Heat treatment quenching cooling device

A cooling device and cooling pool technology, applied in quenching devices, heat treatment equipment, manufacturing tools, etc., can solve the problems of unsatisfactory cooling effect, prone to safety accidents, unsatisfactory cooling effect, etc., to achieve ideal heat dissipation effect and not easy to safety accidents. , Conducive to the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

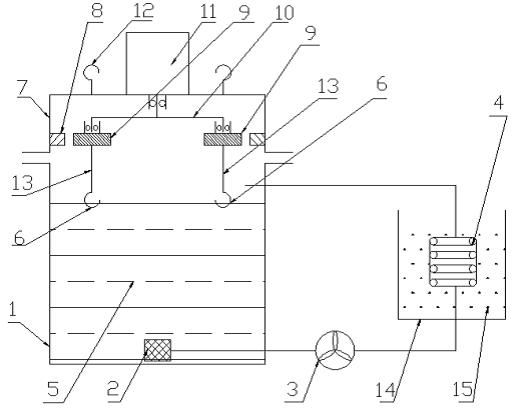

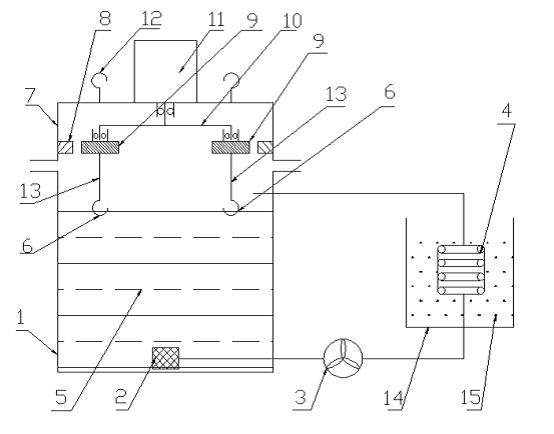

[0011] In the figure, the heat treatment quenching cooling device includes a cooling pool 1, an oil filter 2, an oil pump 3, a radiator 4, cooling oil 5, a hook 6, a box body 7, a large internal gear 8, a planetary gear 9, and a planetary gear carrier 10. The cooling system of motor 11, lifting frame 12, suspension shaft 13, cooling tank 14, circulating water 15, the present invention is provided with a cooling pool 1, oil filter 2, oil pump, 3 radiator 4, cooling oil 5, Cooling tank 14, the cooling system of circulating water 15, the cooling pool 1 of this invention is independent of each other, the oil inlet of oil pump 3 communicates with the bottom of cooling pool 1 through oil filter 2; The upper mouth of the cooling pool is connected, and cooling oil 5 is injected in the cooling pool. The cooling tank 14 is independent of the cooling pool 1. The radiator 4 is fixedly installed in the cooling tank 14, and the circulating water 15 is introduced in the cooling tank. At the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com