A sound insulation structure with perforated panels

A perforated plate and sound insulation technology, which is applied in the direction of sound insulation and building components, can solve the problems of improving the sound insulation of sound insulation structures and sound insulation products, so as to improve the sound insulation performance, weaken the resonance effect, and achieve good insulation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

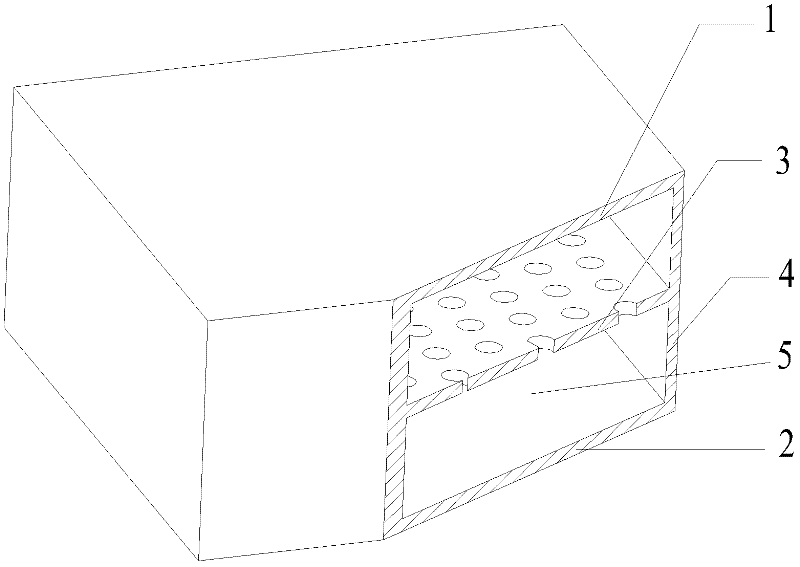

Embodiment 1

[0025] refer to figure 1 . Both the upper panel 1 and the lower panel 2 are glass plates (the glass plates include various glass plates such as quartz glass and organic glass). The thicknesses of the upper panel 1 and the lower panel 2 are respectively selected according to actual needs, such as 3 mm, 5 mm, 8 mm and so on. The perforated plate 3 is also a glass plate, and its thickness is a certain applicable value, such as 2 mm, 3 mm, 1.5 mm and so on. The hole diameter of the perforated plate 3 can be selected according to the thickness of the plate and the target anechoic frequency band, which is generally 0.2-3 mm. The hole diameter of the perforated plate 3 should be as small as possible under the premise of meeting the actual requirements. The perforation rate of the perforated plate 3 can be selected according to actual needs, and is generally 0.3%-6%. The perforation rate of the perforated plate 3 should be as small as possible under the premise of meeting the actu...

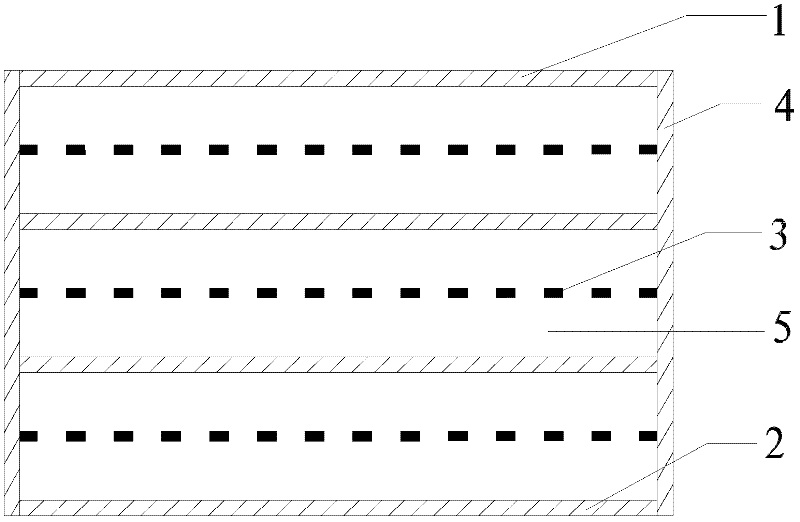

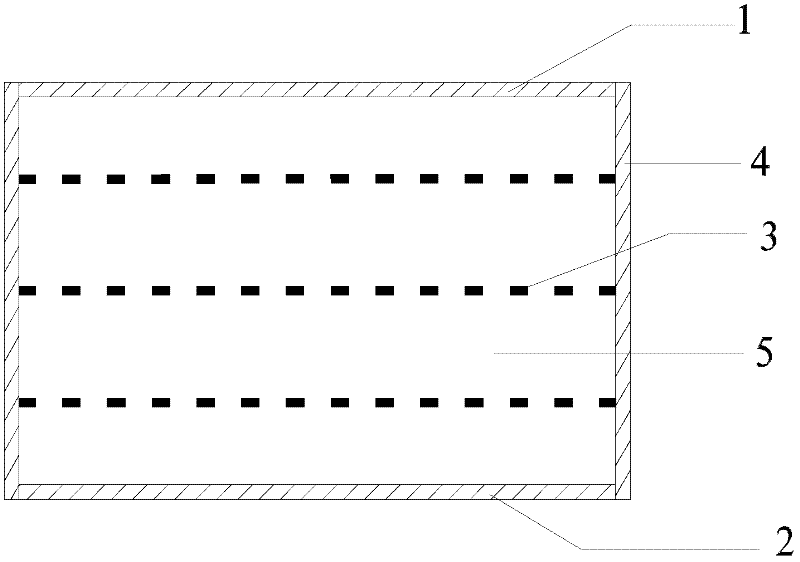

Embodiment 2

[0028] refer to figure 2 . The upper panel 1, the lower panel 2, the side panel 4, and the other two non-porous panels that play the role of the upper and lower panels in the figure are all steel plates, and the thickness of each panel can be a certain value, such as 1 mm, 2 mm, etc. The three perforated plates 3 in the figure can be thin steel plates with a thickness of 0.8 mm, a perforation diameter of 0.2-1 mm, and a perforation rate of 0.5%-5%. The distance between each perforated plate 3 and the adjacent upper and lower panels may be equal to an appropriate value, such as 5 cm, 8 cm or 20 cm. The cavity 5 formed by the three perforated plates 3 and their adjacent panels is filled with sound-absorbing materials, such as glass wool, polyurethane sponge and the like. The sound insulation structure produced by this scheme has a good sound insulation effect on medium and low frequency sounds, and has the characteristics of wide frequency band and high sound insulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Perforation aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Perforation aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com