Separate heat-insulating exhaust sound-absorbing device and refrigeration compressor using it

A technology of refrigeration compressors and noise reduction devices, which is applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., to achieve the effects of reducing heat transfer, reducing material costs, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The following is attached Figure 1-17 The embodiment of the present invention is described further, but does not limit the present invention.

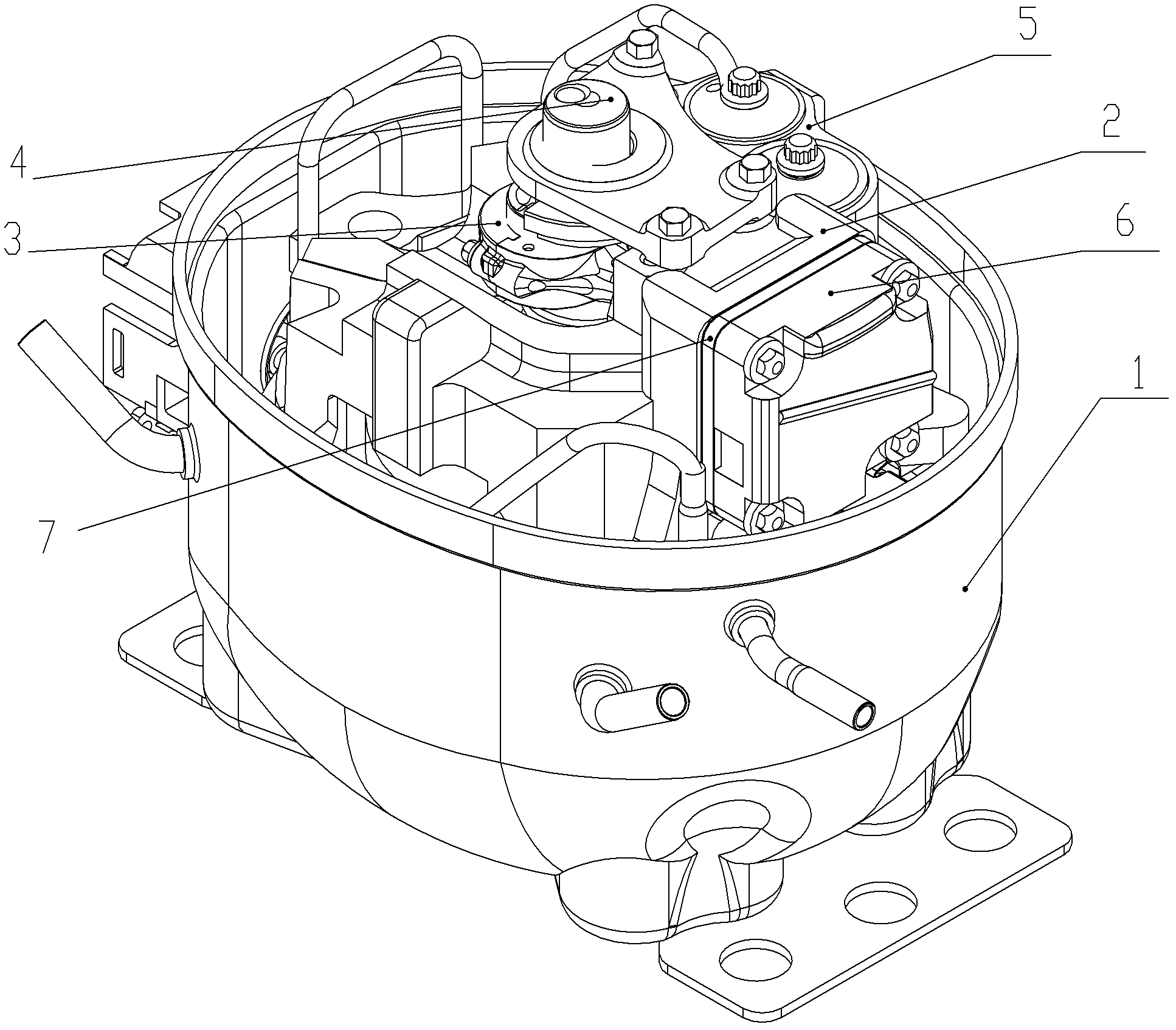

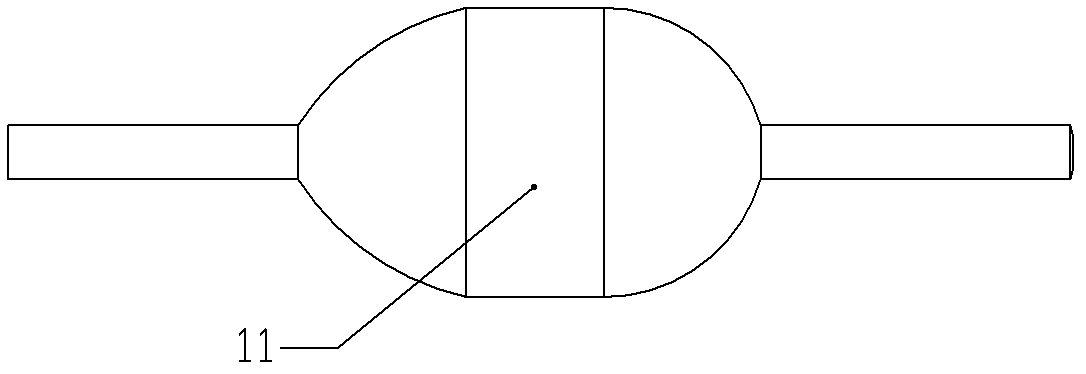

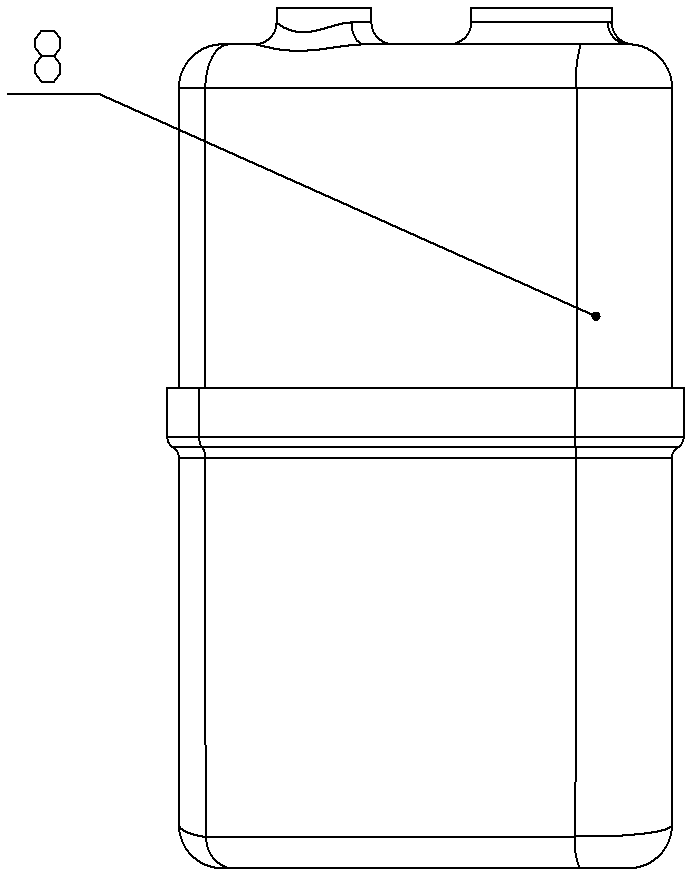

[0052] Such as Figure 3-4 , 5-14, the exhaust muffler device 8 of the present invention is arranged outside the cylinder block 14, and the upper chamber 9 and the lower chamber 10 are formed by stamping two pieces of metal materials, and the upper chamber 9 and the lower chamber 10 are fastened together. The metal cavity is formed by welding, and the metal cavity is in the shape of a cuboid, or other conventional shapes, such as ellipsoid, circle, cube, etc. The most important feature is that a non-metallic material casing 12 is installed outside the metal cavity. This casing 12 can be made separately (such as injection molding), or it can be co-cast with the metal cavity by injection molding. Electroplating and other chemical processes cover the outer surface of the metal cavity with non-metallic materials. The non-metalli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com