A frame type debris flow sand retaining dam and its construction method

A technology for sand control dams and debris flow, applied in the field of debris flow prevention and control, can solve problems such as uneven foundation settlement of sand control dams, difficulty in controlling construction quality, and affecting safe operation of the dam body, so as to reduce the strength of the dam body, save investment, and maintain The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

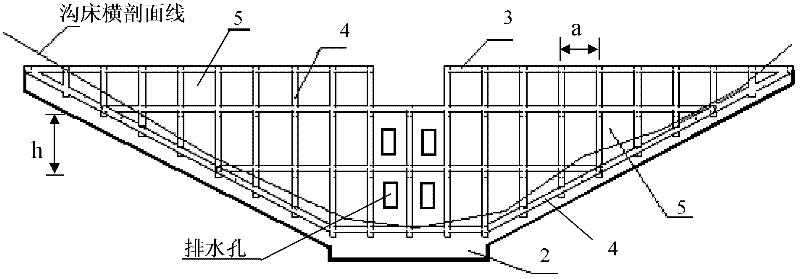

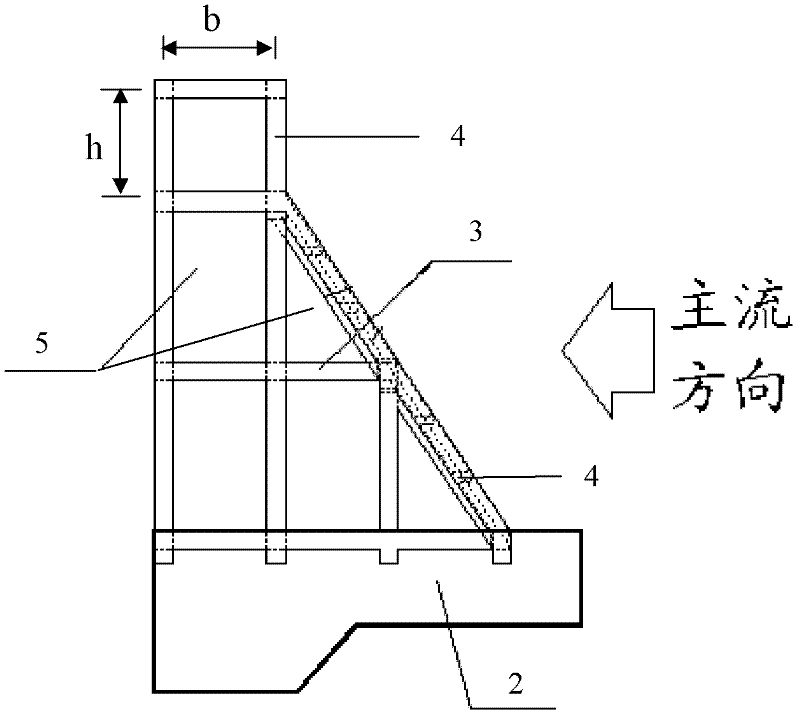

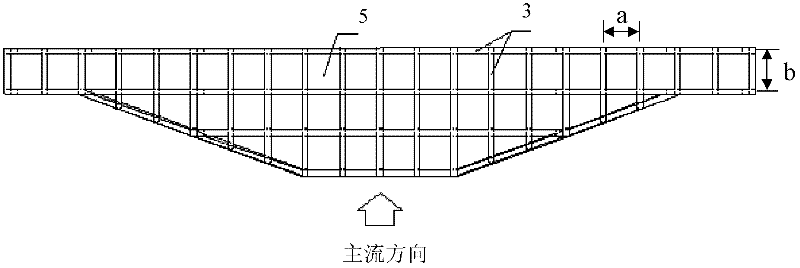

[0025] like figure 1 , figure 2 , image 3 , Figure 4 shown. The drainage area of a debris flow ditch is 24.2km 2 , in order to control debris flow disasters, it is planned to set up 15 valley squares, 1 control sand dam and 700m drainage channel in the middle of the basin. In order to make the sand control dam achieve the purpose of control type, the frame type debris flow sand control dam of the present invention is adopted. The frame-type debris flow sand control dam includes a dam body foundation 2 and a dam body body arranged on the dam body foundation 2, and a reinforced concrete frame 1 and masonry stones 5 filled between the frame 1 constitute the dam body body. A number of reinforced concrete columns are connected vertically and horizontally on the horizontal plane to form a layer of horizontal beams 3. The frame 1 includes five layers of horizontal beams 3 and vertical beams 4 formed of reinforced concrete columns between every two layers of horizontal beams...

Embodiment 2

[0029] The same as Embodiment 1 will not be repeated, the difference is: the height of the sand retaining dam is 6.0m, the length of the dam axis perpendicular to the mainstream direction is 24m, the net dam height from the overflow to the dam body foundation 2 is 4.0m, and the width of the dam crest is 4.0m. is 2.0m, and the slope gradient inside the dam body is 1:0.7. The length a of the reinforced concrete column on the horizontal beam 3 and along the length direction of the sand control dam is 2.0m, the length b of the reinforced concrete column on the horizontal beam 3 and along the mainstream direction is 2.0m, and the reinforced concrete column on the horizontal beam 3 The cross-sectional area formed between them is 0.3×0.3m 2 The length h of the reinforced concrete column forming the vertical beam 4 is 2.0m, and the cross-sectional area formed between the vertical beam 4 and the horizontal beam 3 is 0.3×0.3m 2 . The overall volume reinforcement ratio of the reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com