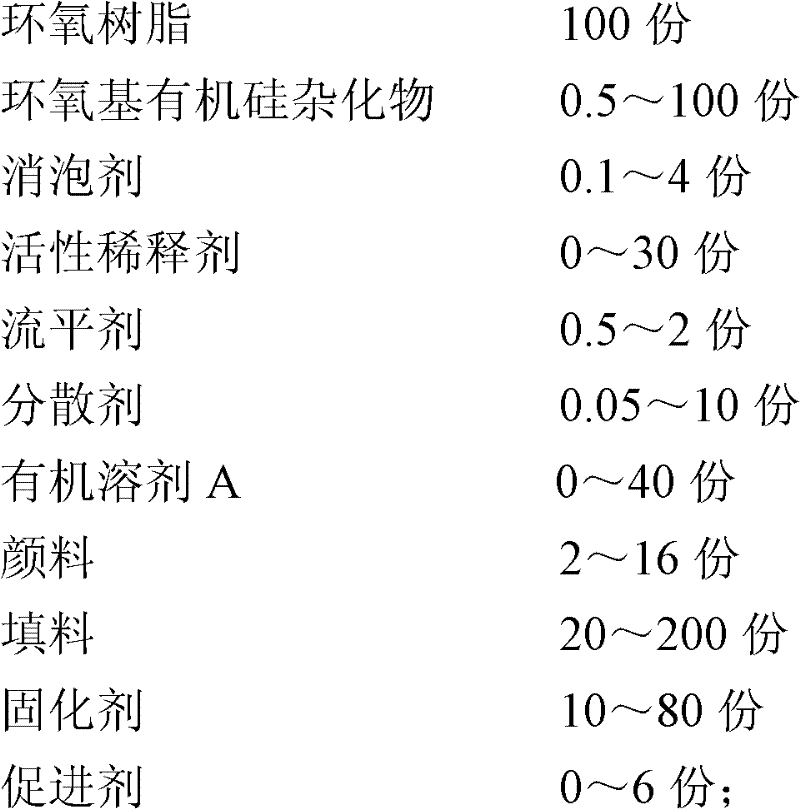

Epoxy flooring coating containing epoxide group organosilicon hybrid, its preparation method and its application

A technology of epoxy-based silicone and epoxy flooring, which is applied in the direction of epoxy resin coatings and coatings, can solve the problem that the modification effect of epoxy resin is not very obvious, and solve the problem of easy scratches and easy access to raw materials , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

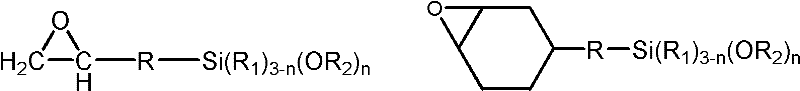

Method used

Image

Examples

Embodiment 1

[0043] (1) Mix 100g dimethyldiethoxysilane, 50g glycidoxypropyltrimethoxysilane (KH-560), 50g dioxane, 5g deionized water and 0.5g dibutyltin dilaurate After uniformity, hydrolyze and polycondense at 100°C for 2 hours, and remove small molecular substances such as dioxane and water by vacuum distillation to obtain epoxy-based organosilicon hybrids.

[0044](2) Bisphenol A type epoxy resin (E-51) 100g, defoamer BYK066 0.1g, propylene oxide butyl ether 20g, leveling agent EFKA3777 0.5g, dispersant BYK-P104 0.05g, titanium dioxide 16g, kaolin 20g, are placed in intensive mixer and mix homogeneously; Add the epoxy-based organosilicon hybrid compound 30g synthesized in the step (1) again, polyamine amide solidifying agent (Tianjin Laihe Commercial Development Co., Ltd. provides) 55g, 3g of 2-methylimidazole was mixed evenly with a high-speed mixer to obtain an epoxy-based organosilicon hybrid epoxy floor coating. Measure hardness with standard GB / T6739-1996 (pencil hardness test m...

Embodiment 2

[0046] (1) 80g diphenylsilanediol, 20g methyltrimethoxysilane, 200g 2-(3,4-epoxycyclohexane) ethyltrimethoxysilane, 500g dioxane, 100g deionized Water and 5g of stannous octoate were mixed evenly, then hydrolyzed and polycondensed at 80°C for 6 hours, and small molecular substances such as dioxane and water were removed by vacuum distillation to obtain an epoxy-based organosilicon hybrid.

[0047] (2) Put 100g of novolac epoxy resin, 0.6g of defoamer BYK066, 30g of propylene oxide phenyl ether, 2g of leveling agent EFKA3777, 2.5g of dispersant BYK-P105, 13g of iron oxide red, and 100g of talc powder in the Mix well in a strong mixer; add 0.5 g of epoxy-based organosilicon hybrids synthesized in step (1), 80 g of amino-terminated polyamides (provided by Xuzhou Zhongyan Science and Technology Industry Co., Ltd.), 2,4,6-tri(two Methylaminomethyl) phenol 5g, mix homogeneously with high-speed mixer, obtain the epoxy floor coating containing epoxy group organosilicon hybrid. The pe...

Embodiment 3

[0049] (1) 50g dimethyldimethoxysilane, 40g tetraethoxysilane, 10g trimethylmethoxysilane, 500g glycidoxyoctyltrimethoxysilane (X-12-692), 600g Ethanol, 120g of deionized water and 12g of dibutyltin diacetate were mixed evenly, then hydrolyzed and polycondensed at 50°C for 10 hours, and small molecular substances such as ethanol and water were removed by vacuum distillation to obtain epoxy-based organosilicon hybrids .

[0050] (2) Bisphenol A type epoxy resin (E-44) 100g, defoamer BYK066 0.8g, C12-C14 fatty alcohol glycidyl ether 10g, leveling agent EFKA3777 1.6g, dispersant BYK163 10g, carbon black 10g , 160g of talcum powder, placed in a strong mixer and mixed uniformly; then add 60g of epoxy-based organosilicon hybrids synthesized in step (1), 16g of triethylenetetramine, and mix uniformly with a high-speed mixer to obtain epoxy-group-containing Silicone hybrid epoxy floor coating. The pencil hardness of floor coating is 2H; Abrasion resistance is 0.02, and impact resist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap